Using robust titanium anodes without care can still shorten their life. Worried about damaging components or getting poor results? Understanding key precautions ensures longevity and peak performance.

To maximize titanium anode performance and lifespan, avoid contact with organic solvents, operate within recommended current density (typically under 750 A/m²), maintain a clean electrolyte free of impurities like fluorides, prevent dry operation, and store in a clean, dry environment.

After years of working with titanium anodes in electrochemical applications, I’ve learned that even the most durable materials need proper handling to maximize performance. Titanium anodes are highly stable—but they’re not invincible. Understanding the right usage practices helps extend their lifespan and ensure consistent results. With my background in titanium product sales and deep connections to China’s titanium manufacturing hub in Baoji, I’ve helped many clients optimize their processes by integrating high-quality, well-maintained titanium anodes. A little attention to detail goes a long way.

What are the safety precautions for titanium?

Titanium is known for strength, but are there hidden safety issues? You might have concerns about handling titanium in industrial or daily settings. It’s good to know that titanium is generally non-toxic and biocompatible, ensuring safe use in many applications.

Titanium is generally very safe, being non-toxic and biocompatible, making it ideal for medical implants and everyday products. However, due to its hardness, machining titanium requires specialized equipment and techniques .

Titanium itself is renowned for its safety profile, especially concerning toxicity and biocompatibility . This is a key reason why it’s extensively used in medical implants like joint replacements and dental fixtures, as it doesn’t typically cause adverse reactions within the human body. It’s also considered safe for products that come into contact with skin, such as jewelry and eyeglass frames . In industrial settings like chemical processing or petroleum industries, its non-toxic nature ensures product purity when handling sensitive chemicals.

However, the main "safety precautions" for titanium often relate more to its processing and handling rather than inherent material toxicity.

Handling and Processing Considerations

One significant aspect is its machining difficulty. Titanium and its alloys are hard materials, which means they require specialized tools, coolants, and techniques to cut, drill, or shape. Attempting to machine titanium with standard equipment can lead to rapid tool wear, overheating, and potentially unsafe conditions due to flying debris or tool breakage. This hardness also contributes to higher manufacturing costs.

Another point is during welding. While titanium is weldable, it requires a very clean environment and often inert gas shielding (like argon) to prevent contamination from oxygen, nitrogen, and hydrogen at high temperatures, which can embrittle the weld.

For titanium anodes specifically, as mentioned in my initial insights, while the titanium substrate is safe, the metal oxide coatings (like IrO₂, RuO₂) should be handled with care. Avoid creating dust if a coating is damaged, and follow standard industrial hygiene. Also, avoid contact with organic solvents or grease, as these can affect coating activity. Maintain a clean electrolyte because impurities like fluorides can corrode the coating.

Can titanium be used as an anode?

Are you unsure if titanium is suitable for demanding anode applications? Perhaps you’re doubting its electrochemical properties or long-term durability. Let me assure you, titanium is an excellent choice, especially when appropriately coated.

Yes, titanium is widely and effectively used as an anode, particularly when coated with specialized metal oxides . Its inherent corrosion resistance and ability to support various catalytic coatings make it ideal for many electrochemical processes.

