Titanium Products for 3D Printing

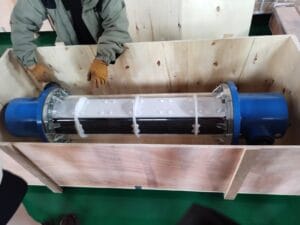

Our titanium products for 3D printing offer exceptional strength, lightweight properties, and high precision, making them ideal for creating complex, durable components. Perfect for industries like aerospace, medical, and automotive, titanium’s biocompatibility and corrosion resistance ensure superior performance in additive manufacturing applications.

Product Summary:

The advantages of titanium alloys in 3D printing include:

High Strength-to-Weight Ratio: Titanium alloys provide excellent strength while being lightweight, making them ideal for industries requiring high-performance components with reduced mass, such as aerospace and automotive.

Complex Geometries: Titanium alloys in 3D printing allow the production of intricate, customized designs that would be difficult or impossible to achieve through traditional manufacturing methods.

Biocompatibility: Titanium’s biocompatibility makes it perfect for medical applications, including implants and prosthetics, where precision and safety are critical.

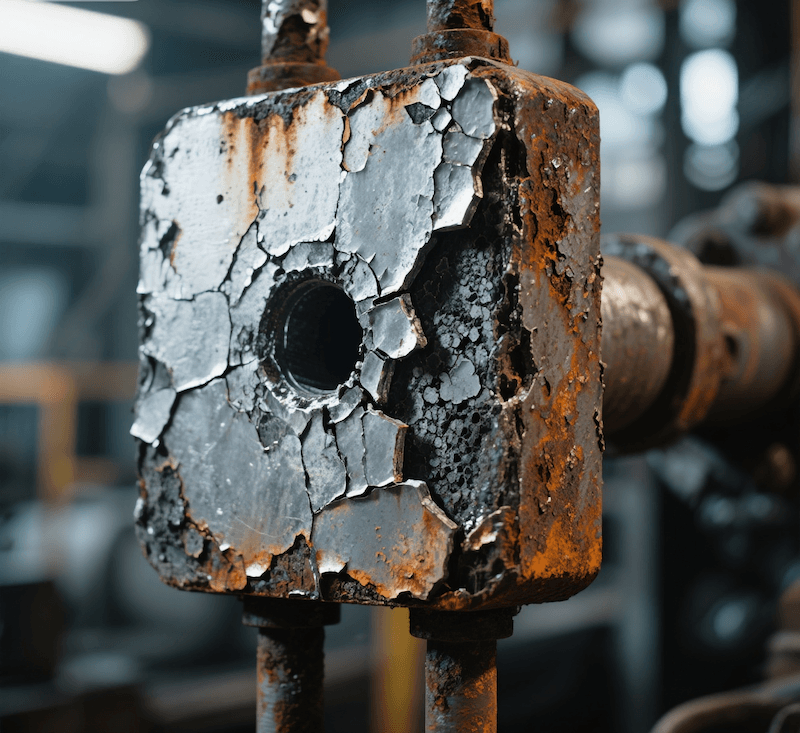

Corrosion Resistance: Titanium alloys resist corrosion from environmental factors and chemicals, ensuring long-lasting, durable parts for various industrial applications.

Reduced Material Waste: Additive manufacturing with titanium minimizes waste, as material is added layer by layer, making the process more sustainable and cost-effective.

Thermal Resistance: Titanium maintains its mechanical properties at high temperatures, making it suitable for components used in demanding environments, such as aerospace engines or industrial machinery.

3D printing titanium alloys are widely applied in various critical areas, including:

Aerospace Components: Used for lightweight yet strong parts like turbine blades, brackets, and engine components, where precision and high-performance materials are critical.

Medical Implants: Titanium’s biocompatibility and strength make it ideal for 3D printing custom implants, such as bone replacements, dental implants, and prosthetics tailored to individual patients.

Automotive Parts: Titanium alloys are used to create high-performance automotive components like exhaust systems, suspension parts, and engine components, reducing weight while maintaining strength.

Prosthetics and Orthotics: 3D-printed titanium allows for the customization of prosthetic limbs and orthopedic devices, providing a perfect fit and enhancing patient comfort and functionality.

Tooling and Manufacturing: Titanium alloys are used to 3D print specialized tools and molds that require strength, durability, and resistance to wear in industrial settings.

Energy and Power Generation: Titanium parts are used in the energy sector for components that must withstand high temperatures and corrosive environments, such as in gas turbines and power plants.

In 3D printing, the most commonly used grades of titanium are:

Grade 5 (Ti-6Al-4V): The most popular titanium alloy in 3D printing, Grade 5 offers a combination of high strength, lightweight properties, and excellent corrosion resistance, making it ideal for aerospace, medical, and automotive applications.

Grade 23 (Ti-6Al-4V ELI): An extra-low interstitial version of Grade 5, Grade 23 provides enhanced biocompatibility and toughness, making it the preferred choice for medical implants and devices.

Grade 2: Known for its excellent corrosion resistance and moderate strength, Grade 2 titanium is used in 3D printing for parts that require high corrosion resistance but do not need the high strength of alloys like Grade 5.

Grade 1: The softest and most ductile titanium grade, Grade 1 is used for applications that require excellent formability, corrosion resistance, and weldability, such as in chemical processing equipment and marine components.

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts