Custom Titanium Medical Forgings for Orthopedic Applications

we specialize in manufacturing custom titanium medical forgings for use in orthopedic implants, spinal devices, trauma systems, and surgical tools. With over a decade of forging experience and strict compliance to international medical standards, our forged blanks are trusted by implant OEMs and machining companies worldwide.

Your Trusted Supplier of Titanium Medical Forgings

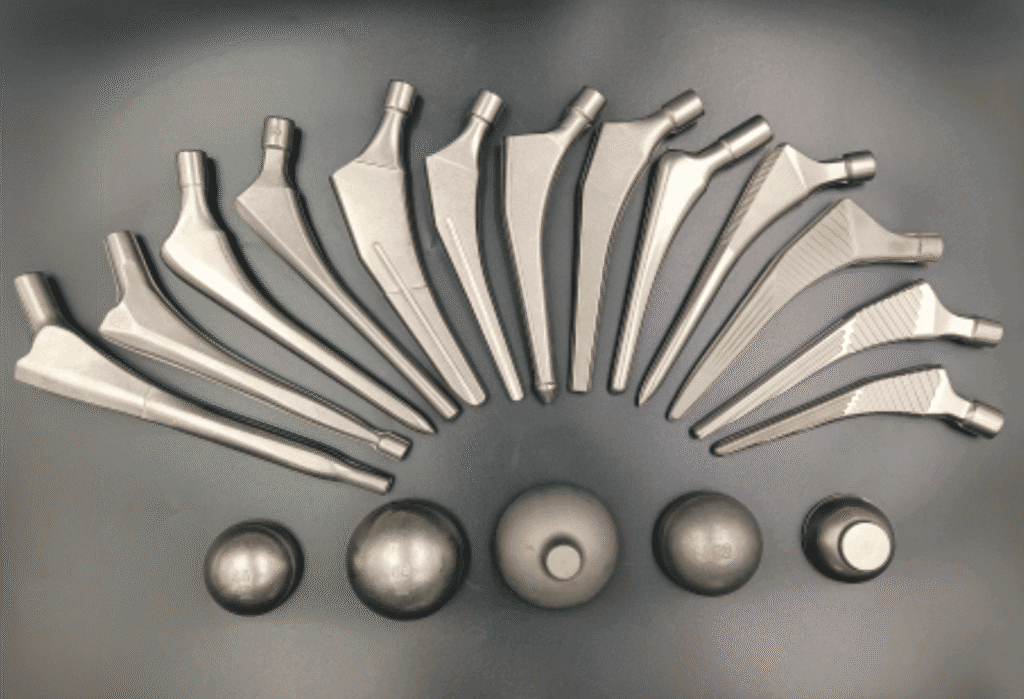

Titanium Hip Stem Forging

Designed for load-bearing stability and biocompatibility, our forged hip stems provide the ideal foundation for total hip replacement systems. Available in multiple angles and geometries, ready for CNC machining.

Titanium Knee Implant Forging

This precision-forged knee joint blank is optimized for anatomical shape and structural integrity. Ideal for high-wear areas requiring durability, corrosion resistance, and smooth articulation.

Titanium Trauma Plate Forging

Lightweight yet strong, our trauma plate forgings are tailored for fracture repair applications. They support easy contouring and meet stringent requirements for fatigue strength and clean machining.

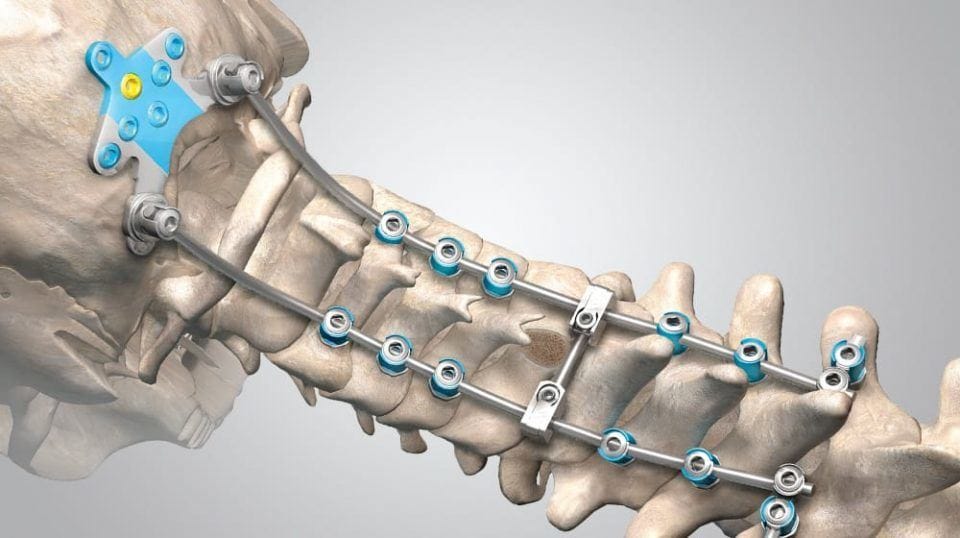

Titanium Spinal Implant Forging

Used in spinal fixation systems, these forgings ensure precise fit, exceptional strength-to-weight ratio, and long-term stability within the vertebral column. Fully customizable to your fixation design.

