Protecting vital metal structures from corrosion is a constant battle. Choosing the wrong protection method can be a costly mistake, leading to premature failure and expensive repairs. So, how do you choose correctly?

The most common metals used as sacrificial anodes are zinc, magnesium, and aluminum alloys. These metals are more electrochemically reactive than the structure they protect (like a steel hull), causing them to corrode preferentially and "sacrifice" themselves.

As someone deeply involved in the metal industry—and based in Baoji, China’s “Titanium Valley”—I often get asked about sacrificial anodes, especially by customers working in marine, pipeline, or water tank protection systems. While my main focus is on inert anodes made from titanium, understanding sacrificial anodes is just as important for providing complete corrosion control solutions. These anodes work by being consumed over time and must be replaced, unlike inert titanium anodes designed for long-term systems. Understanding the full spectrum is how we deliver smart recommendations to our clients worldwide.

What metals can be used as a sacrificial anode?

Are you trying to figure out which metals will effectively sacrifice themselves to protect your equipment? The options are specific and chosen for their unique chemical properties that prevent corrosion on more critical parts.

The primary metals used as sacrificial anodes are zinc, magnesium, and aluminum alloys. These metals are more electrochemically active, meaning they corrode preferentially to protect less active metals like steel in different environments.

The science behind sacrificial anodes is based on the galvanic series, which ranks metals by their electrochemical potential. A sacrificial anode must be less noble (more reactive) than the metal it is protecting. When two different metals are connected in an electrolyte like seawater, the more reactive metal becomes the anode and corrodes, while the less reactive metal becomes the cathode and is protected. The three main choices—zinc, magnesium, and aluminum alloys—are selected for this reason. They are all significantly more reactive than steel. This is the opposite of a material like titanium, which is highly noble. Titanium’s exceptional corrosion resistance makes it ideal for long-lasting components in marine environments, but it is not suitable for use as a sacrificial anode [1][4][7].

Common Sacrificial Anode Materials

Here’s a look at the most common options I discuss with clients who are considering sacrificial protection:

| Material | Best Environment | Key Characteristics |

|---|---|---|

| Zinc (Zn) | Seawater (Saltwater) | A reliable and traditional choice for ship hulls and offshore structures. Performs predictably in saltwater. |

| Magnesium (Mg) | Freshwater & Buried Structures | Has the highest driving voltage, making it effective in higher-resistivity environments like freshwater. |

| Aluminum (Al) Alloys | Seawater & Brackish Water | Offers a higher capacity and is lighter than zinc, making it very efficient for large structures like offshore platforms [10]. |

What material can be used as an anode?

Is the term "anode" causing confusion? An anode isn’t always a material that gets consumed. The choice of material completely changes the anode’s function, from a consumable part to a permanent one.

Many materials can be anodes, but they fall into two main types. Sacrificial anodes include zinc, aluminum, and magnesium. Inert anodes, which are not consumed, include MMO-coated titanium and platinized titanium.

In my work, I deal with both types of anodes, and it’s crucial to understand the difference. The choice depends entirely on the type of cathodic protection system you are designing. One is a simple, passive system, while the other is an active system that requires an external power source. I often help clients decide which strategy is better for their long-term goals. While a sacrificial anode is simple, an inert anode system offers more control and a much longer lifespan, reducing maintenance costs over time [2][3][5].

Sacrificial (Galvanic) Anodes

These anodes are the core of a galvanic cathodic protection system. They are made from metals like zinc, aluminum, or magnesium, which have a more negative electrochemical potential than the structure being protected (usually steel). Because of this difference, a natural galvanic cell is created when they are placed in an electrolyte. The anode corrodes, providing protective current to the steel structure. This is a simple and reliable method that requires no external power.

Inert (Impressed Current) Anodes

These are used in Impressed Current Cathodic Protection (ICCP) systems. Instead of relying on a natural voltage difference, an external DC power source is used to drive current from the anode to the structure. Because of this, the anode material does not need to be more reactive. Instead, it must be extremely resistant to corrosion. This is where titanium excels. We use titanium with a Mixed Metal Oxide (MMO) coating as an inert anode. Its exceptional durability and resistance to corrosion mean it can operate for years without being consumed, even in harsh conditions like seawater or chemical processing . Anodizing titanium further enhances this by creating a protective oxide film, the opposite of a sacrificial process .

What metal makes the best anode?

Are you searching for the single "best" anode material? This pursuit can be frustrating because there is no single answer. The optimal choice is always relative to the specific electrochemical system you are using.

There is no single "best" anode. For sacrificial protection in freshwater, magnesium is best due to its high voltage. In saltwater, zinc or aluminum alloys are superior. For permanent industrial systems, MMO-coated titanium is best.

When a client asks me for the "best" anode, my first question is always, "What is your application?" The right choice balances performance, environment, lifespan, and cost. For a small boat in a lake, a magnesium anode is the best. For a large offshore oil platform, an impressed current system with titanium anodes is far superior and more cost-effective in the long run . The initial high cost of titanium can be a challenge, but its long service life and low maintenance requirements often result in lower total operational costs over time .

Best Choice for Sacrificial Protection

The "best" sacrificial anode depends on the water’s conductivity.

- Magnesium: Has the highest driving voltage of the three. This makes it the best choice for protecting structures in environments with high electrical resistivity, such as freshwater.

- Zinc and Aluminum Alloys: These have a lower driving voltage, which is actually an advantage in highly conductive seawater. It prevents them from being consumed too quickly. Aluminum alloys are often preferred for larger structures because they are lighter and have a higher electrical capacity per pound than zinc.

Best Choice for Permanent Systems

For large-scale, long-life industrial applications, the best anode is unquestionably MMO-coated titanium. My business in Baoji specializes in these advanced materials. They are used in ICCP systems where reliability and longevity are critical. While the initial investment is higher than for sacrificial anodes, the benefits are significant. They provide consistent, controllable protection for decades and are far more durable than any sacrificial anode [4][11]. This makes them the standard for pipelines, power plants, and modern marine vessels.

Which two materials are commonly used as sacrificial anodes?

Need to know the most common, go-to options for sacrificial anodes? While there are a few choices, two materials stand out for their widespread use in major industries like shipping and offshore energy.

The two most commonly used sacrificial anode materials are zinc and aluminum alloys. Zinc is a long-standing industry standard for marine applications, while aluminum alloys are increasingly popular due to their high efficiency and light weight.

