Introduction

Triply circle material has become a preferred choice in the manufacturing industry due to its unique three-layer construction, offering several key advantages. This material enhances durability, ensures even heat distribution, and provides versatile applications, making it ideal for high-quality cookware and other industrial uses. This article explores the advantages and practical applications of triply circles for manufacturers and factories, highlighting their value in production processes.

What Is Triply Circle?

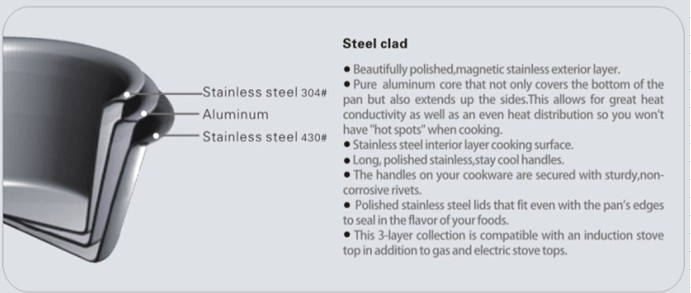

Triply circle is a specialized material that consists of three bonded layers, each with its distinct role and properties:

Stainless Steel (Outer Layer)

- The outer layer of triply circle is composed of high-quality stainless steel, which provides exceptional durability, corrosion resistance, and structural strength. This layer ensures that the cookware or component remains robust and can withstand heavy use without degrading. Additionally, the stainless steel exterior makes triply circle compatible with all types of stovetops, including induction, gas, electric, and ceramic, adding versatility to its applications.

Aluminum (Core Layer)

- The middle layer of triply circle is made of aluminum, which serves as the core material. Aluminum is well-known for its excellent thermal conductivity, allowing for rapid and even heat distribution across the entire cooking or heating surface. This core ensures that heat spreads uniformly, eliminating the risk of hot spots that can lead to uneven cooking or heating. The aluminum core also contributes to the overall energy efficiency of the cookware, making it quicker to reach the desired temperature and maintain it consistently.

Stainless Steel (Inner Layer)

- The inner layer, which comes into direct contact with food, is also made of stainless steel. This layer provides a safe, non-reactive cooking surface that won’t alter the taste, quality, or color of the food being prepared. Stainless steel is resistant to staining, pitting, and corrosion, making it ideal for both acidic and alkaline ingredients. The non-reactive nature of stainless steel ensures that no unwanted chemicals or flavors are transferred to the food, providing a healthier cooking experience.

Key Features of Triply Circle

- Heat Compatibility: The stainless steel outer layer makes triply circle adaptable to all types of heat sources, including induction. This is particularly valuable for manufacturers looking to create versatile cookware that can be used on various stovetop types without compatibility issues.

- Non-Reactive Surface: The stainless steel inner layer ensures that the material is non-reactive, making it safe for use with all types of ingredients, from acidic tomatoes to alkaline baking soda.

- Efficient Heat Conduction: The aluminum core ensures efficient and even heat distribution, reducing cooking times and enhancing energy efficiency, which is beneficial for both manufacturers and end-users.

Why Is Each Layer Important?

- Stainless Steel Outer Layer: Provides corrosion resistance, structural integrity, and compatibility with all heat sources, including induction.

- Aluminum Core: Delivers rapid and even heat conduction, ensuring consistent cooking results without hotspots.

- Stainless Steel Inner Layer: Offers a non-reactive, safe cooking surface that maintains the quality and flavor of the food.

Key Advantages of Triply Circle for Manufacturers

1. Enhanced Durability

Triply circle features two layers of stainless steel, offering excellent resistance to warping, corrosion, and scratches. This durability is crucial for products that endure heavy use, such as cookware. For manufacturers, this means reduced returns, fewer customer complaints, and a better reputation for delivering long-lasting, high-quality products.

2. Superior Heat Distribution

The aluminum core within the triply circle is a highly effective heat conductor, ensuring even heat distribution throughout the entire surface. Cookware made from triply circle heats up quickly and maintains a consistent temperature, significantly improving the cooking experience for the end-user. Manufacturers benefit from being able to produce products that offer reliable and efficient performance.

3. Versatility in Production

Triply circle is an adaptable material that can be used to manufacture a wide range of products, such as non-stick cookware, bakeware, and industrial components. The stainless steel layers make it compatible with all stovetop types, including induction, while the non-reactive cooking surface ensures safety for various cooking methods. This versatility allows manufacturers to diversify their product offerings and cater to different market demands.