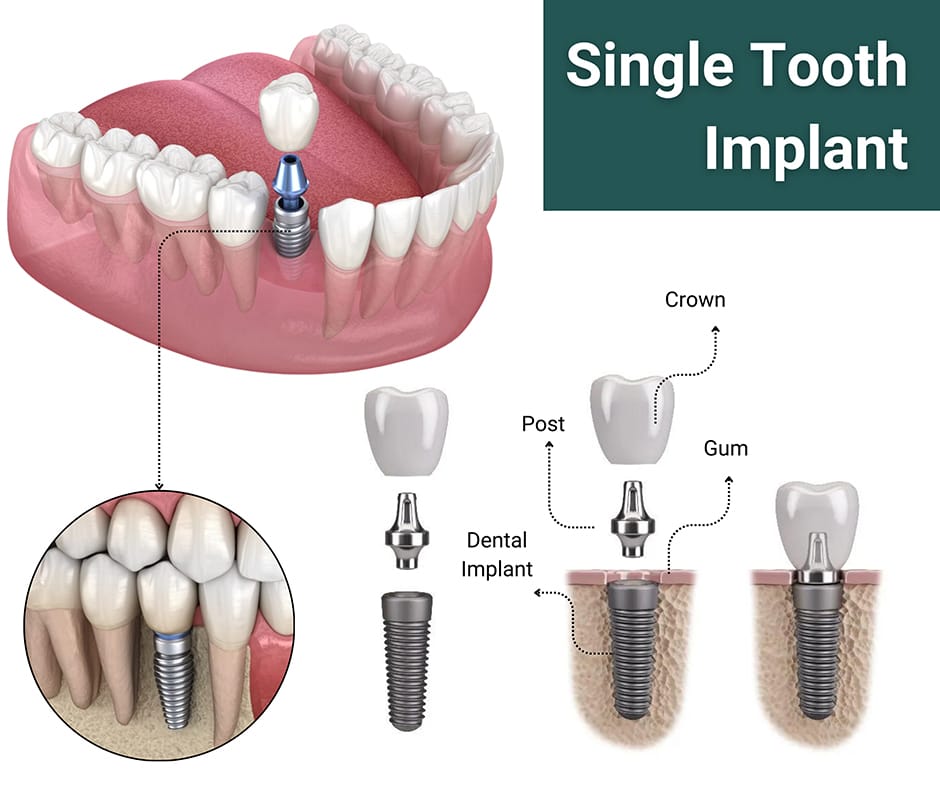

Titanium Dental Implant Forging

Forged from Grade 23 titanium for excellent purity and tissue compatibility, these blanks are ideal for dental implant posts and abutments. Excellent machinability and corrosion resistance.

Surgical Instrument Titanium Forging

Engineered for surgical-grade precision, these titanium blanks are corrosion-resistant, lightweight, and ideal for instruments such as bone chisels, retractors, and orthopedic forceps.

