Titanium Products for Military Industry

Our titanium products for the military industry offer unmatched strength, lightweight durability, and corrosion resistance. Ideal for use in aircraft, armored vehicles, naval vessels, and weapon systems, titanium ensures superior performance in demanding defense applications while reducing overall weight for enhanced mobility and fuel efficiency.

Product Summary:

The advantages of titanium alloys in the military industry include:

High Strength-to-Weight Ratio: Titanium alloys provide exceptional strength while being significantly lighter than steel, improving mobility and fuel efficiency in military vehicles, aircraft, and equipment.

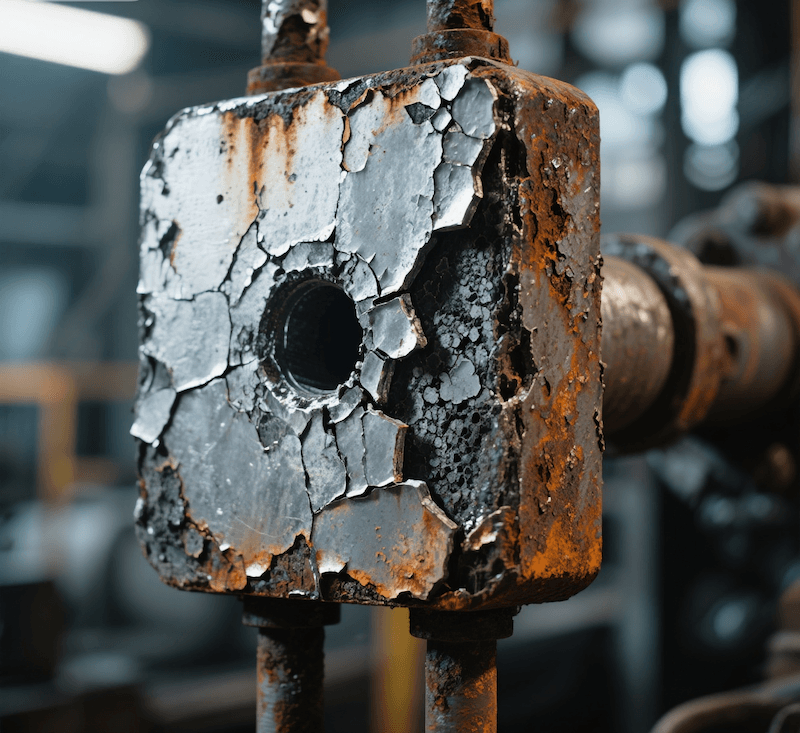

Corrosion Resistance: Titanium is highly resistant to corrosion from harsh environments, including saltwater, making it ideal for naval and marine applications.

Ballistic Protection: Titanium’s strength and durability make it effective in armor plating, offering enhanced protection for military vehicles and personnel while maintaining a lower weight than traditional materials.

Heat Resistance: Titanium alloys can withstand extreme temperatures, making them suitable for applications in high-heat environments, such as jet engines and exhaust systems.

Non-Magnetic Properties: Titanium’s non-magnetic nature makes it advantageous in stealth technology and in minimizing interference with electronic systems in defense equipment.

Durability: Titanium alloys provide long-term durability and resistance to wear and fatigue, ensuring extended service life for military hardware and reducing maintenance needs.

Military industry titanium alloys are widely applied in various critical areas, including:

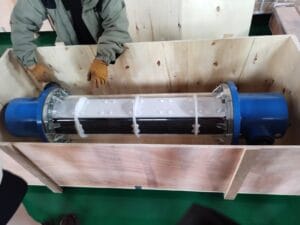

Aircraft and Aerospace Components: Titanium alloys are used in airframes, landing gear, and jet engines due to their high strength, lightweight, and resistance to extreme temperatures.

Armored Vehicles: Titanium is employed in the construction of armor plating for tanks and military vehicles, providing strong ballistic protection while reducing overall weight for enhanced mobility.

Naval Vessels: Titanium alloys are used in naval ship hulls, propeller shafts, and other critical components due to their resistance to corrosion from saltwater and harsh marine environments.

Missile and Rocket Systems: Titanium is integral in the production of missile and rocket casings, where strength and heat resistance are essential for performance under high-stress conditions.

Personal Protective Equipment (PPE): Titanium is used in lightweight body armor and helmets, offering enhanced protection without compromising mobility for soldiers.

Weapon Systems: Titanium alloys are used in advanced weaponry, such as gun barrels and missile launch systems, where durability, heat resistance, and lightweight properties are crucial.

In the military industry, the most commonly used grades of titanium are:

Grade 5 (Ti-6Al-4V): Known for its high strength, lightweight, and excellent corrosion resistance, Grade 5 is widely used in aerospace components, armor plating, and missile systems.

Grade 23 (Ti-6Al-4V ELI): A low-interstitial version of Grade 5, Grade 23 offers enhanced toughness and is used in critical applications like aircraft components and military medical implants.

Grade 9 (Ti-3Al-2.5V): This grade provides a balance of strength and formability, making it ideal for tubing in aircraft, military vehicles, and naval applications.

Grade 12: With added palladium for increased corrosion resistance, Grade 12 is used in naval vessels and components exposed to highly corrosive environments like saltwater.

Beta Titanium Alloys (e.g., Ti-10V-2Fe-3Al): These alloys offer high strength and fracture toughness, making them ideal for advanced military aircraft and missile systems.

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts