Custom Platinized Titanium Anodes

Ready to elevate your electroplating performance? Xunyang Titanium offers custom-engineered platinized titanium anodes designed to match your exact process requirements. These anodes deliver exceptional conductivity, corrosion resistance, and long service life, making them ideal for high-precision electrochemical applications.

Your Trusted Supplier of Platinized Titanium Anodes

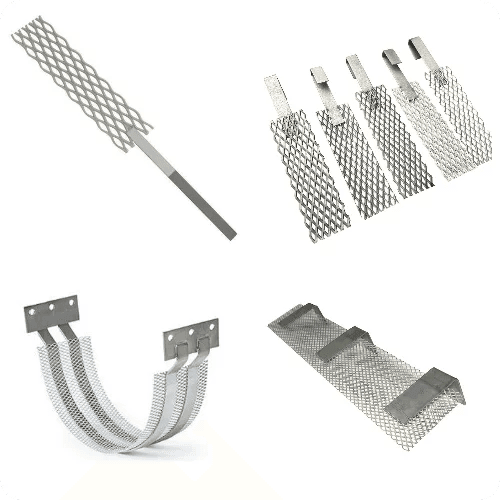

We provide custom-built solutions in various forms including plates, meshes, rods, wires, and tubes—each tailored to meet the needs of applications such as electroplating, precious metal refining, semiconductor processing, and chemical production. At Xunyang, every anode is engineered for consistent output, low maintenance, and maximum value over time.

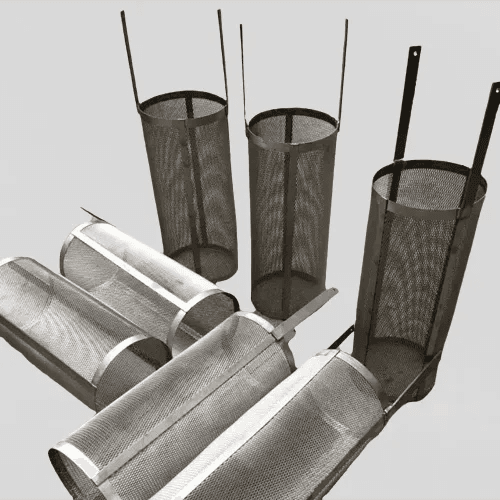

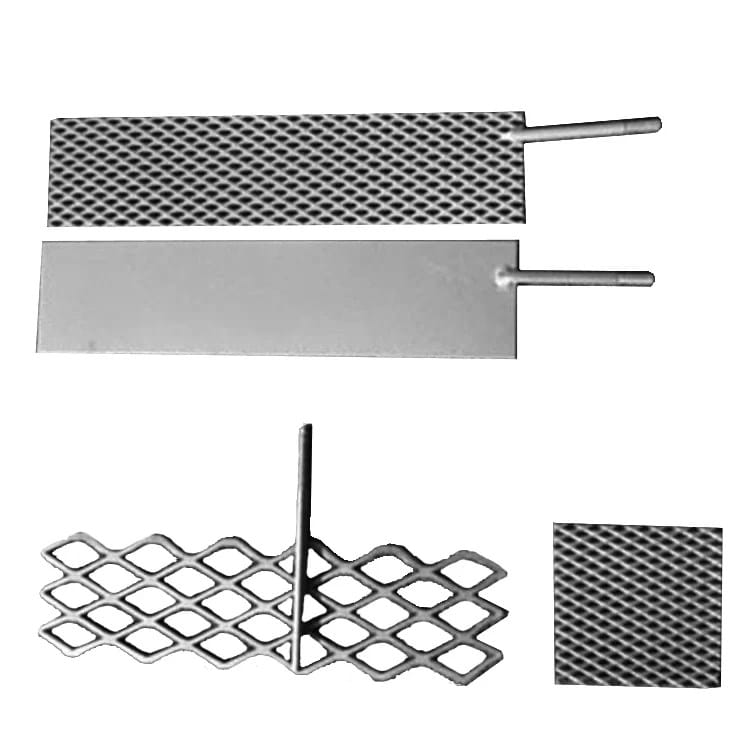

Platinized Titanium Electrodes

Engineered for industrial-grade performance, these electrodes offer excellent conductivity and corrosion resistance, making them ideal for electroplating, fuel cells, and wastewater treatment. Built for stability and long-term use.

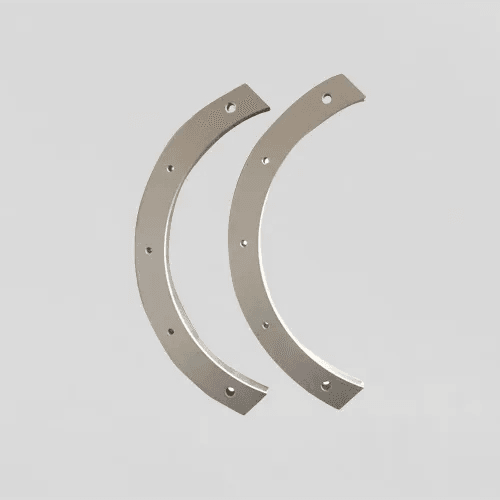

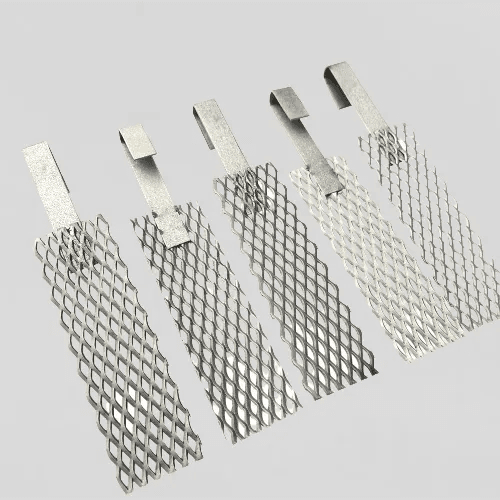

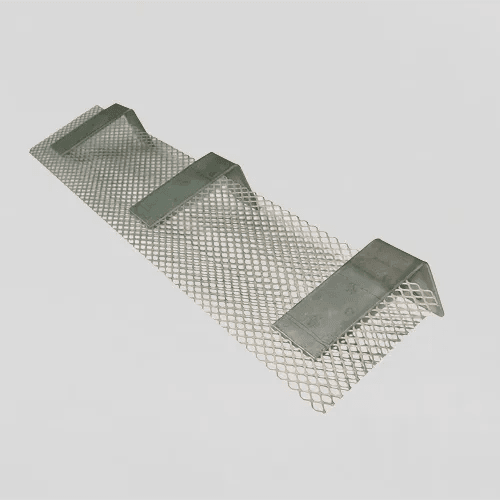

Platinum-Plated Titanium Mesh Anode

Designed for high-surface-area applications, this mesh anode delivers excellent current distribution and is ideal for precise electroplating in complex environments. Durable and corrosion-resistant for continuous industrial use.

