Titanium billet is a versatile material widely used in various industries due to its exceptional strength, light weight, and corrosion resistance. As a key raw material, it plays a crucial role in the manufacturing of components for aerospace, automotive, medical, and other high-performance applications. This article explores the advantages of titanium billet and its applications, helping manufacturers understand why it is a preferred choice for high-quality production.

What Is Titanium Billet?

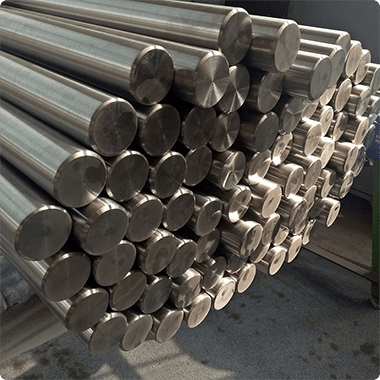

Titanium billet is a semi-finished product made from raw titanium, typically produced through forging or casting processes. It serves as a primary raw material for further manufacturing into components and parts. Titanium billets are widely used in industries that require materials with unique characteristics such as high strength, light weight, and excellent resistance to corrosion and extreme temperatures.

Titanium Billet Manufacturing Process

Titanium Extraction

- The production of titanium billet begins with the extraction of titanium from ores like ilmenite or rutile. Titanium is extracted through the Kroll process, which involves reducing titanium tetrachloride (TiCl4) with magnesium to produce titanium sponge, a pure form of titanium.

Melting and Alloying

- The titanium sponge is then melted in a vacuum arc furnace or an electron beam furnace to remove impurities and achieve homogeneity. During this melting stage, alloying elements such as aluminum, vanadium, or molybdenum may be added to improve specific properties of titanium, such as strength, corrosion resistance, and heat tolerance. The resulting product is titanium ingots.

Forming Billets

- The titanium ingots are further processed through forging or casting to form billets. Forging involves compressing and shaping the heated ingot to refine its grain structure, which improves mechanical properties like strength and toughness. Casting is an alternative process used depending on the specific application requirements.

Characteristics of Titanium Billet

High Strength-to-Weight Ratio

- Titanium billet is renowned for its high strength while being significantly lighter compared to other metals like steel. This strength-to-weight ratio makes it highly advantageous for industries that prioritize weight reduction without compromising mechanical integrity.

Corrosion Resistance

- Titanium naturally forms a protective oxide layer on its surface, giving it exceptional resistance to corrosion. This property makes titanium billet ideal for use in harsh environments, such as marine, chemical, and medical applications where exposure to corrosive agents is common.

Heat Resistance

- Titanium billet maintains its strength and stability even at high temperatures, which is crucial for industries such as aerospace where components must withstand extreme heat without degrading.

Biocompatibility

- Titanium is biocompatible, meaning it is non-toxic and not rejected by the human body. This characteristic makes titanium billet a preferred choice for medical implants and devices that come in direct contact with human tissue.

Grades of Titanium Billet

Titanium billets come in different grades, each suited to specific applications:

Commercially Pure (CP) Titanium Billet

- CP titanium billets contain unalloyed titanium and are categorized by their corrosion resistance, ductility, and moderate strength. They are typically used in applications like marine components, chemical processing equipment, and medical implants, where corrosion resistance is crucial.

Titanium Alloy Billets

- Titanium alloy billets, such as Grade 5 (Ti-6Al-4V), contain alloying elements like aluminum and vanadium to enhance properties like strength, toughness, and heat resistance. These alloys are ideal for aerospace components, automotive parts, and industrial equipment that require superior performance under extreme conditions.

Why Is Titanium Billet Important for Manufacturers?

Raw Material Versatility

- Titanium billet serves as a versatile starting material that can be machined, forged, or extruded to produce various parts. Its adaptability allows manufacturers to create components that meet specific performance criteria in different industries.

Precision Manufacturing

- Titanium billets are particularly well-suited for precision manufacturing processes. Their uniform structure and mechanical properties allow them to be machined into complex shapes while maintaining tight tolerances, which is essential for industries like aerospace and medical device production.

Performance Enhancement

- The use of titanium billet as a base material leads to finished products that are both lightweight and durable, providing significant performance advantages. This is especially relevant for aerospace and automotive industries, where reducing weight directly impacts fuel efficiency and overall performance.

Advantages of Using Titanium Billet in Manufacturing

1. Enhanced Product Performance

The use of titanium billet in manufacturing results in components that are lightweight yet strong, enhancing product performance. This is especially beneficial in industries like aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance.

2. Long-Lasting Durability

Titanium’s natural corrosion resistance ensures that products made from titanium billet have a longer lifespan compared to those made from other metals. This durability reduces maintenance requirements and replacement costs, providing long-term value for manufacturers and end-users.