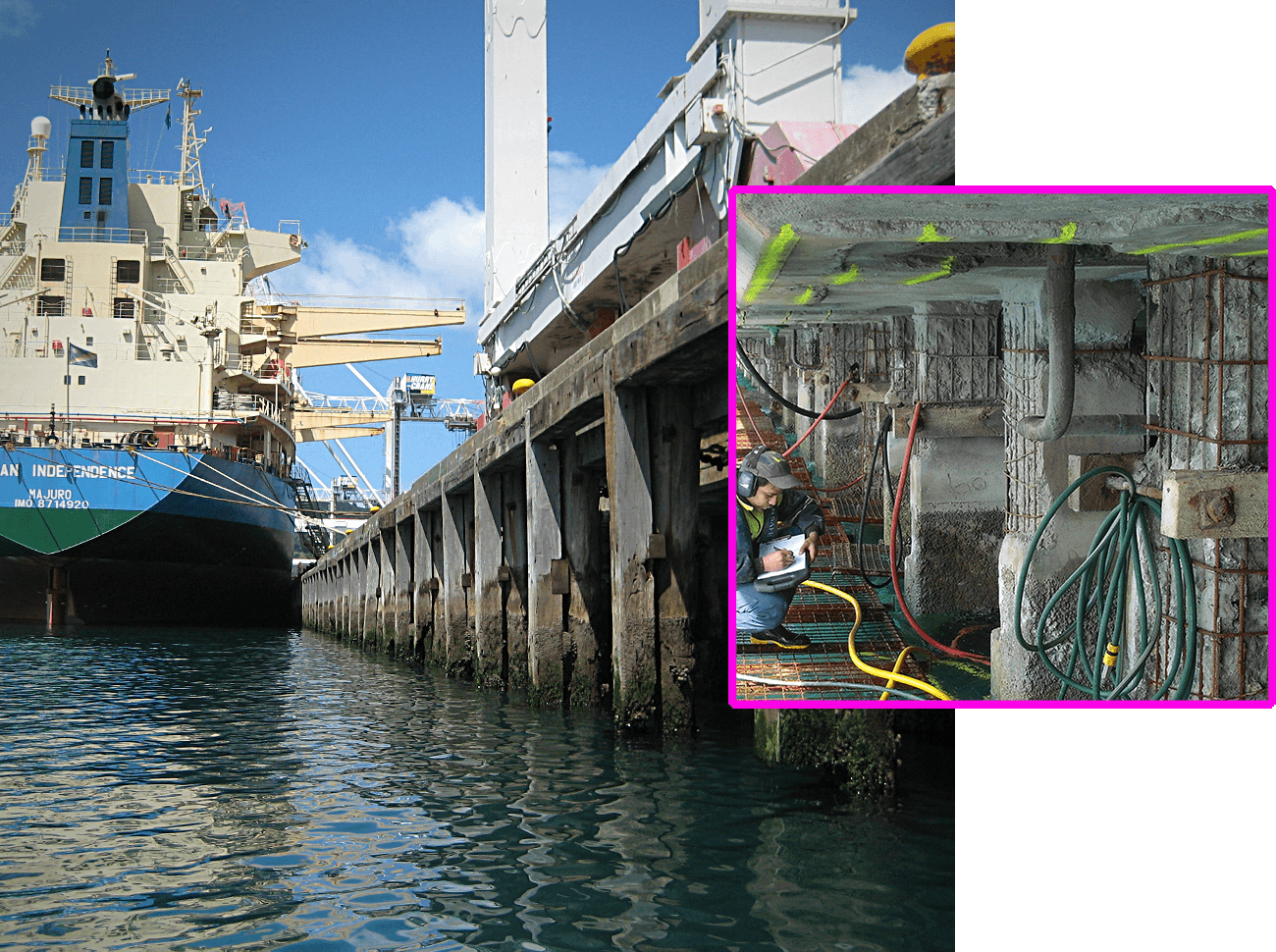

In the marine industry, protecting steel hulls, tanks, and pipelines from saltwater corrosion is a top priority. For decades, zinc and aluminum alloys have been the workhorse materials for this job. They provide effective, reliable protection without the need for complex electrical systems. While I specialize in advanced titanium solutions, I recognize that for many applications, these two sacrificial materials offer a perfect blend of performance and simplicity. The choice between them often comes down to specific operational requirements and cost considerations.

Zinc Anodes

Zinc has been the traditional choice for protecting steel in saltwater for many years. It has a very predictable corrosion rate and is not prone to passivation (becoming inactive) in seawater, which ensures it keeps working. It is very effective for ship hulls, ballast tanks, and rudders. Its reliability makes it a trusted standard in the marine industry.

Aluminum Alloy Anodes

Modern aluminum anodes are alloyed with indium and zinc to ensure they remain active and perform well. Their main advantages over zinc are a lighter weight and a higher electrical capacity. This means a smaller, lighter aluminum anode can provide the same or even more protection than a heavier zinc one. This is especially beneficial for large offshore structures and vessels where weight is a critical factor [10].

It’s important to remember that a highly corrosion-resistant metal like titanium would be the worst choice for a sacrificial anode. Because titanium is so noble, if you connected it to steel in seawater, it would actually make the steel corrode much faster [1][11]. This is why titanium is used for permanent components, not consumable ones.

Conclusion

Zinc, aluminum, and magnesium are the primary metals for sacrificial anodes. The best choice depends on the environment, with zinc and aluminum favored for saltwater and magnesium for freshwater.

3 Responses

Enjoyed studying this, very good stuff, thankyou.

thanks for your message, wish some will help you.