4. Cost-Effective Production

Though initially more expensive than single-layer materials, triply circle proves to be cost-effective in the long term. The extended lifespan and reduced risk of material defects lead to fewer replacements, greater customer satisfaction, and ultimately, lower production costs for manufacturers. The improved durability of triply circle also translates into fewer quality control issues during production.

5. Improved Quality Control

Triply circle ensures consistent quality in manufacturing. The even heat distribution provided by the aluminum core helps maintain product consistency, while the stainless steel layers add structural robustness. This consistency allows manufacturers to maintain high-quality control standards, resulting in reliable and well-performing products that meet or exceed customer expectations.

Applications of Triply Circle in Manufacturing

1. Cookware Production

- Application Environment: Triply circle is extensively used in the production of high-quality cookware, including frying pans, saucepans, and stockpots. These products are used in both household and professional kitchens, where durability and performance are crucial.

- Key Characteristics: The even heat distribution offered by the aluminum core ensures consistent cooking results, while the stainless steel inner layer preserves the flavor and quality of food. Cookware made from triply circle is preferred for its resistance to wear and ability to withstand rigorous use.

2. Bakeware Manufacturing

- Application Environment: Triply circle is also used in the production of bakeware such as baking trays, cake pans, and muffin molds. These products are utilized by professional bakers and home users alike, who need reliable bakeware for consistent baking results.

- Key Characteristics: The aluminum core ensures even heat distribution, which is critical for preventing uneven baking and undercooked or overcooked spots. Additionally, the stainless steel layers provide resistance to corrosion and ease of maintenance, making triply circle bakeware durable and easy to clean.

3. Industrial Applications

- Application Environment: Triply circle is used in various industrial environments that require materials with excellent thermal performance and durability, such as heat exchangers and industrial processing equipment.

- Key Characteristics: The aluminum core allows for rapid and efficient heat transfer, which is essential in industrial processes that demand consistent thermal management. The stainless steel layers add the necessary strength and corrosion resistance, making triply circle a suitable material for challenging industrial conditions.

4. Non-Stick Cookware Production

- Application Environment: Triply circle is often used as the base material for non-stick cookware, which is widely used in both residential and commercial kitchens.

- Key Characteristics: The aluminum core’s even heating capabilities enhance the performance of non-stick coatings, ensuring food is cooked evenly and released easily from the surface. This application is particularly popular among health-conscious consumers who prefer low-fat cooking, as the non-stick surface allows for minimal use of oil or butter. The combination of durability, even heat distribution, and non-stick convenience makes triply circle an excellent choice for producing high-performance non-stick cookware.

FAQs Section

- What Are the Main Advantages of Triply Circle for Manufacturers?

Triply circle offers enhanced durability, superior heat distribution, versatility in production, cost-effectiveness, and improved quality control for manufacturers. - How Does Triply Circle Improve Cookware Quality?

The aluminum core ensures even heat distribution, while the stainless steel layers provide durability, resulting in cookware that performs consistently and lasts longer. - Is Triply Circle Cost-Effective for Manufacturers?

Yes, despite higher initial costs, triply circle is cost-effective due to its long lifespan, reduced material defects, and fewer replacements needed. - What Types of Products Can Be Made from Triply Circle?

Triply circle is used to manufacture cookware, bakeware, non-stick cookware, and industrial components requiring excellent heat conductivity and durability. - Why Is Triply Circle Popular for Non-Stick Cookware?

The even heating provided by the aluminum core enhances the performance of non-stick coatings, improving cooking results and making cleanup easier. - Can Triply Circle Be Used for Industrial Applications?

Yes, triply circle can be used for industrial applications where heat conductivity and durability are critical, such as components for heat exchangers. - How Does Triply Circle Benefit Factories in Quality Control?

Triply circle ensures consistent product performance due to even heat distribution and robustness, helping factories maintain high quality control standards. - Is Triply Circle Suitable for Induction Cooktops?

Yes, the stainless steel outer layer of triply circle makes it compatible with induction cooktops, making it versatile for various cooking appliances. - What Makes Triply Circle a Durable Material for Manufacturing?

The stainless steel layers provide resistance to warping, corrosion, and scratches, making triply circle a highly durable option for manufacturing. - Why Should Manufacturers Consider Using Triply Circle?

Manufacturers should consider triply circle for its superior performance, durability, versatility, and the ability to produce high-quality, reliable products that meet customer demands.

Conclusion

Triply circle offers numerous advantages for manufacturers and factories, including enhanced durability, superior heat distribution, and versatility in product applications. Its unique construction makes it ideal for producing high-quality cookware, bakeware, and industrial