Introduction: Why Titanium Plate and Sheet Are Essential in Modern Industry

In various industries, the choice of material can make a significant impact on performance, durability, and efficiency. Titanium plate and sheet have become essential components due to their unique blend of strength, corrosion resistance, and lightweight characteristics. But what specific advantages do titanium plates and sheets bring to the table?

Titanium plates and sheets offer exceptional durability, corrosion resistance, and versatility, making them ideal for demanding applications across industries like aerospace, medical, and marine. These characteristics provide lasting performance in critical environments where other materials might not hold up as well.

Here’s a deeper look at the key benefits of titanium plates and sheets, along with their primary applications and roles in various industries.

What Are the Key Benefits of Using Titanium Plate and Sheet?

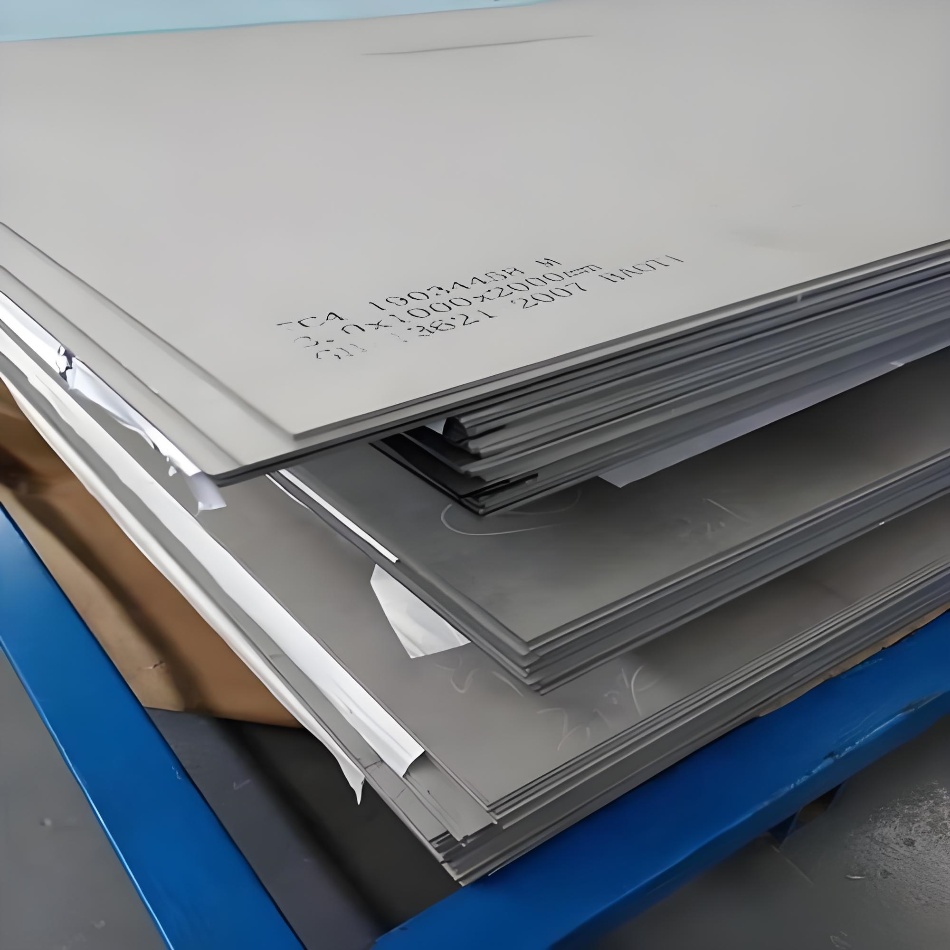

Titanium plates and sheets are known for their exceptional physical properties. Lightweight yet strong, titanium combines attributes that make it an outstanding choice for applications that require durability without the added weight of steel or other metals.

Advantages of Titanium Plate and Sheet:

• High Strength-to-Weight Ratio: Titanium provides superior strength while remaining lightweight, enhancing performance and efficiency.