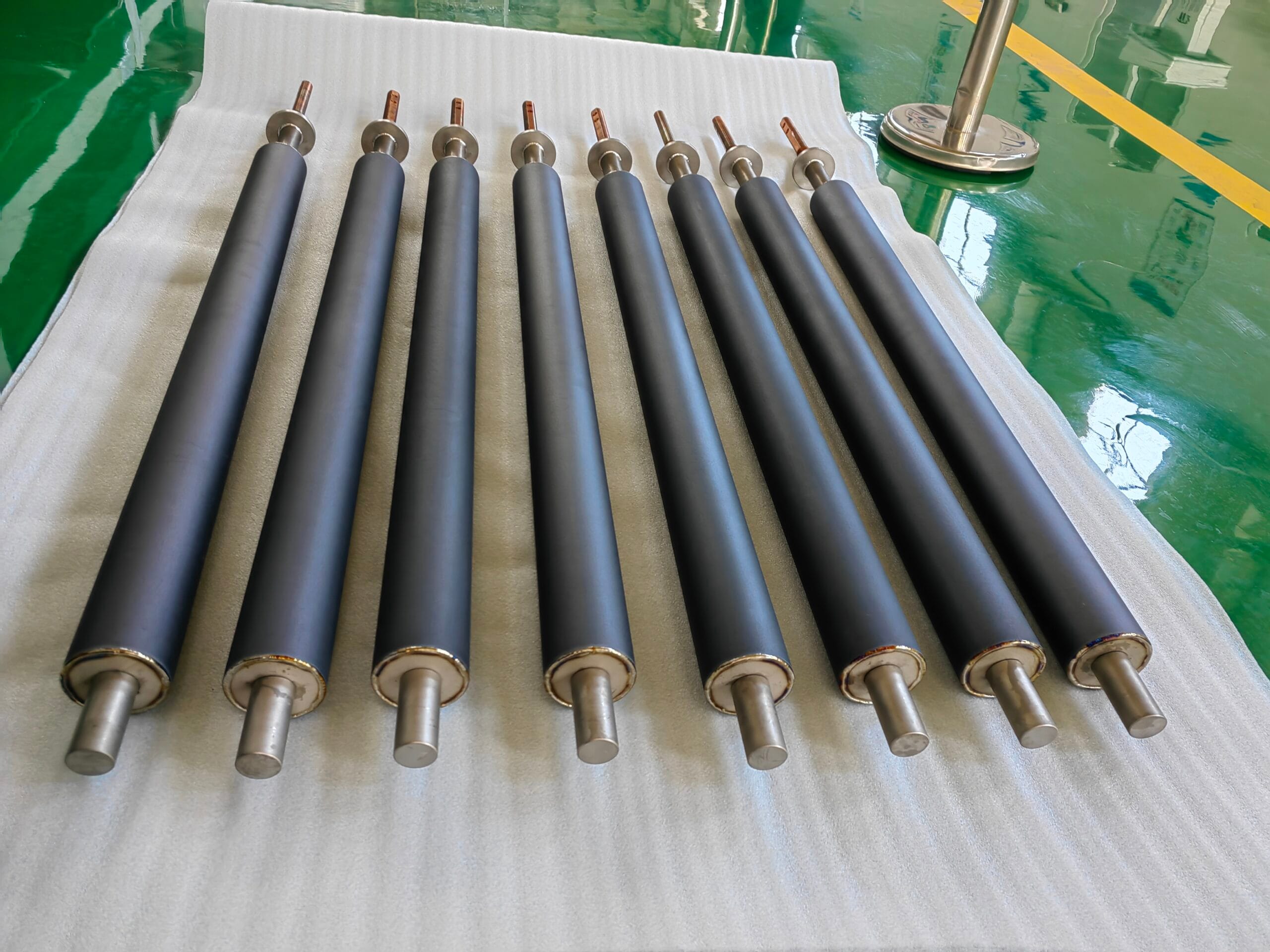

Absolutely, titanium is not only usable but is often a preferred material for anodes in a wide array of electrochemical applications. While pure titanium can act as an anode, its true strength in this role comes when it serves as a substrate for various catalytic coatings, typically precious metal oxides (like Iridium Oxide – IrO₂, Ruthenium Oxide – RuO₂) or Mixed Metal Oxides (MMO). The insight I provided emphasizes this: "A titanium anode is essentially a titanium substrate coated with precious metal oxides."

My experience, rooted in Baoji, China’s “Titanium Valley,” has shown me the extensive development and application of these coated titanium anodes for uses in electroplating, water treatment, and chlor-alkali production.

Why Titanium Excels as an Anode Substrate

- Exceptional Corrosion Resistance: Titanium forms a stable, passive oxide layer (TiO₂) on its surface when exposed to oxygen or moisture. This layer protects the underlying metal from aggressive electrolytes, ensuring the anode’s structural integrity over long periods. This is particularly important in harsh environments.

- Good Electrical Conductivity: While not as conductive as copper, titanium’s conductivity is sufficient for most anode applications, especially when considering its other benefits.

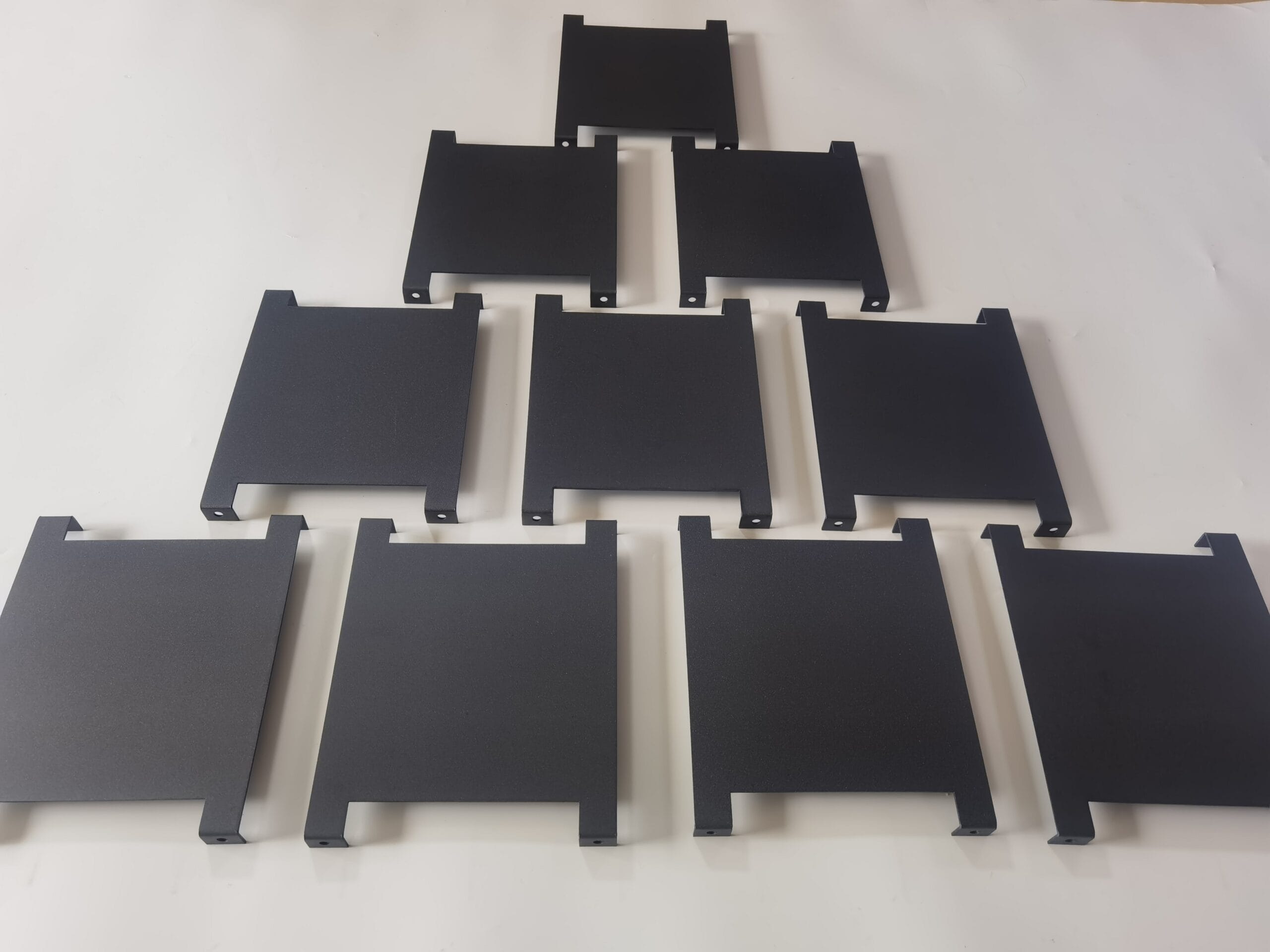

- Mechanical Strength and Durability: Titanium anodes can be fabricated into various shapes (plates, meshes, tubes, rods) and maintain their form and function even under demanding operational conditions, contributing to their durability.

- Ability to Support Catalytic Coatings: The surface of titanium can be prepared to create a good bond with various electrocatalytic coatings. These coatings drive the desired electrochemical reactions efficiently. Anodizing can also be applied to titanium to form an oxide layer, enhancing certain properties or serving as a base for further coatings.

Do titanium anode rods work?

Are you skeptical about the real-world effectiveness of titanium anode rods? You might be wondering if they truly offer better protection or a longer lifespan compared to traditional options. From my experience, they are highly effective.

Yes, titanium anode rods, particularly those coated with Mixed Metal Oxides (MMO), are highly effective. They provide superior corrosion resistance and a significantly long service life in applications like cathodic protection for water heaters or demanding industrial equipment.

Titanium anode rods, especially those coated with Mixed Metal Oxides (MMO), are not only functional but often represent a significant upgrade in performance and longevity compared to traditional anode materials in many applications. My work supplying these components from Baoji has consistently demonstrated their effectiveness in various sectors.

Their primary advantage lies in the combination of titanium’s inherent properties and the catalytic nature of the MMO coating. As highlighted in my insights, these anodes are valued for their exceptional corrosion resistance, conductivity, and long service life.

Effectiveness in Key Applications

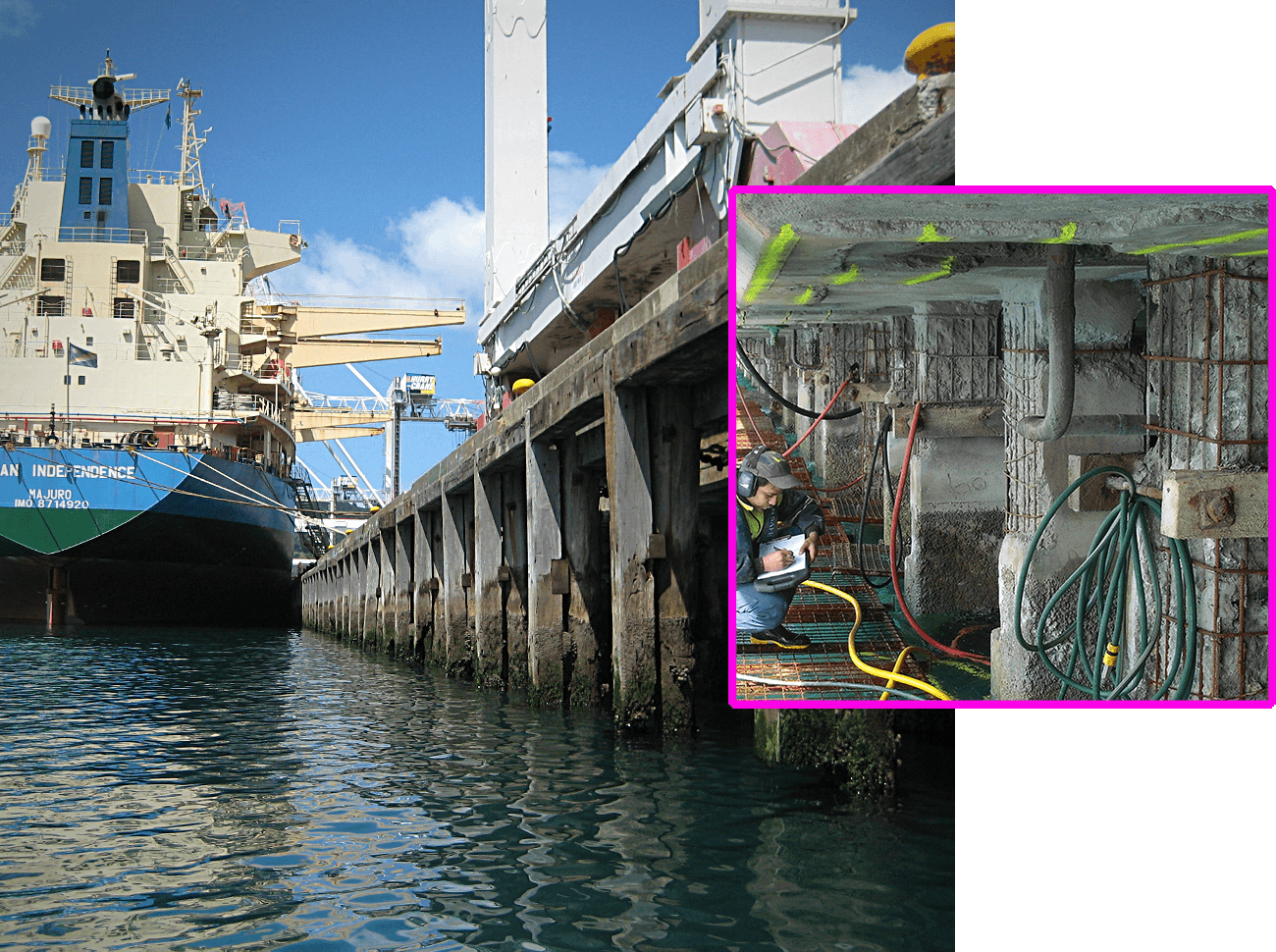

- Cathodic Protection: This is a major area where titanium anode rods excel. In systems like water heaters, underground pipelines, or marine structures, traditional sacrificial anodes (magnesium, aluminum) corrode and deplete. MMO-coated titanium anodes, when used in an impressed current cathodic protection (ICCP) system, do not significantly consume themselves. Instead, they serve as a durable, inert pathway for the protective current. This results in more consistent, longer-lasting protection.

- Electrolytic Processes: In processes like brine electrolysis for chlorine production or water electrolysis, titanium anodes provide a stable and efficient surface. Their dimensional stability ensures the electrode gap remains constant, crucial for process efficiency. My initial insight points to their use in chlor-alkali production.

- Durability: The exceptional corrosion resistance of titanium means these rods can withstand harsh chemical environments where other materials might fail. This leads to reduced maintenance and replacement costs, a key benefit of titanium. One of the precautions I always mention is to use them within the recommended current density, typically under 750 A/m², to ensure this durability.

Why is titanium used as anode in electrolysis of brine?

Curious why titanium is the go-to material for anodes in the harsh process of brine electrolysis? What makes it stand out against other materials in such an aggressive chemical environment? Its unique combination of corrosion resistance and support for catalytic coatings is key.