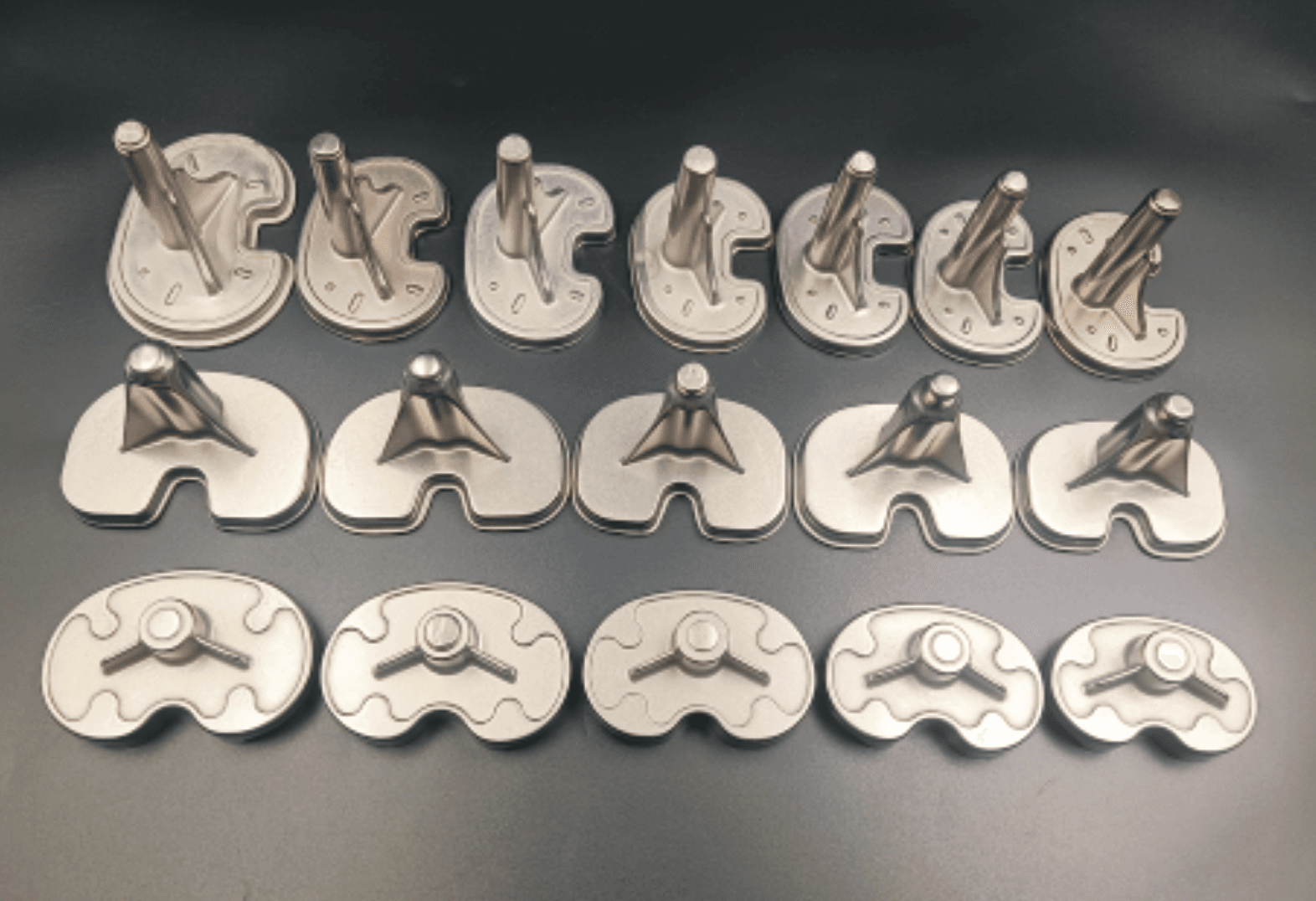

Orthopedic Titanium Forging Set

A comprehensive range of forging blanks for orthopedic OEMs—covering hips, knees, spine, trauma, and dental applications. All produced under strict quality systems and export-ready.

Custom Titanium Medical Forging

From prototypes to batch production, we offer fully customized forging services based on your drawings and requirements. Start from a certified blank, finish with a world-class implant.

Tailor-Made Titanium Medical Forgings for Your Implant Projects

We forge blanks for hip stems, knee joints, trauma plates, spinal devices, and dental implants, all shaped to suit your machining process and implant specifications.

• Application-Specific Configurations

Whether for load-bearing orthopedic implants, spine fixation systems, or dental components, we ensure each forging meets the mechanical and regulatory requirements for safe and long-term implantation.

• Controlled Mechanical Properties

Tensile strength, fatigue resistance, and grain flow can be controlled through forging and heat treatment to match your desired implant performance and safety standards.

• Certified Medical Titanium Grades

Choose from Ti-6Al-4V (Grade 5) or Ti-6Al-4V ELI (Grade 23)—both offering excellent biocompatibility, corrosion resistance, and processability for surgical and implant applications.

At Xunyang, we don’t just supply forgings—we collaborate to develop implant-grade titanium solutions that meet global standards and deliver lasting value. Contact us today to explore custom options that advance your medical product performance.

Streamline Your Custom Titanium Medical Forgings Order with Xunyang Titanium

01.

1. Understand Your Implant Requirements

We begin by reviewing your technical needs—implant type, anatomical location, loading conditions, biocompatibility needs, and mechanical performance targets.

02.

2. Define the Application

Let us know your specific use case—hip replacement, knee joint, spinal fixation, trauma repair, or dental implant—so we can recommend the most suitable forging design and material grade.

03.

3. Select the Material and Processing

Choose the titanium grade best suited for your device—Ti-6Al-4V (Grade 5) for general strength, or Ti-6Al-4V ELI (Grade 23) for high-purity, implant-grade performance. We’ll adjust the grain structure and forging pressure accordingly.

04.

4. Submit Your Design or Specification

Share your drawings, dimensions, tolerances, or special machining needs. We’ll deliver a tailored forging solution that aligns with your product design and regulatory standards.

Why Choose Xunyang Titanium for Titanium Medical Forgings?

Flexible Order Quantities

From single test samples to full-scale production runs, we support low- and high-volume orders to match your development and manufacturing schedules.

Experienced Forging Engineers

Our team has over 10 years of experience in medical-grade titanium forging, serving orthopedic, dental, and surgical device manufacturers worldwide.

