Introduction

Titanium bars and rods are versatile materials that offer exceptional properties, making them valuable across a range of industries. This article explores the unique features, diverse applications, and key benefits of titanium bars and rods, highlighting why they are a preferred choice for demanding applications.

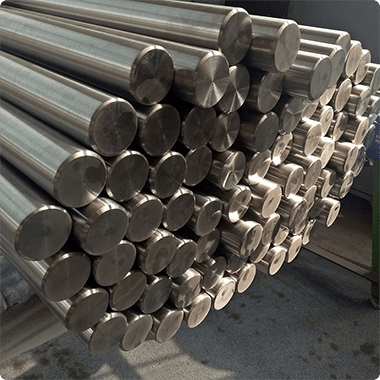

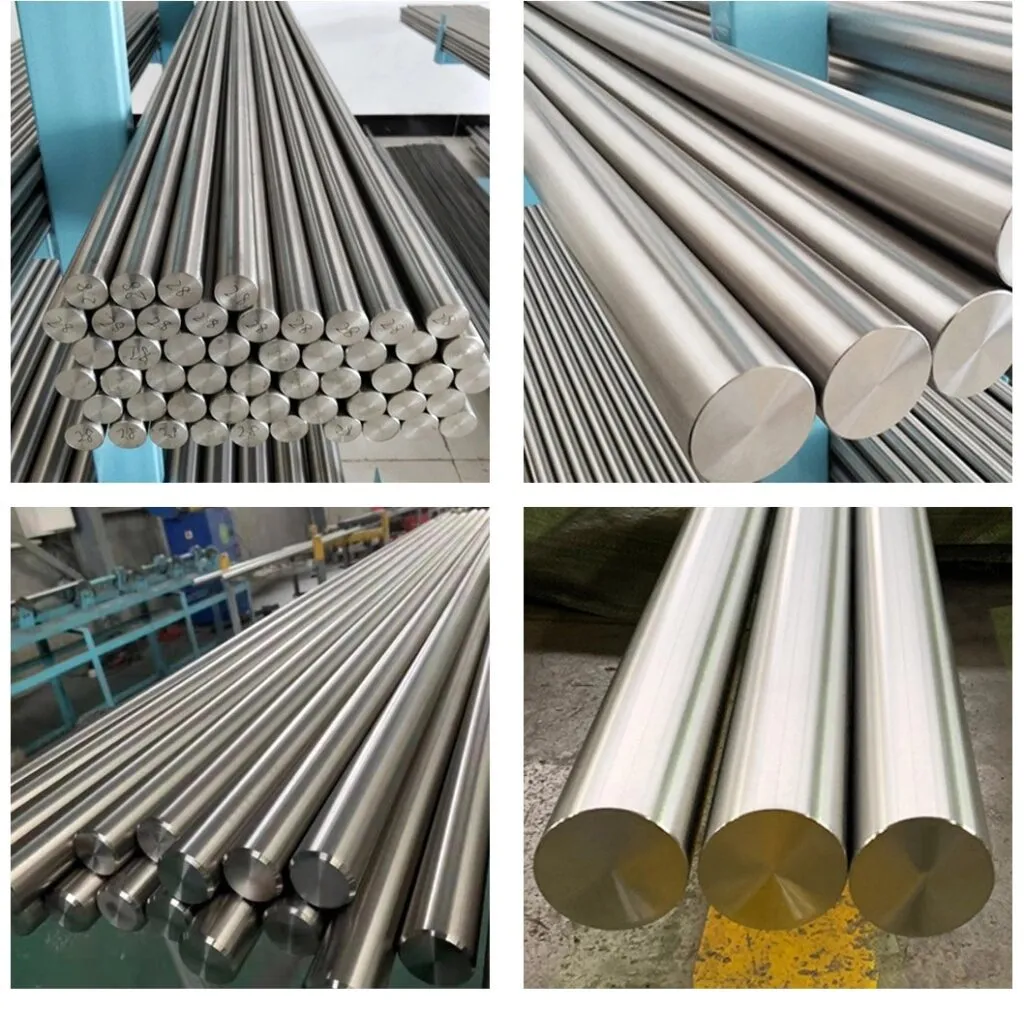

What Are Titanium Bar and Rod?

Titanium bars and rods are long, solid cylindrical forms made from titanium, available in different sizes and grades. These materials are known for their excellent strength, low density, and outstanding corrosion resistance, making them ideal for various industrial uses.

Titanium bars are typically larger in diameter and length, often used for heavy-duty applications, while titanium rods are smaller in diameter and used for precision parts and lighter applications. Both forms serve distinct purposes based on the specific requirements of the application.

The Most Commonly Used Grades of Titanium Bars and Rods

Titanium bars and rods come in various grades, each with specific properties that make them suitable for different applications. The most commonly used grades include:

- Grade 2: Known as commercially pure titanium, Grade 2 offers excellent corrosion resistance and good weldability, making it suitable for chemical processing and marine applications.

- Grade 5 (Ti-6Al-4V): This is the most widely used titanium alloy, known for its high strength and heat resistance. It is commonly used in aerospace, medical implants, and high-performance automotive components.

- Grade 7: Similar to Grade 2 but with added palladium, Grade 7 provides enhanced corrosion resistance, particularly in highly acidic environments. It is often used in chemical processing applications.

- Grade 9 (Ti-3Al-2.5V): This grade offers a balance of strength, corrosion resistance, and formability, making it ideal for aerospace tubing, marine components, and sports equipment.

