Introduction

Titanium powder has become an essential material in modern manufacturing due to its versatility, high strength, and corrosion resistance. It plays a significant role in industries such as aerospace, medical, and additive manufacturing (3D printing). This article provides an overview of titanium powder, its key features, benefits, and the industries where it is making a significant impact.

What Is Titanium Powder?

Titanium powder consists of fine titanium particles produced through various methods, such as atomization, hydride-dehydride, or plasma rotating electrode process. These powders are used in manufacturing processes where the unique properties of titanium are required but in a more malleable form.

Titanium powder is primarily used in industries where high-performance materials are necessary, including aerospace and medical applications, as well as in advanced manufacturing techniques like 3D printing. It allows manufacturers to create complex parts with improved efficiency and precision, pushing the boundaries of what is possible in product design.

Key Features of Titanium Powder

1. High Strength and Lightweight

Titanium powder retains the high strength and lightweight properties of solid titanium, making it suitable for applications where reducing weight without sacrificing performance is crucial. This is particularly useful in industries like aerospace and automotive, where efficiency and weight reduction are key for improved performance.

2. Corrosion Resistance

Like solid titanium, titanium powder offers excellent corrosion resistance, even in harsh environments. This makes it suitable for manufacturing parts that are used in challenging conditions, such as marine and chemical processing applications, where resistance to rust and degradation is essential for maintaining component integrity.

3. Enhanced Fabrication Flexibility

Titanium powder provides enhanced fabrication flexibility, especially in additive manufacturing processes. It allows for the production of complex geometries that would be difficult or impossible to create using traditional manufacturing techniques. This flexibility opens new opportunities for engineers and designers to innovate without the limitations of conventional metalworking.

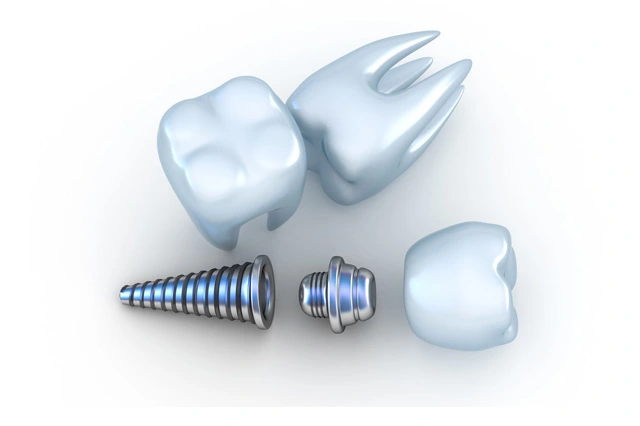

4. Biocompatibility

Titanium powder is biocompatible, making it an excellent choice for medical applications such as implants and prosthetics. It is non-toxic and does not react with bodily fluids, ensuring safety for long-term use in the human body. This property is crucial for ensuring that medical devices made from titanium powder can be safely implanted without causing adverse reactions.

Applications of Titanium Powder

1. Additive Manufacturing (3D Printing)

Titanium powder is widely used in additive manufacturing, particularly in the production of aerospace and medical components. Its ability to be sintered or melted layer by layer allows for the creation of intricate and lightweight parts that meet high performance standards. Additive manufacturing with titanium powder offers significant design freedom, enabling the production of custom parts with optimized performance characteristics.

2. Aerospace Industry

In the aerospace industry, titanium powder is used to manufacture lightweight and strong components, such as turbine blades and structural parts. The high strength and heat resistance of titanium make it ideal for critical aerospace applications, where performance, reliability, and efficiency are essential. Titanium powder’s use in 3D printing also allows for rapid prototyping and the production of parts with reduced material waste.

3. Medical Implants and Devices

Titanium powder is used in the production of medical implants and devices due to its biocompatibility and strength. It is utilized to create orthopedic implants, dental fixtures, and custom prosthetics that are tailored to the specific needs of patients. The ability to 3D print implants from titanium powder also ensures a precise fit, improving patient outcomes and reducing recovery times.

4. Chemical Processing

Titanium powder is also used in the chemical processing industry to create components that need to withstand corrosive environments. Heat exchangers, valves, and piping systems can be manufactured from titanium powder to ensure long-lasting durability. The corrosion-resistant nature of titanium makes it a valuable material for equipment that must operate in aggressive chemical environments.

5. Automotive and Motorsport

Titanium powder is used in the automotive industry for components that require a high strength-to-weight ratio, such as exhaust systems and engine parts. It is particularly popular in motorsport applications where reducing weight is essential for enhanced performance. The use of titanium powder allows manufacturers to create lightweight yet durable parts, contributing to improved vehicle dynamics and fuel efficiency.

Benefits of Using Titanium Powder

- Complex Part Production: Titanium powder allows manufacturers to create complex and intricate parts with ease, especially through additive manufacturing techniques. This capability is crucial for industries requiring high precision and design complexity.

- Reduced Material Waste: By using titanium powder in 3D printing, manufacturers can significantly reduce material waste, as the powder can be reused. This not only makes the process more cost-effective but also environmentally friendly by minimizing waste.

- High Performance: Titanium powder retains the desirable properties of solid titanium, including high strength, lightweight nature, and corrosion resistance, making it suitable for demanding applications. These properties are crucial for industries that require reliable, high-performance components.

Titanium Powder Grades and Their Uses

1. Commercially Pure (CP) Titanium Powder

Commercially pure titanium powder is used in applications that require excellent corrosion resistance and moderate strength. It is often used in medical implants and 3D printing of parts that need to be biocompatible, ensuring safety and longevity in medical applications.

2. Titanium Alloy Powder (Ti-6Al-4V)

Ti-6Al-4V is the most commonly used titanium alloy powder. It is known for its high strength, toughness, and corrosion resistance. This alloy is used in aerospace and automotive applications where high performance is essential. Its ability to withstand high stresses makes it ideal for critical components that must maintain integrity under demanding conditions.

Who Should Use Titanium Powder?

Titanium powder is ideal for industries that require strong, lightweight, and corrosion-resistant materials that can be fabricated into complex shapes. It is particularly valuable for manufacturers in aerospace, medical, chemical processing, and automotive sectors who need advanced materials for high-performance applications. The ability to create intricate components through additive manufacturing makes titanium powder an attractive option for those seeking innovation in design and manufacturing.

FAQ Section

- What Are the Main Benefits of Using Titanium Powder?

Titanium powder offers high strength, lightweight properties, corrosion resistance, and flexibility in manufacturing, making it ideal for high-performance applications. - Why Is Titanium Powder Used in 3D Printing?

Titanium powder allows for the production of complex, lightweight parts through additive manufacturing, improving efficiency and reducing material waste. - Is Titanium Powder Safe for Medical Use?

Yes, titanium powder is biocompatible, making it safe for use in medical implants and devices. - How Does Titanium Powder Benefit the Aerospace Industry?

Titanium powder is used to create lightweight and strong components for aircraft, helping improve fuel efficiency and performance. - What Are the Differences Between CP Titanium Powder and Titanium Alloy Powder?

CP titanium powder is commercially pure and offers excellent corrosion resistance, while titanium alloy powder (such as Ti-6Al-4V) has higher strength and toughness, suitable for more demanding applications. - Can Titanium Powder Be Used in Chemical Processing?

Yes, titanium powder is used to manufacture components that need to withstand corrosive substances in the chemical processing industry. - What Applications Benefit Most from Titanium Alloy Powder?

Titanium alloy powder is often used in aerospace and automotive applications due to its high strength and performance characteristics. - Is Titanium Powder Used in Automotive Manufacturing?

Yes, titanium powder is used to create lightweight and high-strength components for automotive and motorsport applications, such as exhaust systems and engine parts. - How Does Titanium Powder Reduce Material Waste?

In additive manufacturing, titanium powder can be reused, significantly reducing material waste compared to traditional machining processes. - Can Titanium Powder Be Used for Marine Applications?

Yes, titanium powder can be used to manufacture components that need to withstand saltwater corrosion, making it suitable for marine environments. - Why Is Titanium Powder Preferred for Medical Implants?

Titanium’s biocompatibility and strength make it a preferred material for medical implants and devices, ensuring safety and longevity. - What Is the Most Common Titanium Alloy Powder Used?

The most common titanium alloy powder is Ti-6Al-4V, known for its high strength, toughness, and versatility in demanding applications. - How Does Titanium Powder Compare to Solid Titanium?

Titanium powder retains the properties of solid titanium but offers greater flexibility in fabrication, making it ideal for creating complex geometries. - Can Titanium Powder Be Used in Heat Exchangers?

Yes, titanium powder is used to create components for heat exchangers due to its excellent thermal conductivity and corrosion resistance. - What Industries Benefit Most from Titanium Powder?

Industries such as aerospace, medical, chemical processing, automotive, and marine benefit greatly from the unique properties of titanium powder.

Conclusion

Titanium powder is revolutionizing modern manufacturing with its versatility, strength, and corrosion resistance. Its use in industries like aerospace, medical, and additive manufacturing highlights its importance in creating complex, high-performance parts with reduced material waste. Choosing titanium powder ensures reliability, efficiency, and advanced performance in demanding applications.