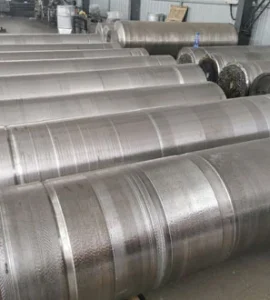

Titanium Ingot

Titanium ingots are high-purity, raw titanium blocks used as the primary material for manufacturing various titanium products. Known for their exceptional strength, corrosion resistance, and lightweight properties, titanium ingots are essential in industries such as aerospace, medical, automotive, and construction, where high-performance materials are required.

Product Summary:

The advantages of titanium ingots include:

High Purity: Titanium ingots offer excellent purity, ensuring superior material quality for advanced manufacturing processes in industries like aerospace and medical.

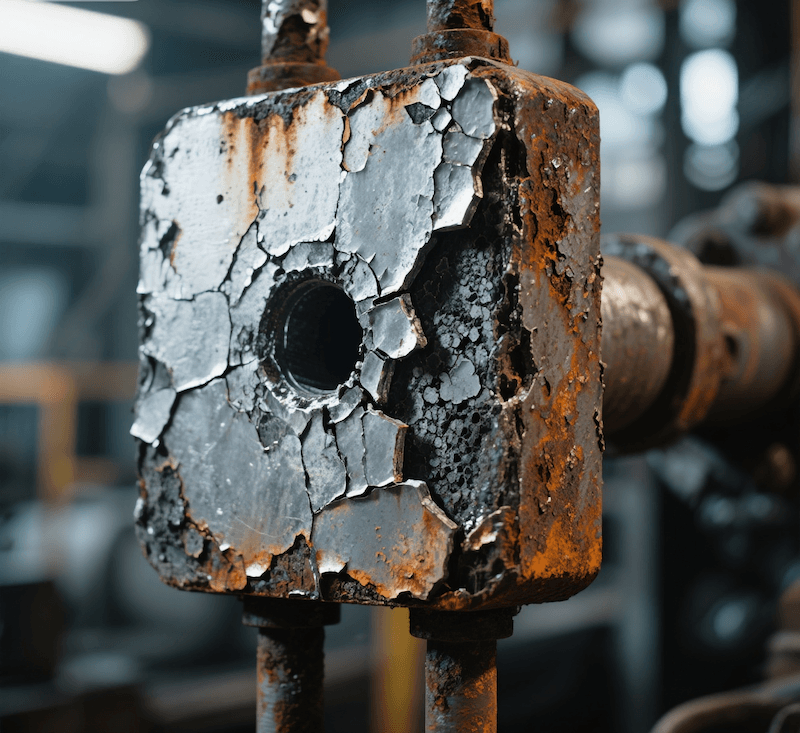

Strength and Durability: Titanium ingots provide high strength and durability, making them ideal for producing components that need to withstand extreme conditions.

Corrosion Resistance: Ingots maintain titanium’s natural resistance to corrosion, ensuring the longevity of the products manufactured from them, especially in harsh environments.

Lightweight: Despite their strength, titanium ingots are lightweight, which is beneficial for applications requiring high strength-to-weight ratios, such as in aerospace and automotive industries.

Versatility: Titanium ingots can be shaped, forged, or processed into various forms, making them suitable for a wide range of applications, from industrial parts to medical devices.

Biocompatibility: For medical and healthcare applications, titanium ingots are highly biocompatible, ensuring safety and integration with the human body in implants and prosthetics.

Titanium ingots are widely applied in various critical areas, including:

Aerospace: Used to manufacture aircraft components, engine parts, and structural elements due to their high strength, lightweight, and resistance to extreme temperatures.

Medical Devices: Titanium ingots are used to produce biocompatible implants, prosthetics, and surgical instruments, thanks to their excellent compatibility with the human body and corrosion resistance.

Automotive: In high-performance vehicles, titanium ingots are utilized to create lightweight, durable parts like engine components, exhaust systems, and suspension parts.

Marine Industry: Titanium ingots are applied in marine environments to produce corrosion-resistant components for ships, submarines, and offshore structures.

Construction: Used in architectural applications for producing strong, lightweight, and corrosion-resistant structural elements, roofing, and façades.

Energy Sector: Titanium ingots are used in the production of heat exchangers, power generation equipment, and components for oil and gas processing due to their durability in harsh environments.

The most commonly used grades of titanium ingots include:

Grade 1: This commercially pure titanium grade is known for its excellent corrosion resistance and formability, making it suitable for applications in the chemical and marine industries.

Grade 2: With a balance of strength, corrosion resistance, and weldability, Grade 2 titanium ingots are widely used in aerospace, medical, and industrial applications.

Grade 5 (Ti-6Al-4V): This alloy is the most commonly used titanium grade due to its high strength-to-weight ratio and excellent corrosion resistance, ideal for aerospace, medical implants, and automotive parts.

Grade 7: Enhanced with palladium, Grade 7 offers superior corrosion resistance, especially in highly corrosive environments, making it suitable for chemical processing and marine applications.

Grade 23 (Ti-6Al-4V ELI): Known for its extra-low interstitials, Grade 23 is used in medical implants and devices, offering high biocompatibility and toughness.

Gr1 Titanium Ingot 450mm Specification

| Product Name | Titanium ingot/Gr1 Titanium Ingot 450mm |

| Grade | GR1, GR2, GR5, GR5ELI, GR7, GR9, GR12, GR23, Ti-4Al-2V, Ti-4Al-1.5Mn. |

| Size | Diameter 200mm-600mm or as your request |

| Standard | GB/T-26060-2010, ASTM B977/B977M-19 |

| Brand Name | NONE/OEM |

| Application | chemical industry, Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability, High strength and light weight. |

| Technics | Vacuum Consumable Arc Furnace |

| Surface | Polished |

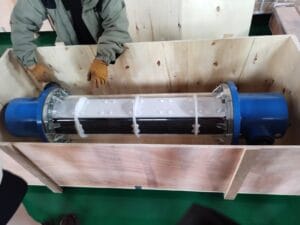

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2008; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts