Introduction: The Importance of Specifications in TC4 Titanium Tubes

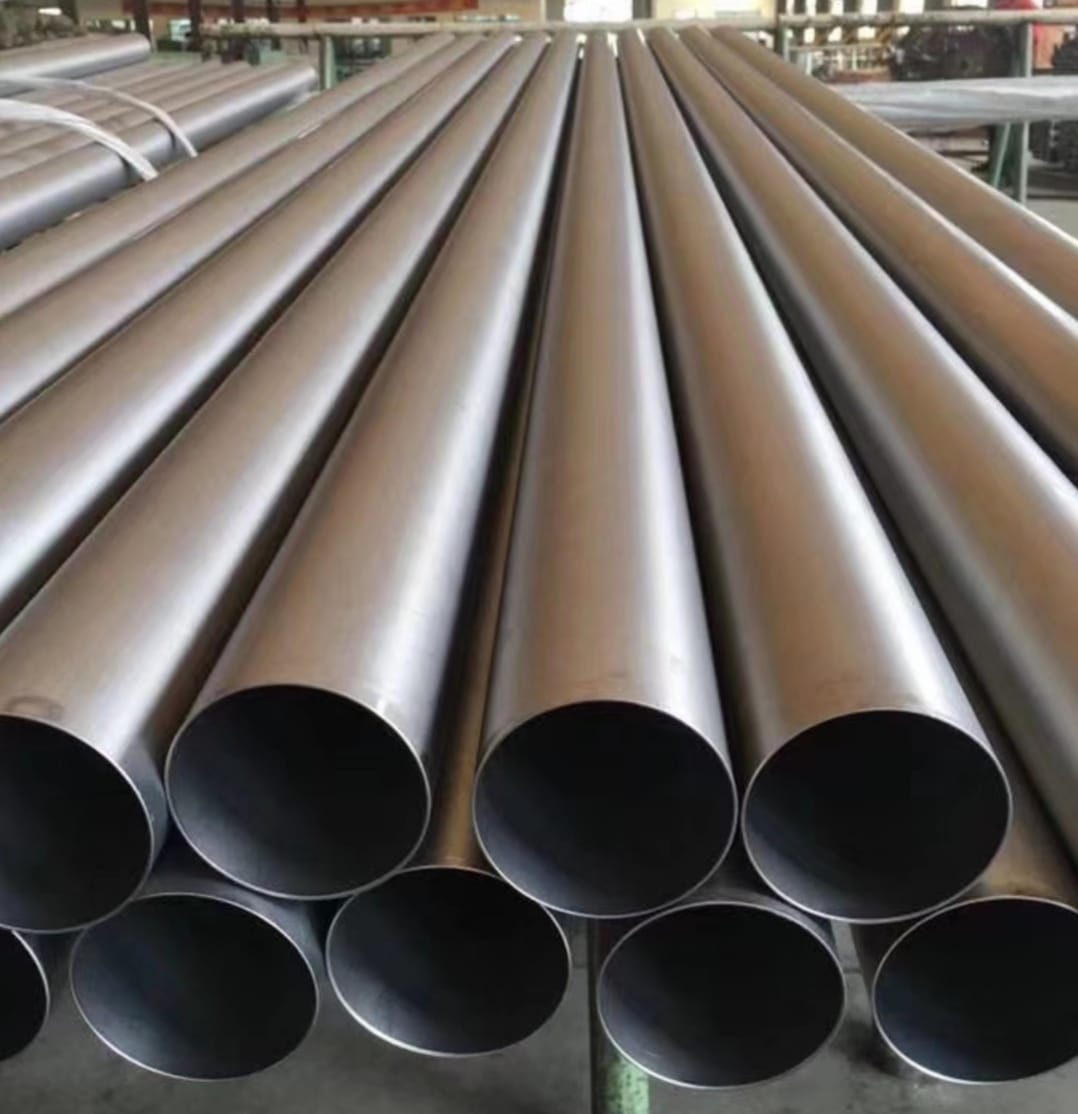

TC4 titanium tubes, also known as Ti-6Al-4V tubes, are widely used in industries that demand precision and performance, such as aerospace, medical, and energy sectors. Their dimensions, including diameter and wall thickness, are critical to meeting the requirements of specific applications. So, what are the typical diameter and wall thickness ranges for TC4 titanium tubes?

