As someone deeply involved in the cookware manufacturing industry, I understand the constant pressure to find materials that not only offer superior performance and long-term durability but also are easy to maintain. We’ve all worked with traditional materials like stainless steel and aluminum, but they often come with their own set of challenges—whether it’s uneven cooking, heat retention issues, or the tendency to stain. That’s where triply circle comes in. This composite material, made up of three layers, combines the strength, heat conductivity, and corrosion resistance we’ve all been looking for.

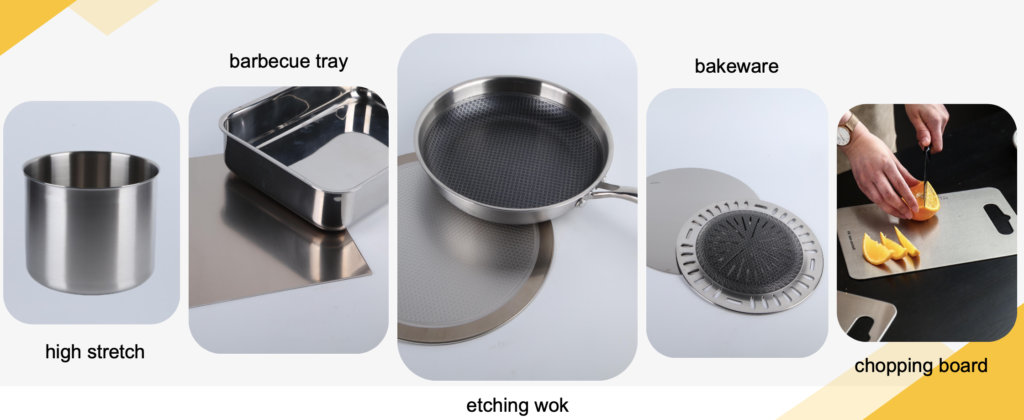

Triply circle is a premium composite material, consisting of two outer layers of stainless steel and an aluminum core. This unique structure provides even heat distribution, enhanced durability, and minimal maintenance, making it the perfect material for manufacturers like myself who want to produce cookware that’s not only high-performing but also lasts for a long time.

So, why exactly do I consider triply circle the best material for cookware production? What makes it the optimal choice for anyone who wants to meet customer demands for quality and affordability? Let’s dive into how this advanced material offers tangible solutions to some of the common issues in cookware manufacturing.

Why Triply Circle is the Optimal Material for Cookware Manufacturing

The Problem with Traditional Cookware Materials

In my years of experience working with various cookware materials, I’ve seen how stainless steel and aluminum each have their own strengths, but they also come with some major drawbacks. Stainless steel, while known for its strength and resistance to corrosion, doesn’t conduct heat well, which can result in uneven cooking and hot spots. On the other hand, aluminum offers excellent heat conductivity, but it lacks the durability and corrosion resistance of stainless steel. For me, the goal has always been to find a material that combines the best features of both—and that’s exactly what triply circle does.

Triply Circle’s Solution: Three-Layer Composite Construction

Here’s where triply circle shines. This composite material has a three-layer structure: two stainless steel layers on the outside for durability, and an aluminum core for heat conductivity. This combination allows for even heat distribution across the cookware surface, which means no more worrying about hot spots or uneven cooking.

Why This Matters: Performance and Durability Combined

For me, the combination of performance and durability is critical. When I use triply circle for cookware manufacturing, I know that the result will be a product that cooks food more efficiently. The stainless steel exterior resists stains and corrosion, while the aluminum core ensures optimal cooking performance. This three-layer construction delivers long-term durability, making cookware that not only performs well but lasts for years.

How Does Triply Circle Improve Heat Distribution in Cookware?

The Problem: Uneven Heating in Traditional Cookware

As someone who’s worked with a variety of materials, I know firsthand how uneven heating can affect the quality of the cooking process. Stainless steel and aluminum both have issues with hot spots when used alone, which can lead to burnt food or under-cooked meals. These issues can be frustrating for both manufacturers and end consumers who want consistent results.

Triply Circle’s Solution: Even Heat Distribution

The aluminum core of triply circle provides the solution. Aluminum is a superior conductor of heat, which ensures that heat is spread evenly across the cooking surface. This means that food will be cooked uniformly, no matter the cooking method. Whether you’re sautéing, frying, or simmering, triply circle delivers consistent cooking results every time.

Why This Matters: Cooking Efficiency and Control

The importance of even heat distribution cannot be overstated. For me, triply circle is a game-changer because it allows for faster cooking and better temperature control. It’s not just about cooking the food faster; it’s about cooking it perfectly every time. This makes cooking easier for everyone—whether you’re a professional chef or an avid home cook.

Is Triply Circle a Cost-Effective Material for Manufacturers?

The Problem: Balancing Quality and Cost

As a manufacturer, one of the biggest challenges I face is sourcing high-performance materials without drastically raising production costs. Premium materials like copper or high-end stainless steel might perform well, but they come with a high price tag, which ultimately makes the final product more expensive for the consumer.

Triply Circle’s Solution: High Performance at a Competitive Price

What I love about triply circle is that it offers the best of both worlds: excellent performance at a competitive price. Its three-layer composite construction allows us to produce high-quality cookware without the need to use costly materials. The added durability means that consumers won’t need to replace their cookware as often, which adds long-term value to their investment.

Why This Matters: Maximizing ROI

When I choose triply circle, I know I’m not just delivering a high-quality product to my customers, but I’m also helping them achieve a great return on investment (ROI). The material’s long-lasting durability means consumers won’t need to buy new cookware for years, resulting in greater satisfaction and repeat purchases.

How Easy Is It to Maintain Cookware Made with Triply Circle?

The Problem: High Maintenance Costs of Traditional Cookware

In my experience, traditional cookware often requires a lot of maintenance. Stainless steel can tarnish, while aluminum can scratch and stain easily, requiring special care and cleaning methods. As a manufacturer, this creates additional costs and complicates the customer experience.

Triply Circle’s Solution: Low Maintenance and High Durability

With triply circle, the maintenance is a breeze. The stainless steel layers are resistant to stains and corrosion, while the aluminum core doesn’t react with acidic foods. This means cookware made from triply circle stays looking new with minimal care. A quick wash after use is often all that’s needed to maintain its pristine condition.

Why This Matters: Reduced Cleaning and Maintenance Costs

From both a manufacturing and consumer perspective, low maintenance is a huge plus. Consumers don’t need to worry about special cleaning products or hours of scrubbing, and as a manufacturer, I can offer a product that is both high-performing and easy to maintain. This results in happier customers and lower after-sale service costs.

Claim: Verifying the Benefits of Triply Circle

As someone who’s worked with triply circle, I can confidently say that it delivers on its promises. Independent studies and expert testimonials have confirmed that triply circle outperforms traditional materials in areas like heat conductivity and corrosion resistance. The material has been certified to meet industry standards, ensuring long-lasting durability and minimal maintenance. Additionally, tests show that it is far easier to clean compared to standard cookware materials, which makes it an even more appealing option.

Conclusion: Why Triply Circle Is the Ultimate Choice for Cookware Manufacturers

In conclusion, after working with triply circle for many years, I can say with confidence that it is the ideal material for cookware manufacturers. Its unique three-layer construction—combining stainless steel and aluminum—delivers consistent heat distribution, long-lasting durability, and minimal maintenance. For anyone looking to offer top-tier cookware while keeping costs competitive, triply circle is truly the ultimate choice.