• Corrosion Resistance: Titanium’s natural resistance to rust and corrosion means it can withstand extreme conditions, including marine and chemical environments.

From my experience, these qualities make titanium plates and sheets an excellent investment, as they perform reliably in harsh conditions while remaining easy to handle and transport.

Why Is Titanium’s Lightweight Design Valuable in Industry Applications?

Titanium’s low weight allows for greater flexibility and efficiency, especially in applications where minimizing load is essential. This advantage is critical in industries where weight affects performance, such as aerospace and automotive sectors.

Advantages of Lightweight Titanium:

• Improved Fuel Efficiency: Lightweight materials reduce fuel consumption in aerospace and automotive applications.

• Easier Handling and Installation: Titanium’s reduced weight simplifies installation and handling in construction or industrial settings.

For me, titanium’s lightweight structure has proven invaluable in projects requiring mobility and efficiency without compromising on strength.

How Does Titanium’s Corrosion Resistance Enhance Its Industrial Use?

One of titanium’s most beneficial properties is its resistance to corrosion, which extends the lifespan of components and reduces maintenance requirements. This makes titanium plate and sheet a smart choice for environments with high exposure to moisture, chemicals, and other corrosive elements.

Advantages of Corrosion Resistance:

• Long-Term Durability: Titanium components remain intact and functional in marine, chemical, and coastal environments, reducing replacement needs.

• Lower Maintenance Costs: With reduced risk of corrosion, titanium parts require less maintenance, saving both time and money.

In applications exposed to water, chemicals, or salt, I’ve found that titanium’s corrosion resistance makes it a reliable material that maintains its integrity over time, ensuring consistent performance.

Why Is Titanium’s Biocompatibility Important in Medical Applications?

Titanium’s biocompatibility is essential for medical applications, particularly in implants and surgical instruments, as it does not cause adverse reactions within the body. This property makes titanium sheets and plates highly valuable in the healthcare industry.

Advantages of Biocompatibility:

• Safe for Implants and Medical Devices: Titanium’s compatibility with human tissue allows it to be used in long-term implants and prosthetics.

• Enhanced Patient Comfort and Recovery: Its non-toxic nature ensures that titanium devices integrate well with the body, reducing complications.

In medical settings, titanium’s biocompatibility has been transformative, offering a safer, more comfortable option for patients and expanding the possibilities for medical device design.

How Does Titanium’s Heat Resistance Benefit High-Temperature Applications?

Titanium’s ability to maintain structural integrity at high temperatures makes it suitable for applications where other metals might weaken. This quality is critical for industries that involve high-temperature environments, such as aerospace and power generation.

Advantages of Heat Resistance:

• Suitable for Jet Engines and Power Plants: Titanium can withstand the intense heat generated in jet engines and other high-temperature systems.

• Consistent Performance Under Stress: Its resilience under thermal stress provides reliability in demanding applications.

With titanium’s heat resistance, I can trust that components will hold up under extreme temperatures, reducing risks in high-stakes environments.

Why Is Titanium Plate and Sheet Common in Aerospace and Defense?

Aerospace and defense industries require materials that combine strength, durability, and lightweight properties. Titanium meets these requirements, providing reliable performance in applications where safety and efficiency are paramount.

Advantages for Aerospace and Defense:

• Enhanced Aircraft Performance: Titanium’s lightweight properties improve fuel efficiency and maneuverability in aircraft.

• Resilience in Defense Applications: Its strength and durability make titanium ideal for armor, weaponry, and high-stress environments.

For aerospace and defense, titanium has proven indispensable, offering both safety and performance improvements that meet the rigorous demands of these sectors.

How Does the Versatility of Titanium Support Industrial Manufacturing?

Titanium’s versatility allows it to be molded, welded, and formed into various shapes, making it a flexible option for manufacturers. This adaptability enables it to meet the specific demands of each application, from large sheets for structural components to thin plates for smaller, detailed parts.

Advantages of Versatile Manufacturing:

• Supports Customization: Titanium can be tailored to precise dimensions, catering to unique project specifications.