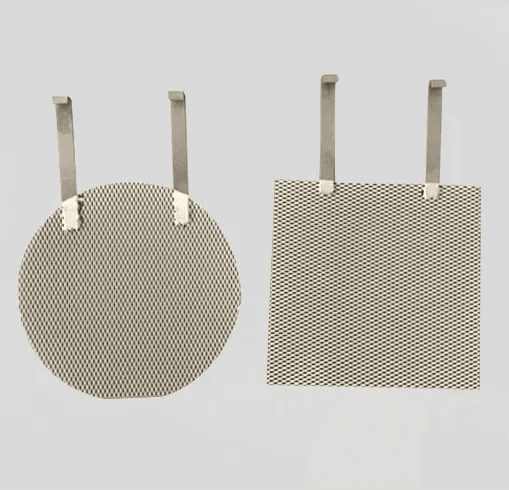

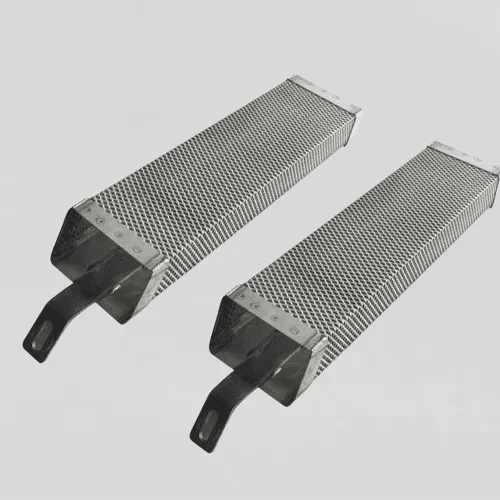

Platinum-Titanium Anode Sheet

Engineered for stable electrolytic performance, this flat-sheet anode provides reliable conductivity and is suitable for precious metal recovery, wastewater treatment, and electrosynthesis.

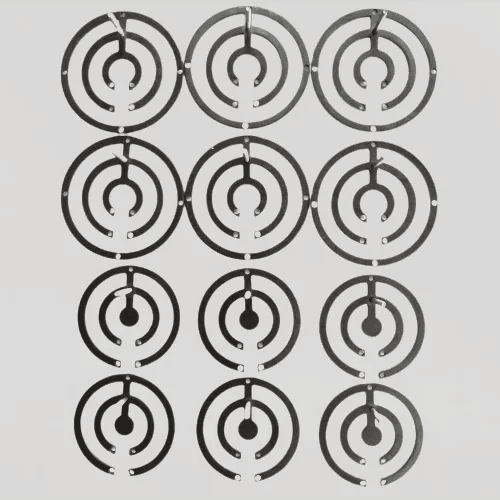

General-Purpose Platinum Titanium Anode

Versatile and long-lasting, this electrode suits a wide range of electrochemical applications, offering balanced performance and excellent resistance to acidic or oxidizing environments.

Platinum-Coated Titanium Rod Anode

Ideal for vertical cell designs, this rod-style anode ensures uniform current flow and durable service in galvanic and electroplating systems. Fully customizable to your system layout.

Platinum-Plated Titanium Anode

Built for performance, this anode offers high conductivity and corrosion resistance. Suitable for electrolysis, chlor-alkali, and plating industries, it’s a dependable solution for continuous operations.

Platinized Titanium Mesh Electrode

With a large active surface area and excellent chemical durability, this mesh electrode excels in high-efficiency electroplating and fuel cell support structures.

Standard Platinized Titanium Anode

A reliable choice for general industrial use, this anode provides a balance of cost-effectiveness and premium performance, making it ideal for routine plating and electrolysis tasks.

Tailor-Made Platinized Titanium Anodes for Your Projects

We manufacture anodes in plates, meshes, rods, wires, or tubes, all tailored to fit your system layout and performance needs.

• Application-Specific Configurations

Whether you’re working in electroplating, fuel cells, or wastewater treatment, we provide the ideal anode form and specifications to ensure optimal results.

• Adjustable Electrical Parameters

Voltage, current density, and surface area can be configured based on your operational conditions to ensure maximum efficiency and durability.

• Precision Platinum Coating

Customize platinum layer thickness to match your process demands—balancing cost, conductivity, and service life.

At Xunyang, we go beyond manufacturing—we partner with you to create high-performance anode solutions that align perfectly with your project goals. Get in touch today to explore custom options that bring precision and value to your operations.

Streamline Your Custom Platinised Titanium Anodes Order with Xunyang Titanium

01.

1. Understand Your Process

We start by analyzing key operational data—electrolyte composition, temperature, current density, voltage, overpotential, and expected anode lifespan.

02.

2. Define the Application

Tell us your target application—electrowinning, electroplating, wastewater treatment, disinfection, or cathodic protection—so we can recommend the optimal anode structure and coating.

03.

3. Select the Reaction Type

Choose the anodic reaction type required for your system: oxygen evolution, chlorine evolution, mixed gas evolution, or oxidation reactions.

04.

4. Submit Your Anode Design

Provide drawings or technical specifications—shape, size, thickness, or connection method. We’ll tailor the final anode to perfectly match your operational needs.

Why Choose Xunyang Titanium for Platinised Titanium Anodes?

Flexible Order Quantities

Whether you need a single prototype or 10,000+ units, we offer scalable ordering options to suit projects of any size.