Key Features of Titanium Bar and Rod

1. High Strength-to-Weight Ratio

Titanium bars and rods possess a high strength-to-weight ratio, offering strength comparable to that of steel while being much lighter. This makes them ideal for industries where strength without added weight is crucial, such as aerospace and automotive manufacturing.

2. Corrosion Resistance

Titanium’s natural resistance to corrosion, especially in harsh environments, makes it suitable for applications exposed to chemicals, seawater, or extreme conditions. This is particularly useful in industries like marine, chemical processing, and aerospace.

3. Heat Resistance

Titanium can withstand high temperatures without losing its strength or integrity, making titanium bars and rods suitable for high-temperature applications, including aerospace and industrial machinery.

4. Biocompatibility

Titanium is biocompatible and non-toxic, making it an excellent material for medical and dental applications, such as implants, surgical tools, and orthopedics.

Applications of Titanium Bar and Rod

1. Aerospace and Aviation

Titanium bars and rods are used extensively in the aerospace industry due to their combination of strength, low weight, and resistance to heat and corrosion. They are used in aircraft components, engine parts, and structural elements that require reliability and high performance.

2. Medical and Dental Applications

In the medical field, titanium’s biocompatibility makes it an ideal material for implants, such as bone screws, joint replacements, and dental implants. Titanium rods are used for orthopedic purposes due to their compatibility with the human body, ensuring safe and long-lasting results.

3. Marine Industry

Titanium rods and bars are highly resistant to seawater corrosion, making them a suitable choice for marine hardware, underwater components, and shipbuilding applications where durability is essential.

4. Chemical Processing

Titanium bars and rods are used in the chemical industry to manufacture equipment that must endure corrosive chemicals and extreme temperatures. This includes reactors, valves, and heat exchanger components that require high corrosion resistance.

5. Automotive Industry

Titanium rods are used in the automotive industry, especially in high-performance and sports vehicles, to reduce weight while maintaining strength and performance. They are used in engine components, suspension systems, and exhausts, helping improve fuel efficiency and vehicle dynamics.

Titanium Bar vs. Titanium Rod: Which to Choose?

- Application Requirements: Titanium bars are better suited for structural and load-bearing applications, while rods are ideal for precision parts and smaller components.

- Size Considerations: Bars are generally thicker and longer, whereas rods are smaller in diameter, making them suitable for more intricate work.

Who Should Use Titanium Bars and Rods?

Titanium bars and rods are ideal for manufacturers and industries requiring strong, lightweight, and corrosion-resistant materials. They are valuable in aerospace, medical, marine, chemical, and automotive industries, where reliability and performance are critical.

FAQ Section

- What Is the Difference Between Titanium Bar and Rod?

Titanium bars are larger and used for structural applications, while titanium rods are smaller and used for precision parts and lighter applications. - Why Are Titanium Bars Preferred in Aerospace Applications?

Titanium bars offer high strength, low weight, and heat resistance, making them suitable for critical aerospace components. - Is Titanium Safe for Medical Use?

Yes, titanium is biocompatible and non-toxic, making it ideal for medical implants and surgical tools. - What Are the Corrosion Resistance Properties of Titanium?

Titanium is highly resistant to corrosion, especially in seawater and harsh chemical environments. - Can Titanium Rods Be Used in Marine Applications?

Yes, titanium rods are highly resistant to seawater corrosion, making them ideal for marine hardware and underwater components. - How Does Titanium Improve Automotive Performance?

Titanium’s lightweight and strong properties help improve vehicle performance, fuel efficiency, and durability, especially in high-performance cars. - What Makes Titanium Heat Resistant?

Titanium has a high melting point and retains strength at high temperatures, making it suitable for heat-intensive applications. - Are Titanium Bars and Rods Easy to Machine?

Titanium can be challenging to machine due to its toughness, but with proper techniques and tools, it can be effectively machined into various components. - What Industries Benefit Most from Titanium Bars and Rods?

Industries such as aerospace, medical, marine, chemical processing, and automotive benefit greatly from titanium’s unique properties. - How Do Titanium Bars and Rods Compare to Other Metals?

Titanium offers superior strength-to-weight ratio, excellent corrosion resistance, and high heat resistance compared to other commonly used metals like steel and aluminum. - What Are the Most Common Grades of Titanium Bars and Rods?

The most common grades are Grade 2, Grade 5 (Ti-6Al-4V), Grade 7, and Grade 9, each with specific properties for different applications. - Which Titanium Grade Is Best for Chemical Processing Applications?

Grade 7 is ideal for chemical processing due to its enhanced corrosion resistance, particularly in highly acidic environments. - Why Is Grade 5 Titanium Commonly Used in Aerospace?

Grade 5 titanium (Ti-6Al-4V) is known for its high strength and heat resistance, making it well-suited for demanding aerospace applications. - Can Grade 2 Titanium Be Used for Marine Applications?

Yes, Grade 2 titanium is commonly used in marine applications due to its excellent corrosion resistance to seawater. - What Is the Advantage of Using Grade 9 Titanium in the Automotive Industry?

Grade 9 titanium offers a good balance of strength, corrosion resistance, and formability, making it suitable for lightweight automotive components.

Conclusion

Titanium bars and rods provide unique advantages, including high strength, low weight, corrosion resistance, and biocompatibility. Their versatility makes them suitable for a wide range of applications in industries such as aerospace, medical, marine, chemical processing, and automotive. Choosing titanium bars and rods ensures reliability, durability, and enhanced performance in demanding environments.