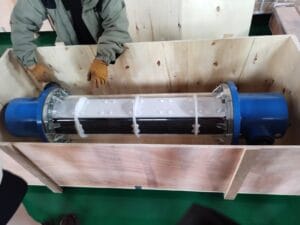

The advantages of titanium tubes include:

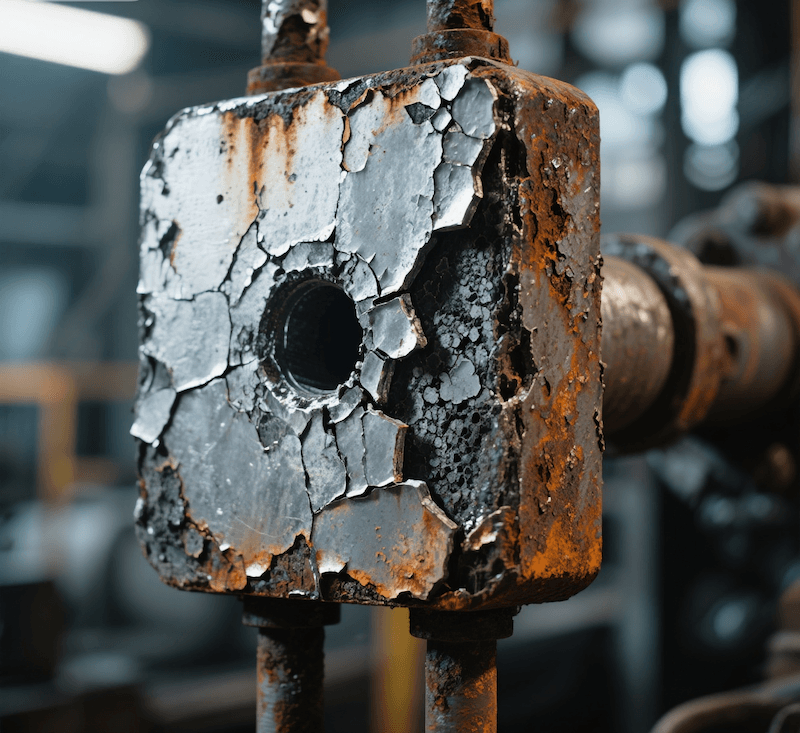

Corrosion Resistance: Titanium tubes offer exceptional resistance to corrosion from seawater, chemicals, and harsh environments, ensuring long-lasting performance.

High Strength-to-Weight Ratio: Titanium tubes provide excellent strength while being lightweight, making them ideal for applications where weight reduction is critical.

Durability: Titanium’s toughness and resistance to wear ensure that tubes maintain their integrity even under extreme conditions, reducing maintenance needs.

Heat Resistance: Titanium tubes retain their structural integrity at high temperatures, making them suitable for use in heat exchangers and other high-temperature applications.

Biocompatibility: In medical applications, titanium tubes are ideal for implants and surgical instruments due to their compatibility with the human body.

Versatility: Titanium tubes can be easily formed and adapted for a wide range of industries, including aerospace, marine, and industrial applications.