Confused by industrial terms like "titanium anode"? Technical jargon can be a real barrier to understanding. I’ll explain titanium anodes simply, drawing on my experience from China’s "Titanium Valley."

A titanium anode is a highly durable electrode. It has a titanium base coated with special metal oxides. It’s widely used in processes like water treatment and electroplating due to its excellent corrosion resistance and long life.

You now know the basic definition. But why are these components so important in various industries? Coming from Baoji—China’s renowned “Titanium Valley”, I’ve seen firsthand how titanium evolves from raw sponge to high-performance industrial products. With a complete processing chain and world-class manufacturing capabilities, our region produces top-quality titanium anodes trusted worldwide. Let’s explore further what makes them special.

What is the purpose of the anode?

Wondering why anodes are even needed in the first place? Their specific function can seem mysterious. Anodes are actually vital for many electrochemical reactions to occur correctly and efficiently.

The main purpose of an anode is to facilitate an electrochemical reaction. It serves as the positive electrode where oxidation occurs. This process releases electrons crucial for applications like plating or electrolysis.

Anodes play a fundamental role in any electrochemical cell. Think of it like a battery, which has two electrodes: an anode and a cathode. In these systems, the anode is where an oxidation reaction happens. This means the anode material, or a substance in contact with it, loses electrons. These electrons then flow through an external circuit to the cathode, where a reduction reaction occurs (gaining electrons). This controlled flow of electrons is the foundation for many important industrial processes. For instance, in electroplating, metal ions in a solution gain these electrons at the cathode and deposit as a thin, protective, or decorative coating. The anode material itself might dissolve to supply these ions (this is a sacrificial anode), or it might simply help the reaction by providing a durable, conductive surface without being consumed (this is an inert or dimensionally stable anode, like many titanium anodes). My clients across different countries often need anodes for very specific reactions, and choosing the right anode material and coating is absolutely key for process efficiency and product quality.

Anode’s Role in Different Processes

| Process Type | Anode’s Primary Function | Example Application |

|---|---|---|

| Electroplating | Provides electrons, may dissolve to supply metal ions | Coating jewelry or industrial parts |

| Water Electrolysis | Facilitates oxygen evolution (splitting water) | Producing high-purity hydrogen and oxygen |

| Cathodic Protection | Sacrifices itself to protect another metal | Protecting ship hulls, pipelines, water heaters |

| Chlor-Alkali Industry | Facilitates chlorine gas evolution | Producing chlorine and caustic soda |

| Electrowinning/Refining | Drives metal ions out of solution onto cathodes | Extracting or purifying metals like copper |

This variety shows just how essential a well-designed anode is across a spectrum of applications. The anode isn’t just a piece of metal; it’s an active participant in chemical transformation.

Do titanium anode rods work?

Heard about titanium anode rods but unsure if they are truly effective? You might be doubting if they live up to the claims of long life and superior protection. Yes, they work exceptionally well.

Yes, titanium anode rods work very effectively. Their superior corrosion resistance and stable performance mean they offer long-lasting protection and efficiency in applications like water heaters or demanding cathodic protection systems.

[ ]

]

Titanium anode rods, especially those coated with Mixed Metal Oxides (MMO), are highly effective and a significant step up from traditional anode materials in many situations. I’ve seen their success firsthand in my work here in Baoji, supplying them to various industries. Their primary advantage is their incredible resistance to corrosion, even in very aggressive chemical environments or different types of water. Unlike traditional sacrificial anodes, such as magnesium or aluminum rods found in water heaters, which are designed to corrode and deplete over time, MMO-coated titanium anodes are often ‘inert’ or ‘dimensionally stable’. This means they facilitate the necessary electrochemical reaction (like driving a protective current or enabling an electrolytic process) without significantly degrading themselves. The MMO coating is the true workhorse, providing the catalytically active surface for the desired reaction (like oxygen evolution in some water treatment processes, or chlorine evolution in brine electrolysis), while the titanium substrate offers excellent structural integrity, good conductivity, and that crucial corrosion resistance. This inherent longevity translates directly to lower maintenance costs, less downtime for replacement, and more consistent, reliable performance over a much longer period. Many of our clients switch to titanium anodes for critical applications where the frequent replacement of other anode types would be impractical, too costly, or would compromise process stability. They really do deliver on their promise of durability and efficiency.

What is the best material for an anode?

So many different materials can be used as anodes! It can be confusing to know which one is truly the best choice. The answer is, it depends on the job, but titanium often stands out for demanding tasks.

The "best" anode material truly depends on the specific application and its chemical environment. However, for superior corrosion resistance, longevity, and efficiency in harsh conditions, coated titanium is often superior to materials like graphite, lead, or even other metals.

There isn’t one single "best" material for all anode applications because factors like the specific electrochemical process, the chemical environment (e.g., acidity, presence of chlorides), required current density, and overall cost-effectiveness play a huge role. However, when we look at performance characteristics in demanding industrial situations, titanium, especially when coated with a carefully selected layer of precious metal oxides (forming what’s known as a Mixed Metal Oxide or MMO anode), frequently comes out on top. I’ve worked with clients who initially used materials like graphite or lead alloys for their anodes, often to save on upfront costs. However, they often found that the shorter operational lifespan, higher consumption rates (meaning the anode itself wears away quickly), lower efficiency, and sometimes the potential for process contamination led to greater long-term operational expenses and frequent maintenance headaches. Switching to titanium anodes, despite a higher initial purchase price, often resulted in better overall economy and process stability. This is due to their exceptional durability, stable dimensions over time, and higher electrical efficiency. The ability to customize the MMO coating on the titanium substrate for specific reactions – for example, using Iridium Oxide (IrO₂) based coatings for oxygen evolution reactions or Ruthenium Oxide (RuO₂) based coatings for chlorine evolution – further enhances titanium’s suitability across a wide range of specialized applications.

Comparing Common Anode Materials

| Material | Key Advantages | Key Disadvantages | Typical Use Examples |

|---|---|---|---|

| Titanium (MMO Coated) | Excellent corrosion resistance, long life, stable, efficient | Higher initial cost compared to some traditional materials | Chlor-alkali, water treatment, electroplating, cathodic protection |

| Graphite | Relatively low cost, good electrical conductivity | Brittle, consumed during operation, lower current density limits | Older electrowinning, some electrolysis processes |

| Lead & Lead Alloys | Inexpensive | Environmental concerns (lead), can form passive insulating layers | Some electrowinning (e.g., zinc), chromium plating |

| Platinum (Platinized Ti) | Excellent catalyst, very stable, high efficiency | Very high cost, though platinizing titanium reduces this | Lab use, specialized electroplating, high-purity processes |

| Magnetite | Relatively stable in some specific solutions | Brittle, lower conductivity than metals, can be passive | Some chlorate production, niche applications |

Ultimately, the "best" choice balances performance with economics for a given industrial task.

What is the best type of anode for a water heater?

Is your water heater anode due for a replacement, or are you installing a new one? You might be wondering what the best option is for ensuring longevity and protecting your tank. Titanium anodes are increasingly popular for very good reasons.

For water heaters, powered titanium anodes (often MMO coated) are an excellent choice. They offer a very long lifespan and consistent protection, especially in aggressive or soft water conditions where magnesium or aluminum rods deplete quickly.

When it comes to protecting the inside of your water heater tank from corrosion, the anode rod plays a absolutely crucial role. Traditionally, most water heaters come equipped with sacrificial anode rods made of either magnesium or aluminum. These work by corroding preferentially to the steel tank – they "sacrifice" themselves. However, these sacrificial rods have a finite lifespan, typically lasting a few years depending on water quality, and they need regular inspection and replacement to continue protecting the tank. This is where titanium anodes offer a significant upgrade, particularly powered titanium anodes. These systems operate on a different principle called Impressed Current Cathodic Protection (ICCP). Instead of sacrificing themselves, a non-consumable MMO-coated titanium rod is used, and a small, controlled electrical current is passed from an external power supply, through the titanium anode, into the water, and onto the tank wall. This makes the entire inner surface of the tank a cathode, effectively preventing it from rusting.

Water Heater Anode Options: A Quick Comparison

| Anode Type | Protection Mechanism | Typical Lifespan | Best Suited For | Key Considerations |

|---|---|---|---|---|

| Magnesium | Sacrificial | 1-5 years | Standard water conditions, moderately hard water | Depletes, can produce hydrogen gas/sulfur odor in some water |

| Aluminum (with Zinc traces) | Sacrificial | 2-7 years | Hard water, helps reduce sulfur odor vs. magnesium | Depletes, some historical health concerns about aluminum |

| Powered Titanium (MMO) | Impressed Current (ICCP) | 10-20+ years | All water types, especially soft or aggressive water | Higher initial cost, requires a continuous power source |

Many of my clients who manage large residential or commercial properties with numerous water heaters, or even individual homeowners located in areas with very corrosive (soft) water or problematic well water, have found that the long-term reliability and minimal maintenance of powered titanium anodes make them the most cost-effective solution over the life of the water heater. It’s often a "set it and forget it" type of solution for comprehensive tank protection, eliminating the guesswork of when to replace sacrificial rods.

Do anode rods really work?

Are you skeptical about whether anode rods actually protect your equipment like water heaters? Do they truly prevent rust and extend the lifespan of metal structures? Yes, the science behind them is sound and well-proven.

Yes, anode rods absolutely work. They use a fundamental principle called cathodic protection, either by sacrificing themselves or, with powered anodes, by creating an electrochemical barrier that prevents corrosion of the protected metal structure.