3. Versatility in Applications

Titanium billet can be used to manufacture a wide variety of components, from aircraft parts to medical implants. Its versatility allows manufacturers to cater to different markets, including aerospace, automotive, medical, and marine industries.

4. Reduced Material Weight

Compared to traditional materials like steel, titanium billet provides significant weight savings without sacrificing strength. This reduction in weight is crucial in industries where minimizing mass is essential, such as aerospace and automotive manufacturing.

5. High Machinability

Titanium billet can be easily machined into complex shapes, making it a preferred material for precision components. Its machinability allows manufacturers to create intricate parts while maintaining high-quality standards.

Applications of Titanium Billet

1. Aerospace Industry

- Application Environment: Titanium billet is extensively used in the aerospace industry to manufacture components like turbine blades, airframe structures, and landing gear. The material’s high strength-to-weight ratio and heat resistance make it suitable for critical aerospace parts that need to withstand extreme conditions.

- Key Characteristics: Lightweight yet strong, resistant to heat and corrosion, ensuring reliability and safety in aerospace applications.

2. Automotive Industry

- Application Environment: Titanium billet is used in high-performance automotive parts, such as engine components, exhaust systems, and suspension parts. The use of titanium helps reduce the overall weight of the vehicle, leading to improved fuel efficiency and performance.

- Key Characteristics: Provides weight reduction, high strength, and resistance to corrosion, contributing to improved vehicle dynamics and longevity.

3. Medical Industry

- Application Environment: Titanium billet is widely used in the medical field for manufacturing implants, surgical instruments, and dental devices. Its biocompatibility makes it ideal for implants like hip joints, bone plates, and dental screws.

- Key Characteristics: Non-toxic, biocompatible, resistant to corrosion, ensuring safety and compatibility with the human body.

4. Marine Industry

- Application Environment: Titanium billet is used in marine environments to manufacture components such as propeller shafts, valves, and underwater housings. Its resistance to saltwater corrosion makes it an ideal material for marine applications.

- Key Characteristics: Resistant to corrosion in saltwater, ensuring durability and long-term reliability in harsh marine environments.

5. Chemical Processing Industry

- Application Environment: Titanium billet is used to manufacture equipment for chemical processing, such as heat exchangers, pumps, and valves. The material’s resistance to corrosion by chemicals ensures the longevity of components used in harsh chemical environments.

- Key Characteristics: Corrosion resistance to chemicals, heat resistance, providing long-lasting performance in aggressive processing environments.

FAQs Section

- What Is Titanium Billet Used For?

Titanium billet is used to manufacture components for industries like aerospace, automotive, medical, marine, and chemical processing, thanks to its strength, corrosion resistance, and versatility. - Why Is Titanium Billet Preferred in Aerospace Manufacturing?

Titanium billet is preferred for its high strength-to-weight ratio, heat resistance, and ability to withstand extreme conditions, making it ideal for critical aerospace components. - How Does Titanium Billet Benefit the Automotive Industry?

Titanium billet helps reduce vehicle weight, improves fuel efficiency, and enhances performance while providing high strength and corrosion resistance for automotive components. - Is Titanium Billet Safe for Medical Implants?

Yes, titanium billet is biocompatible, non-toxic, and safe for use in medical implants, making it suitable for direct contact with human tissue. - What Makes Titanium Billet Suitable for Marine Applications?

Titanium billet’s resistance to saltwater corrosion makes it ideal for marine components that need to withstand harsh ocean environments. - Can Titanium Billet Be Machined Easily?

Yes, titanium billet has high machinability, allowing manufacturers to create complex, precision components for various industries. - What Are the Advantages of Using Titanium Billet Over Steel?

Titanium billet offers a higher strength-to-weight ratio, corrosion resistance, and heat resistance compared to steel, making it more suitable for high-performance applications. - Is Titanium Billet Cost-Effective for Manufacturers?

While titanium billet is initially more expensive, its long-term durability, reduced maintenance, and weight-saving benefits make it cost-effective in the long run. - How Does Titanium Billet Perform Under High Temperatures?

Titanium billet maintains its strength and stability under high temperatures, making it ideal for applications in aerospace and chemical processing. - Why Is Titanium Billet Used in Chemical Processing Equipment?

Titanium billet is resistant to corrosion by various chemicals, ensuring long-lasting performance for components used in aggressive chemical environments.

Conclusion

Titanium billet offers numerous advantages for manufacturers, including a high strength-to-weight ratio, corrosion resistance, heat resistance, and biocompatibility. These properties make it an ideal material for a wide range of applications, from aerospace and automotive parts to medical implants and marine components. By choosing titanium billet, manufacturers can produce high-quality, durable products that meet the demands of various industries while providing long-term value and performance.

One Response