The advantages of titanium powder include:

High Strength-to-Weight Ratio: Titanium powder offers excellent strength while remaining lightweight, making it ideal for producing high-performance components.

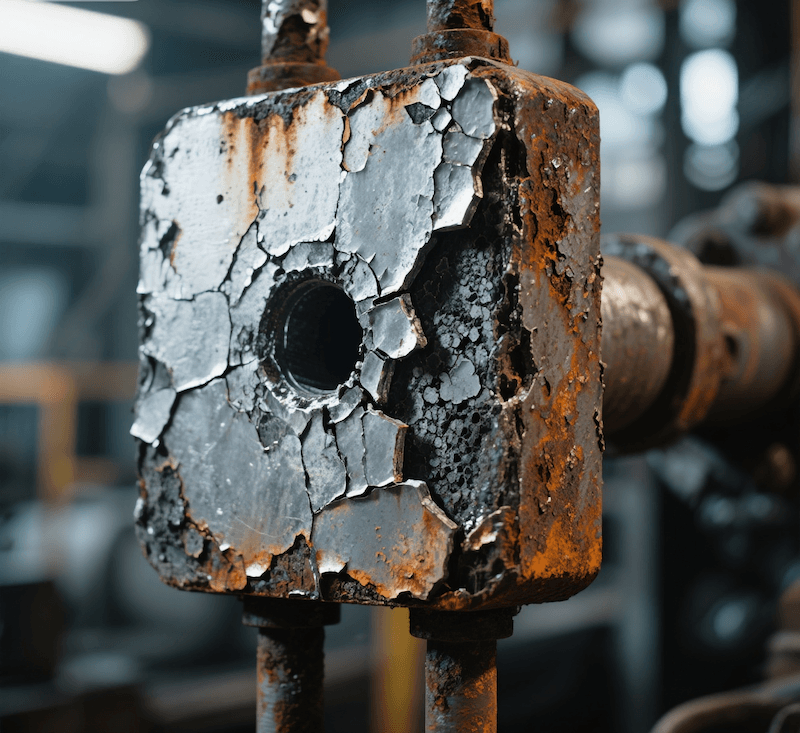

Corrosion Resistance: Titanium powder maintains titanium’s natural resistance to corrosion, making it suitable for harsh environments, including chemical and marine applications.

Versatility: Titanium powder is highly versatile and can be used in various manufacturing processes such as 3D printing, powder metallurgy, and thermal spraying.

Precision in Additive Manufacturing: In 3D printing, titanium powder allows for the production of complex, high-precision parts with superior mechanical properties.

Biocompatibility: Titanium powder is biocompatible, making it safe for medical applications such as implants and prosthetics.

Heat Resistance: Titanium powder can withstand high temperatures, making it suitable for components in aerospace and industrial applications that experience extreme heat.