• Compatible with Advanced Manufacturing Techniques: Its flexibility makes it suitable for modern manufacturing methods, including 3D printing and precision welding.

This versatility means that titanium can be adapted to a wide range of applications, allowing me to use it in custom solutions across different projects.

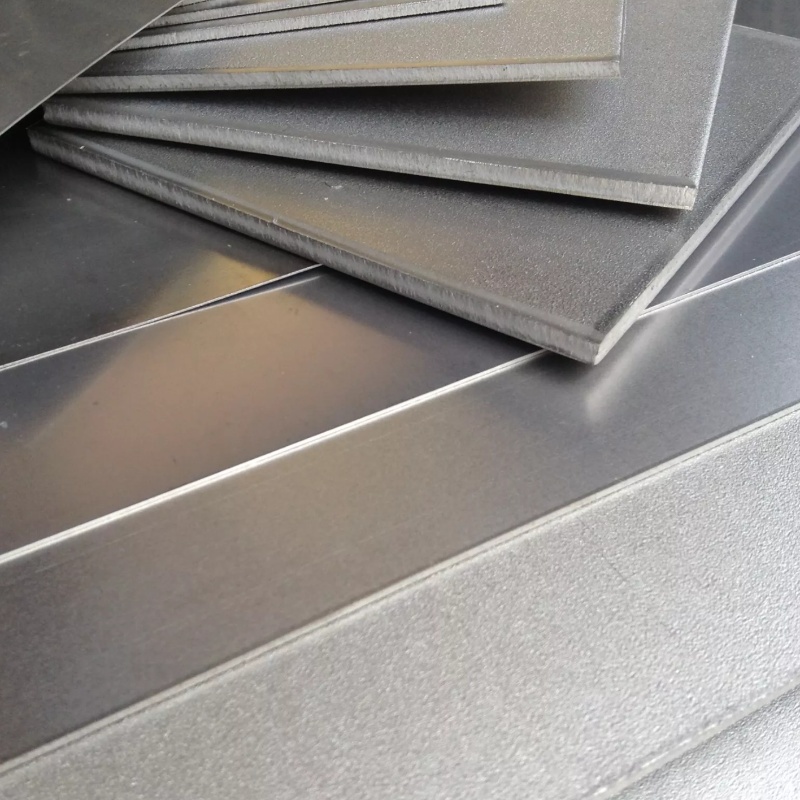

How Does Titanium’s Aesthetic Appeal Add Value in Certain Industries?

In addition to its physical properties, titanium has a sleek and attractive appearance that adds visual appeal. This quality is valuable in high-end consumer products, luxury goods, and architectural applications where appearance matters.

Advantages of Aesthetic Appeal:

• Used in Luxury Goods: Titanium’s metallic luster and corrosion resistance make it popular in jewelry and premium consumer products.

• Architectural Applications: Its aesthetic and durable qualities make it suitable for building facades, interiors, and decor.

For high-end projects, titanium’s unique look enhances the product, combining functionality with a premium appearance that appeals to consumers.

Claim: Why Titanium Plate and Sheet Are Essential for Industrial Advancement

Titanium plates and sheets offer unmatched benefits like lightweight strength, corrosion resistance, heat resilience, and biocompatibility, making them essential for various applications. These properties contribute to their role as a preferred material across industries, enhancing durability, performance, and aesthetic value.

Conclusion: Why Titanium Plate and Sheet Stand Out in Modern Industry

Titanium’s unique characteristics—lightweight strength, corrosion resistance, biocompatibility, and adaptability—make it an invaluable material in today’s industrial landscape. From aerospace to medical and beyond, titanium plate and sheet continue to set the standard for performance and longevity.

Using titanium plates and sheets has revolutionized my approach to industrial projects. With their reliability, adaptability, and resilience, they provide a long-term solution that aligns with industry demands and continues to push the boundaries of what’s possible. For any project where quality and durability are essential, titanium is a top-tier choice.