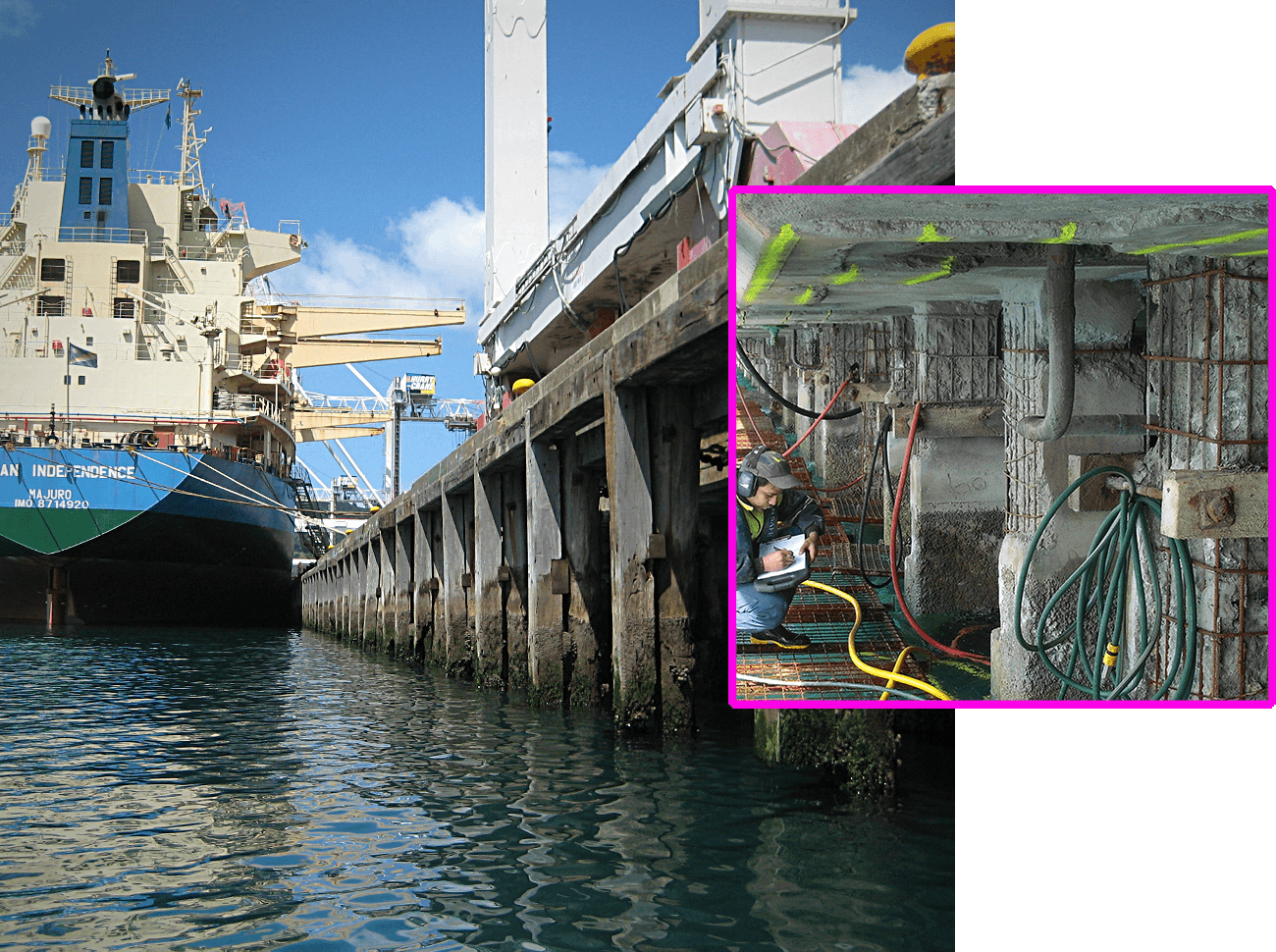

Anode rods are not a gimmick or a marketing trick; their effectiveness is based on well-established electrochemical principles that have been utilized for decades to protect a vast range of metallic structures. The most common type found in residential water heaters, the sacrificial anode rod (typically made of magnesium or aluminum), works because of differences in electrochemical potential between dissimilar metals when they are in contact through an electrolyte (like water). The anode rod is intentionally made of a more ‘active’ (less noble) metal than the steel tank it’s designed to protect. When immersed in water, this more active anode metal corrodes preferentially, ‘sacrificing’ itself by releasing electrons. These electrons flow to the steel tank, making it a cathode and thereby preventing it from rusting. I’ve seen countless examples in my field where a neglected sacrificial anode rod was found to be completely consumed, and shortly after, the tank it was supposed to protect started showing signs of corrosion or failure. Powered titanium anodes, as discussed, take this protection a step further by using an external power source to impress a current onto the titanium anode, which then makes the entire tank a cathode. This actively suppresses corrosion. So, whether the mechanism is sacrificial or by impressed current, the fundamental concept is to force the metal structure you want to protect to become the cathode in an electrochemical cell. It’s a highly reliable and widely applied method used not just in water heaters, but also for protecting underground pipelines, ship hulls, offshore oil rigs, and bridges. The key is always choosing the right anode material for the specific environment and ensuring it’s properly installed and, in the case of sacrificial anodes, monitored and replaced when depleted. My experience working with high-quality materials like the titanium we produce in Baoji continually reinforces that when correctly applied, these anode systems are incredibly effective.

Conclusion

Titanium anodes offer superior corrosion resistance and longevity. They are vital for efficient electrochemical processes across many industries, from water treatment to electroplating, ensuring reliable and lasting performance.

3 Responses

vardenafil powder factories levitra migliore levitra indications