Titanium is used as an anode in brine (saltwater) electrolysis primarily due to its excellent corrosion resistance to chlorides and its capability to support specific catalytic coatings (like RuO₂) that efficiently facilitate the production of chlorine gas.

The electrolysis of brine (sodium chloride solution) to produce chlorine gas, caustic soda, and hydrogen is a massive industrial process, and the anode material is critical for efficiency and longevity. Titanium, specifically in the form of Dimensionally Stable Anodes (DSAs) – which are titanium substrates coated with metal oxides like Ruthenium Oxide (RuO₂) or a mix including Iridium Oxide (IrO₂) – has become the industry standard. My work in China’s titanium hub involves helping customers customize such anodes for high-purity chemical processing like this.

Key Reasons for Titanium’s Dominance in Brine Electrolysis

- Superior Corrosion Resistance to Chlorides: Brine solutions are highly corrosive due to chloride ions and wet chlorine gas. Titanium exhibits excellent resistance in this environment, preventing anode degradation and product contamination.

- Catalytic Activity of Coatings: The metal oxide coatings on the titanium are specifically chosen for high catalytic activity towards chlorine evolution, making the process more energy-efficient. The titanium base provides stable, conductive support.

- Dimensional Stability: Unlike older graphite anodes that eroded, coated titanium anodes maintain their shape. This ensures consistent performance and stable voltage. One of the precautions from my initial insights is not to run the anode dry, as exposure to air during operation can damage this vital oxide layer or coating.

- Lower Overpotential for Chlorine Evolution: The specialized coatings lead to less wasted energy, which is significant for the overall energy consumption of the chlor-alkali process.

- Purity of Products: Because the titanium anode (with its coating) is so stable and doesn’t significantly corrode into the electrolyte, it helps ensure the high purity of the chlorine and caustic soda produced. This aligns with titanium’s non-toxic nature and its suitability for processes involving sensitive chemicals.

These combined factors make coated titanium anodes the most economically viable and technically superior choice for modern chlor-alkali plants.

Conclusion

Proper handling of titanium anodes is essential. Adhering to vital precautions like avoiding solvents, managing current density, and ensuring clean electrolytes significantly maximizes their operational lifespan and consistent performance in critical applications.