Competitive Pricing

We offer cost-effective forging solutions without compromising material integrity or implant safety—helping you maintain both competitiveness and compliance.

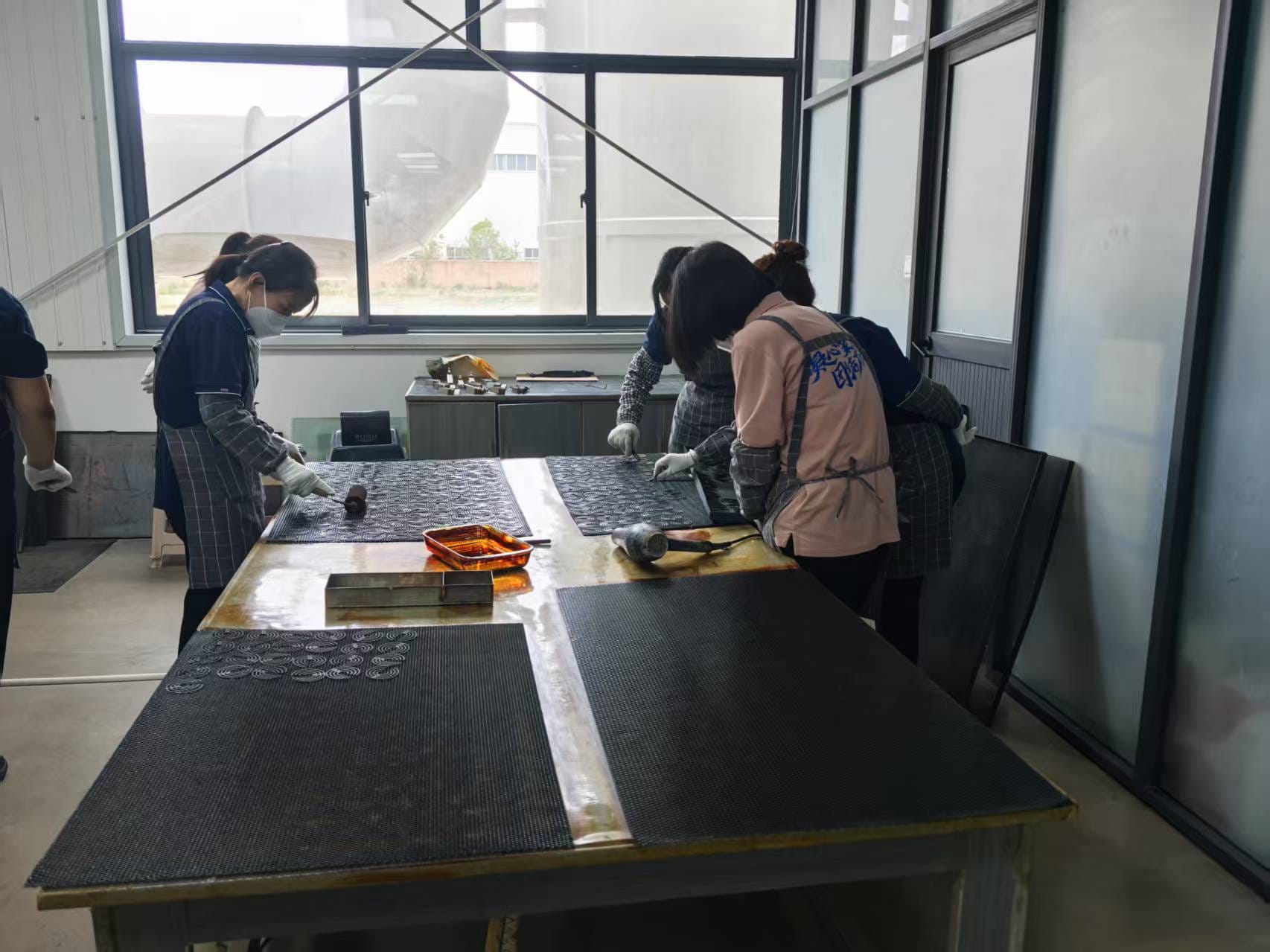

In-House Process Control

Every step—from tooling design to forging, heat treatment, and quality inspection—is completed in-house, ensuring consistency and accountability.

Reliable Lead Times

Our optimized workflow and stable production capacity enable fast, on-time deliveries, even for complex custom orders.

Certified Medical Quality

We adhere to ISO 13485 and ASTM F136/F67 standards, ensuring every forging meets the mechanical and biocompatibility requirements of modern medical implants.

Your Complete Guide to Sourcing Titanium Medical Forgings

This guide showcases the versatility and clinical reliability of precision-forged titanium components across medical sectors, from joint replacement systems to minimally invasive surgical tools. Whether you’re sourcing for custom prototypes or large-scale production, this resource will help you select the right titanium forging solution—engineered for precision, regulatory compliance, and patient-centered performance.

