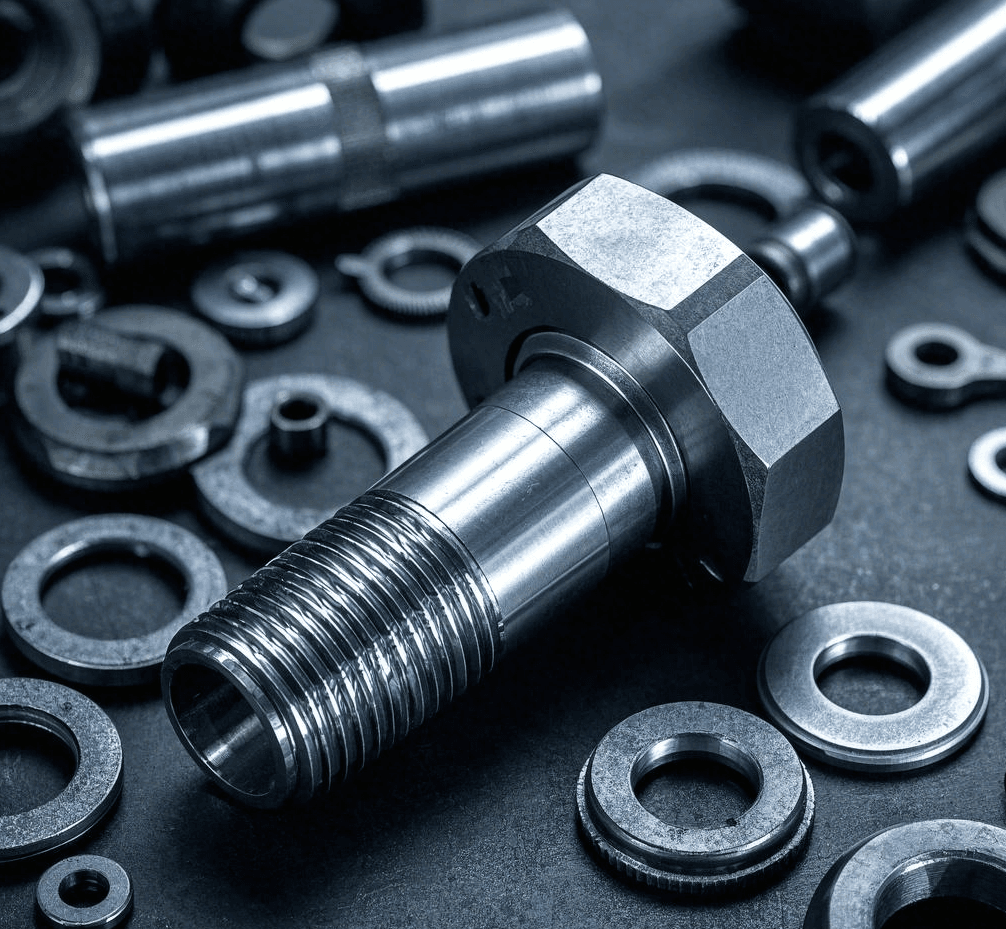

Introduction: The Importance of Durability in Fasteners

Durability is a key factor when selecting fasteners for demanding applications, as their performance affects the longevity and safety of structures and equipment. Titanium and steel are two widely used materials, each with its strengths. But how does titanium compare to steel in terms of durability?

Titanium fasteners are as durable as steel fasteners and often outperform them in specific applications, thanks to their corrosion resistance, fatigue strength, and long-term stability.

Let’s explore the key factors that contribute to the durability of titanium and steel fasteners and why titanium often proves to be the better choice.

How Does Corrosion Resistance Impact Durability?

Corrosion is a major threat to the durability of fasteners, especially in environments exposed to moisture, chemicals, or saltwater. Titanium fasteners resist corrosion exceptionally well due to their natural oxide layer, which protects against rust and chemical degradation.

In my experience:

• Titanium: Maintains structural integrity over time in corrosive environments such as marine or chemical processing.

• Steel: Even stainless steel can corrode over time in extreme conditions, requiring additional coatings or treatments.

This superior corrosion resistance makes titanium fasteners more durable in harsh environments, reducing the risk of failure and the need for replacements.

How Does Fatigue Resistance Contribute to Long-Term Durability?

Fatigue resistance refers to a material’s ability to withstand repeated cycles of stress without cracking or failing. Titanium fasteners excel in this area, making them highly durable under dynamic and high-stress conditions.

Applications I’ve observed include:

• Aerospace: Titanium fasteners endure the repeated stress of takeoffs, landings, and in-flight vibrations.

• Automotive: Engine components with titanium fasteners resist wear from continuous mechanical stress and thermal cycling.

Steel fasteners can also offer good fatigue resistance but are more prone to wear and deformation in cyclic loading compared to titanium.

How Does Wear Resistance Affect Durability?

Durability is often influenced by how well fasteners resist surface wear and abrasion over time. Titanium’s surface hardness and natural toughness make it resistant to wear in many applications.

From my perspective:

• Titanium: Resists deformation and retains its shape in environments with high friction or contact stress, such as industrial machinery.

• Steel: Certain hardened steel grades are more wear-resistant than titanium, but they are also more susceptible to corrosion, which can compromise durability.

This wear resistance, combined with corrosion protection, allows titanium fasteners to outlast steel in most applications.

How Does Performance in High Temperatures Influence Durability?

Durability in high-temperature environments is another area where titanium fasteners often surpass steel. Titanium maintains its strength and mechanical properties at elevated temperatures, making it more stable over time.

Key examples:

• Titanium: Performs well in turbine engines, exhaust systems, and other heat-intensive applications.

• Steel: May lose strength or deform under prolonged high-temperature exposure unless specially alloyed.

For me, this thermal stability makes titanium fasteners ideal for applications requiring durability in extreme heat.

How Do Long-Term Maintenance Needs Compare?

The need for frequent maintenance or replacement affects the long-term durability of fasteners. Titanium fasteners require minimal upkeep due to their corrosion resistance and wear resistance.

In contrast:

• Titanium: Retains performance with little to no maintenance, reducing long-term costs.

• Steel: May require protective coatings or regular inspections in corrosive environments to maintain durability.

This low-maintenance advantage makes titanium a durable and cost-effective solution for critical applications.

Are There Situations Where Steel Is More Durable?

While titanium excels in many areas, steel fasteners can offer superior durability in specific cases, particularly when absolute strength or cost-effectiveness is a priority.

Examples include:

• Ultra-High Loads: Hardened steel fasteners are better suited for applications requiring extremely high tensile strength.

• Cost-Sensitive Applications: Steel fasteners are more affordable and practical for less demanding environments.

However, the higher weight and susceptibility to corrosion of steel often offset these advantages in long-term durability.

Claim: Why Titanium Fasteners Match or Surpass Steel in Durability

Titanium fasteners are as durable as steel fasteners and often outperform them in applications where corrosion resistance, fatigue strength, and long-term stability are critical. Their ability to withstand harsh environments with minimal maintenance ensures consistent performance and extended service life.

Conclusion: Titanium’s Durability Advantage

Titanium fasteners offer unmatched durability in challenging conditions, making them a superior choice for industries like aerospace, marine, and automotive. While steel remains an excellent material for certain applications, titanium’s combination of corrosion resistance, fatigue strength, and thermal stability ensures it remains a leading choice for long-term reliability.

Titanium fasteners represent the pinnacle of durability in engineering materials. Their ability to thrive in demanding environments makes them an investment in safety, efficiency, and longevity.