The typical diameter range for TC4 titanium tubes is 6 mm to 300 mm, with wall thicknesses ranging from 0.5 mm to 50 mm, depending on the application and manufacturing process.

Let’s explore these specifications in greater detail and how they align with industry needs.

How Does the Diameter Range Cater to Industry Requirements?

The outer diameter of TC4 titanium tubes varies depending on their intended use and the manufacturing process employed.

Key ranges:

• Small-Diameter Tubes: 6 mm to 25 mm, often used in medical devices, instrumentation, and heat exchangers.

• Medium-Diameter Tubes: 25 mm to 100 mm, suitable for aerospace hydraulic systems and automotive components.

• Large-Diameter Tubes: 100 mm to 300 mm, used in structural applications, energy systems, and industrial piping.

This versatility in diameter makes TC4 titanium tubes suitable for diverse applications across multiple sectors.

What Is the Typical Wall Thickness Range for TC4 Titanium Tubes?

The wall thickness of TC4 titanium tubes is equally critical, as it determines their strength, weight, and suitability for specific applications.

Key ranges:

• Thin-Walled Tubes: 0.5 mm to 2 mm, ideal for lightweight applications like medical implants and aerospace components.

• Standard-Walled Tubes: 2 mm to 10 mm, commonly used in industrial piping, heat exchangers, and automotive systems.

• Thick-Walled Tubes: 10 mm to 50 mm, designed for high-pressure and structural applications, such as energy systems and marine environments.

These ranges ensure TC4 titanium tubes can handle varying demands, from precise surgical applications to heavy-duty industrial uses.

How Do Dimensions Affect Performance?

The dimensions of TC4 titanium tubes directly influence their mechanical properties and functionality.

Key considerations:

• Strength and Durability: Thicker walls enhance load-bearing capacity and resistance to deformation under pressure.

• Weight Efficiency: Thinner walls reduce overall weight, improving efficiency in aerospace and transportation applications.

• Fluid Dynamics: Smaller diameters and thinner walls optimize flow rates and reduce resistance in fluid transport systems.

Selecting the right combination of diameter and wall thickness is essential to optimize performance for specific requirements.

How Are Dimensions Tailored for Specific Applications?

Manufacturers customize the dimensions of TC4 titanium tubes to meet the unique requirements of different industries.

Key examples:

• Aerospace: Thin-walled, small-diameter tubes for lightweight hydraulic systems and structural supports.

• Medical: Small-diameter tubes with precise tolerances for implants and surgical instruments.

• Energy: Thick-walled, large-diameter tubes for high-pressure piping in power plants and offshore systems.

This adaptability allows TC4 titanium tubes to excel in the most demanding environments.

How Do Manufacturing Processes Influence Dimensions?

The processes used to produce TC4 titanium tubes determine the achievable ranges for diameter and wall thickness.

Key influences:

• Extrusion: Produces medium to large diameters with uniform wall thickness.

• Cold Rolling: Refines dimensions for smaller diameters and thinner walls, enhancing precision.

• Near-Net Shape Forging: Reduces material waste while achieving complex geometries and customized sizes.

Understanding how manufacturing impacts tube dimensions helps ensure efficient production and high-quality results.

Claim: Why Accurate Dimensions Are Critical for TC4 Titanium Tubes

The typical diameter and wall thickness ranges for TC4 titanium tubes, from 6 mm to 300 mm in diameter and 0.5 mm to 50 mm in thickness, ensure that these components meet the diverse demands of high-performance applications.

Conclusion: Precision Dimensions for Maximum Performance

The wide range of diameters and wall thicknesses available for TC4 titanium tubes showcases their versatility and reliability in industries that require precision and strength. This flexibility allows them to meet the exacting demands of applications, from medical devices to aerospace and energy systems, ensuring their continued relevance in advanced engineering challenges.