Table of Contents

Chapter 1 — What Are Titanium Medical Forgings?

Commonly used in orthopedic implants (hip stems, knee joints), spinal fixation systems, trauma plates, and dental implants, titanium medical forgings serve as foundational components for devices that must perform reliably under physiological loads and in biological environments.

Chapter 2 — Advantages of Titanium Medical Forgings

⸻• Implant-Grade Strength and Reliability

Forging aligns the grain structure of titanium, significantly improving fatigue resistance, tensile strength, and dimensional stability—critical for load-bearing implants such as hip stems and spinal rods.

⸻• Excellent Biocompatibility

Medical-grade titanium alloys like Ti-6Al-4V ELI (Grade 23) exhibit exceptional compatibility with human tissues, reducing the risk of inflammation, allergic reaction, or implant rejection.

⸻• Lightweight for Patient Comfort

Titanium offers high strength-to-weight ratio, making it lighter than stainless steel while maintaining durability—important for both patient mobility and surgical handling.

Forging enables close control over geometry and tolerances, ideal for anatomically shaped components like femoral stems, trauma plates, and dental implant blanks.

⸻• Reduced Material Waste and Better Machinability

Compared to CNC machining from bar stock, near-net shape forgings minimize material waste and lower downstream processing costs.

Thanks to these benefits, titanium medical forgings are widely used in orthopedic, dental, and surgical implant manufacturing, offering a durable, biocompatible, and cost-efficient solution that meets the rigorous demands of modern healthcare systems.

Chapter 3 – Tailor-Made Titanium Medical Forgings for Your Needs

Experience precision forging and application-specific performance, designed to meet the complex requirements of modern medical technology.

Our forgings can be produced in a wide variety of sizes and contours to meet implant system requirements, from large orthopedic constructs to compact dental components. Whether your need is for high-load bearing structures or precision surgical tool blanks, we deliver engineered components that combine compatibility, strength, and safety.

Available Forging Types Include:

• Hip Stem Forgings: Optimized for mechanical strength and anatomical fit.

• Knee Joint Blanks: Designed for articulating surfaces and modular systems.

• Spinal Fixation Parts: Compact and load-stable for vertebral integration.

• Bone Plates & Screws: Thin, strong, and contour-friendly for trauma repair.

• Dental Implant Blanks: High purity and corrosion resistance for oral integration.

• Surgical Tool Forgings: Lightweight and anti-corrosive for repeated sterilization.

Each forging is carefully crafted from Ti-6Al-4V or Ti-6Al-4V ELI (Grade 5 / 23) to match the structural and biological requirements of your device.

From orthopedic implants to minimally invasive tool systems, Xunyang’s custom titanium forgings help ensure long-term implant success, processing efficiency, and regulatory compliance.

Choose Xunyang Titanium for forgings that are not only precisely made—but purpose-built for life-saving performance.

Chapter 4 — Applications of Titanium Medical Forgings

Used in total hip and knee replacements, forged titanium components provide the load-bearing capacity and fatigue resistance required for long-term implantation in weight-bearing joints.

Recommended Spec:

• Forging Type: Hip stem, femoral knee component

• Material: Ti-6Al-4V ELI (Grade 23)

• Surface: Shot-blasted or semi-machined

Tips: Ensure anatomical curvature and dimensional accuracy for implant stability and surgical compatibility.

Spinal rods, cages, and pedicle screw bases are forged from titanium for lightweight support and excellent mechanical reliability within the vertebral column.

Recommended Spec:

• Forging Type: Rod, spacer, connector

• Material: Ti-6Al-4V or customized titanium alloy

• Finish: Machined or rough-forged for secondary processing

Tips: Confirm tight tolerances and fatigue resistance. Use CNC-ready blanks to reduce machining time.

Bone plates and fixation screws require slim-profile but strong materials. Titanium forgings offer contourability and high tensile properties for fracture stabilization.

Recommended Spec:

• Forging Type: Flat bar, low-profile plate

• Material: Grade 23 titanium

• Surface: As-forged or polished

Tips: Consider bending radius and pre-hole location for ease of surgical application and optimal bone alignment.

Dental posts and abutments use small-dimension forged blanks to ensure precision, purity, and corrosion resistance in oral environments.

Recommended Spec:

• Forging Type: Rod or bar for turning

• Material: CP Titanium (Grade 4) or Grade 23

• Surface: Turned or polished

Tips: Ensure low impurity levels and consistent grain size. Use ELI grade for enhanced biocompatibility.

Titanium is ideal for producing lightweight, reusable surgical tools such as forceps, scissors, and bone chisels—especially in minimally invasive procedures.

Recommended Spec:

• Forging Type: Strip, block, or preform

• Material: Ti-6Al-4V or CP Titanium

• Surface: Raw forged or CNC-ready

Tips: Select grades with optimal hardness and edge retention. Ensure excellent corrosion resistance to withstand sterilization cycles.

R&D teams require small-batch, precision-forged blanks for developing new implant systems and tools. Titanium’s versatility makes it ideal for pilot-scale innovation.

Recommended Spec:

• Forging Type: Small bar, plate, or sample blank

• Material: Ti-6Al-4V ELI or custom alloys

• Surface: Machined or raw

Tips: Support low-MOQ prototyping, and request traceable mill certificates and heat batch control for testing validation.

Chapter 5 – Best Practices for Handling and Using Titanium Medical Forgings

Follow these best practices to maximize the reliability and safety of your medical forging applications.

⸻• Avoid Surface Contamination

Handle forgings with clean gloves. Avoid contact with oil, dust, or foreign metals, as these may interfere with subsequent machining or sterilization.

⸻• Prevent Mechanical Damage

Do not drop or strike titanium blanks. Even small dents or scratches may compromise structural integrity or result in localized stress concentrations.

⸻• Use Biocompatible Coolants and Fluids

During machining, use only approved coolants that do not contain chlorine or sulfur compounds, which may cause corrosion or residue buildup.

Avoid excessive heat buildup which can alter grain structure or introduce internal stress. Use sharp tools and proper speeds/feeds to maintain dimensional precision.

⸻• Maintain Batch Traceability

Keep forging batches separated and clearly labeled. Maintain traceability records for material certificates, heat treatment logs, and dimensional inspections.

⸻• Store in a Clean, Dry Environment

Store titanium forgings in a controlled environment free of moisture, dust, and acidic vapors. Avoid direct floor contact—use clean trays or racks.

⸻• Schedule Regular Quality Inspections

Before further processing or dispatch, inspect forgings for surface defects, warping, or tolerance deviations. Use CMM or visual magnification tools when applicable.

At Xunyang Titanium, we prioritize product safety and compliance from forging to final use. All our medical-grade titanium forgings are produced under strict ISO 13485 and ASTM F136 standards, with traceable quality documentation provided upon delivery.

Chapter 6 – Technical Specifications of Titanium Medical Forgings

Each forging undergoes closed-die hot forging, followed by controlled heat treatment to achieve stable microstructure and dimensional integrity. We strictly follow international standards including ASTM F136, ASTM F67, and ISO 13485 throughout production.

• Tensile strength reaches 860–950 MPa, depending on material grade and heat treatment.

• Yield strength is maintained above 795 MPa, supporting high-load applications such as hip stems and spinal rods.

• Elongation at break is 10% or greater, offering reliable ductility for complex surgical contouring.

• Hardness typically ranges between HRC 30–36, balancing machinability and wear resistance.

• Grain size is refined to ASTM 5 or finer to meet implant-grade consistency and fatigue reliability.

All forgings are available in as-forged, semi-machined, or shot-blasted finish based on customer requirements. Surface condition is optimized for secondary machining, coating, or sterilization processes.

Our products are compatible with CNC, EDM, and drilling operations, and are widely used as preforms for hip replacements, knee components, trauma plates, dental implants, and spinal fixation devices.

Whether you’re producing small-scale prototypes or high-volume implant components, Xunyang’s titanium medical forgings deliver the precision, purity, and strength required for long-term clinical performance.

Chapter 7 – Choosing the Right Titanium Medical Forging for Your Application

Whether you’re developing orthopedic implants, dental components, or spinal fixation devices, we work closely with you to ensure each forging delivers the mechanical reliability, biological safety, and dimensional precision your application demands.

⸻• Understand the Implant Function

Is the component intended for load-bearing, articulation, fixation, or support? Forging geometry, material grade, and surface finish should match its functional purpose within the body.

⸻• Define the Anatomical Fit

Ensure the forging can be shaped or machined to match the patient’s anatomy. For components like hip stems or trauma plates, precision curvature and contour compatibility are critical.

Select a forging form that aligns with your machining capabilities—CNC-ready, pre-contoured, or rough-forged depending on your downstream processes.

⸻• Choose the Right Titanium Grade

Use Grade 5 (Ti-6Al-4V) for strength-intensive applications like joint implants; opt for Grade 23 (ELI) for higher purity and improved biocompatibility in dental or trauma implants.

⸻• Consider Surface Treatment Needs

Plan for any coatings, texturing, or anodizing to enhance osseointegration or antibacterial properties. The forging must support your surface engineering strategy.

⸻• Ensure Regulatory Compatibility

Verify that the forging meets standards such as ASTM F136, F67, and ISO 13485, and includes full traceability for global regulatory compliance.

⸻• Balance Cost and Application Value

Choose a forging that meets both your performance expectations and cost objectives—ensuring efficient use of resources without compromising implant safety or reliability.

At Xunyang Titanium, we are committed to helping you choose the right forging—supporting your success with customized, certified, and ready-to-use titanium components engineered for life-critical medical applications.

Chapter 8 – Why Choose Xunyang Titanium for Your Titanium Medical Forgings?

We exclusively use ASTM F136 and F67-compliant titanium, including Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Grade 23), selected for:

• High biocompatibility and mechanical strength

• Third-party material certification and traceability

• Ultra-clean surfaces with controlled grain structure

✅ Ensures patient safety, fatigue resistance, and global regulatory compliance.

Every part is formed through high-pressure closed-die forging, providing:

• Grain flow alignment for superior fatigue performance

• Minimal defects and near-net shape efficiency

• Tolerance control ideal for orthopedic applications

✅ Delivers structural integrity and machining efficiency for critical medical devices.

⸻🎯 3. Application-Specific Forging Design

From hip stems to spinal cages, we customize forging solutions that match:

• Anatomical contours and implant geometries

• Tolerance levels required for CNC or EDM machining

• Integration with downstream coating or texturing processes

✅ Supports your product development needs with design flexibility and speed.

⸻📊 4. Consistent Quality and Full Traceability

Each forging comes with:

• Material mill certificates (EN10204 3.1 / 3.2)

• Heat treatment logs and batch records

• Dimensional inspection reports (CMM/visual/manual)

✅ Ensures confidence from design through final production.

⸻🧪 5. Verified Performance in Clinical Environments

Our forgings are proven to support:

• High-strength orthopedic load zones

• Long-term biostability in corrosive body environments

• Low rejection and high compatibility rates

✅ Built to withstand real-world surgical and anatomical challenges.

⸻🤝 6. Full-Service OEM & Engineering Support

We go beyond forging by offering:

• Drawing review and implant design assistance

• OEM branding, custom labeling, and export-ready packaging

• Fast turnaround on prototypes and low-MOQ trial orders

• Ongoing technical consultation and after-sales support

✅ A true supply chain partner from concept to delivery.

⸻✅ Why Xunyang Titanium? Because your implant components deserve more than just raw metal—we deliver medical-grade titanium forgings that are precise, customizable, and clinically trusted. Backed by over a decade of titanium experience, we help you bring high-performance medical products to life—safely, efficiently, and reliably.

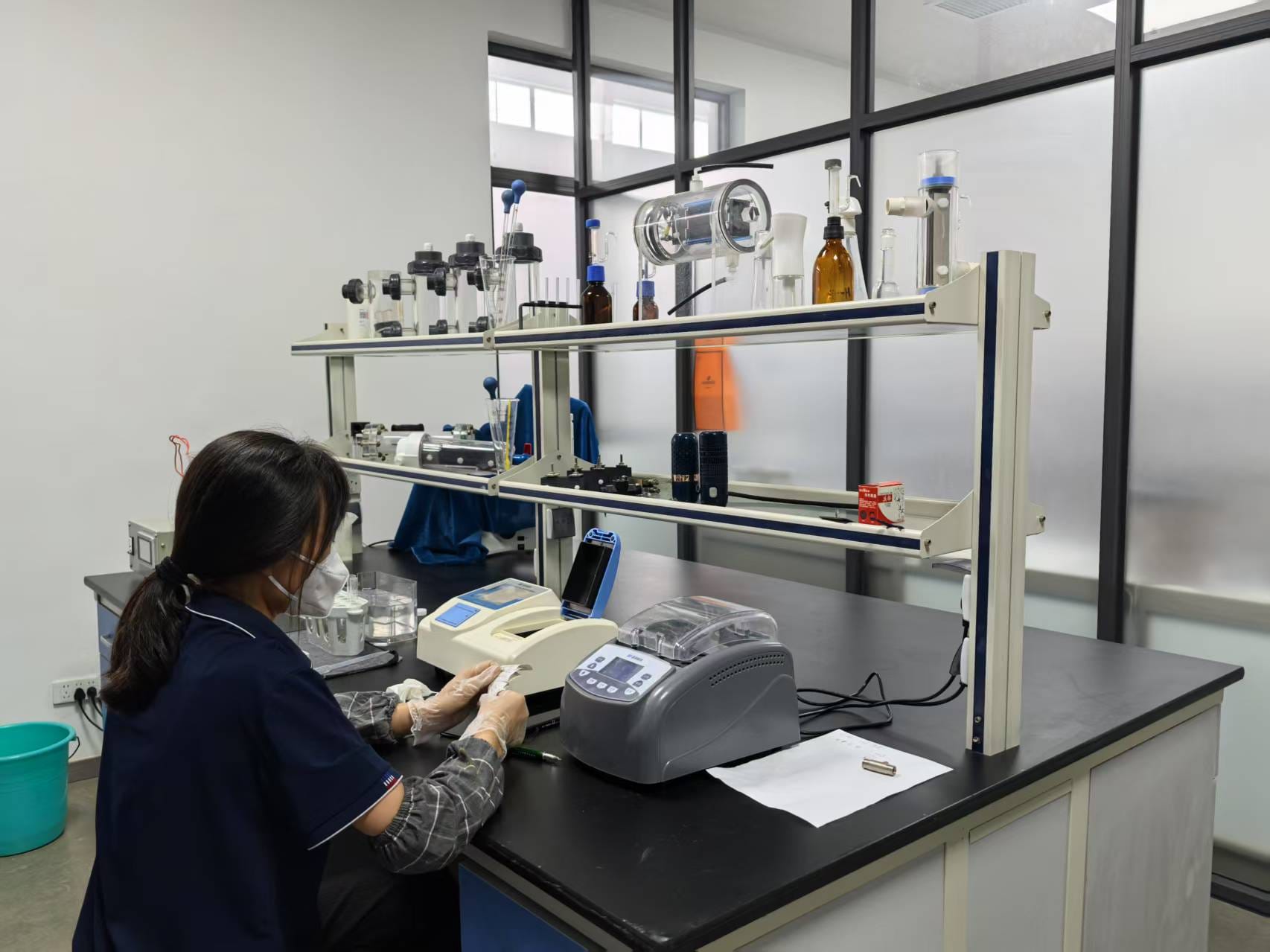

Chapter 9 – How We Ensure the Quality of Titanium Medical Forgings

⸻🔍 1. Certified Materials with Full Traceability

We only use titanium alloys from certified mills, compliant with ASTM F136 (Grade 5) and ASTM F136 ELI (Grade 23) standards. Each batch is recorded with full material test certificates (MTC) and can be traced through the entire production process.

⸻🛠️ 2. In-Process Control During Forging

Our forgings are produced with precision closed-die forging technology, ensuring:

• Controlled grain flow for fatigue resistance

• Stable mechanical properties across the entire lot

• Detailed monitoring of temperature, pressure, and die alignment

All process parameters are logged and reviewed for each batch.

⸻🧪 3. Mechanical & Dimensional Testing

Every batch undergoes key performance tests, including:

• Tensile strength & yield strength verification

• Grain size control (ASTM 5 or finer)

• Hardness testing (HRC 30–36 target)

• Ultrasonic flaw detection

• CMM dimensional checks

• Visual surface inspection

These tests ensure consistency and safety for downstream machining and implant use.

⸻📦 4. Final Quality Review & Packaging

Before shipment, each forging is:

• Inspected for surface defects and dimensional accuracy

• Laser-marked or labeled for full traceability

• Packaged using anti-corrosion and anti-scratch materials

We also offer third-party reports, video inspections, or customer-specified quality checks on request.

⸻At Xunyang Titanium, we don’t just meet the standard—we exceed it. With every forging, we deliver reliability you can trust, and quality you can prove.

• Titanium Substrate: Sourced only from certified TA1/Grade 1 mills; MTC and batch code traceability are retained for every order.

• Precious Metal Coating: Imported iridium and tantalum oxides ensure consistent purity and coating quality.

• Electrochemical Performance Validation: Every batch is tested under simulated working conditions before dispatch.

⸻📦 Packaging & Final Review

Before leaving our facility, each anode is:

• Carefully wrapped with protective material to avoid scratches

• Labeled with batch and QC information

• Double-checked for dimension, coating uniformity, and customer specifications

We also offer inspection videos or third-party test reports upon request for your peace of mind.

⸻At Xunyang Titanium, our commitment to quality goes beyond compliance — it’s about ensuring you receive a product that performs, lasts, and delivers value. Whether for OEM, industrial deployment, or critical applications, you can count on consistent, high-standard anode quality with every order.

Chatper 10 --In Summary

Our forgings are not only engineered to meet the demanding standards of orthopedic, dental, and surgical applications, but also customized to match your exact design and regulatory needs — whether in terms of geometry, grade, grain structure, or surface condition. With rigorous quality control, certified medical-grade materials, and expert engineering support, we strive to deliver components that bring peace of mind — both on the operating table and in your supply chain.

If you’re looking for a partner who values quality, consistency, and long-term cooperation, Xunyang Titanium is here to support you with proven solutions in titanium medical forgings — built for performance, built for life.

Common Questions About Titanium Medical Forgings

Clear Answers. Confident Decisions

Custom Titanium Medical Forgings Made Simple

At Xunyang Titanium, we make sourcing custom titanium medical forgings straightforward and efficient—ideal for orthopedic, trauma, dental, and surgical applications.

⸻1. Submit Your Requirements

Send us your drawings or specs, including titanium grade (e.g. ASTM F136/F67), dimensions, surface finish, and application.

⸻2. Get a Tailored Quote Fast

Within 24 hours, we’ll offer a customized solution with price, lead time, and quality plan—including material traceability and compliance certificates.

⸻3. Confirm & Start Production

Once approved, we begin forging with medical-grade titanium, using precision dies and ISO-certified processes to meet your exact standards.

➤ Trusted by implant manufacturers worldwide—forging parts that support life.

CONTACT US

Send Your Message

Our team is ready to answer all your questions.