Veteran Engineering Team

Our technical experts bring over a decade of hands-on experience in MMO and DSA anode fabrication and coating processes.

Competitive Pricing

We provide a smart balance of cost-efficiency and quality, helping you stay competitive without sacrificing performance.

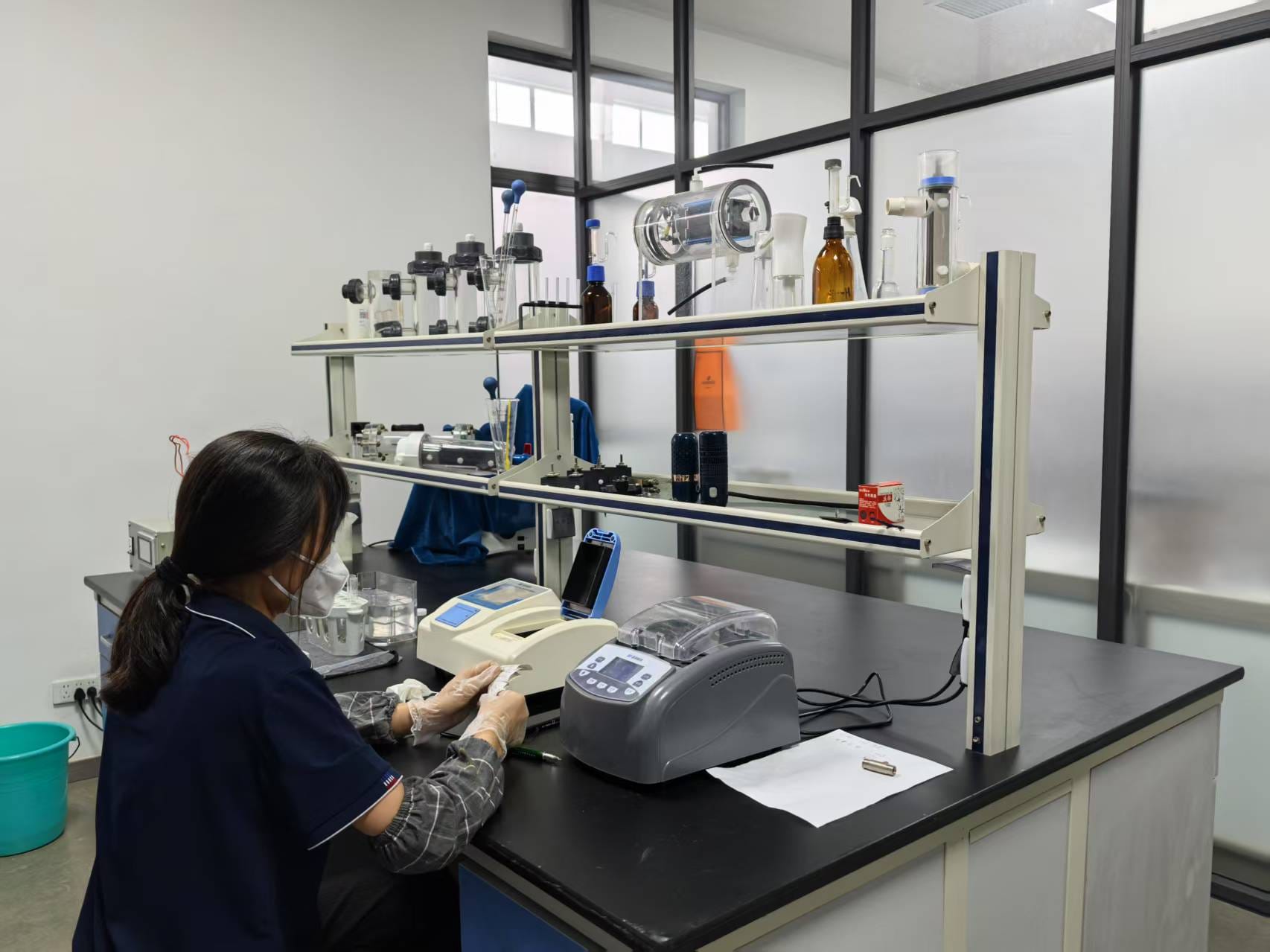

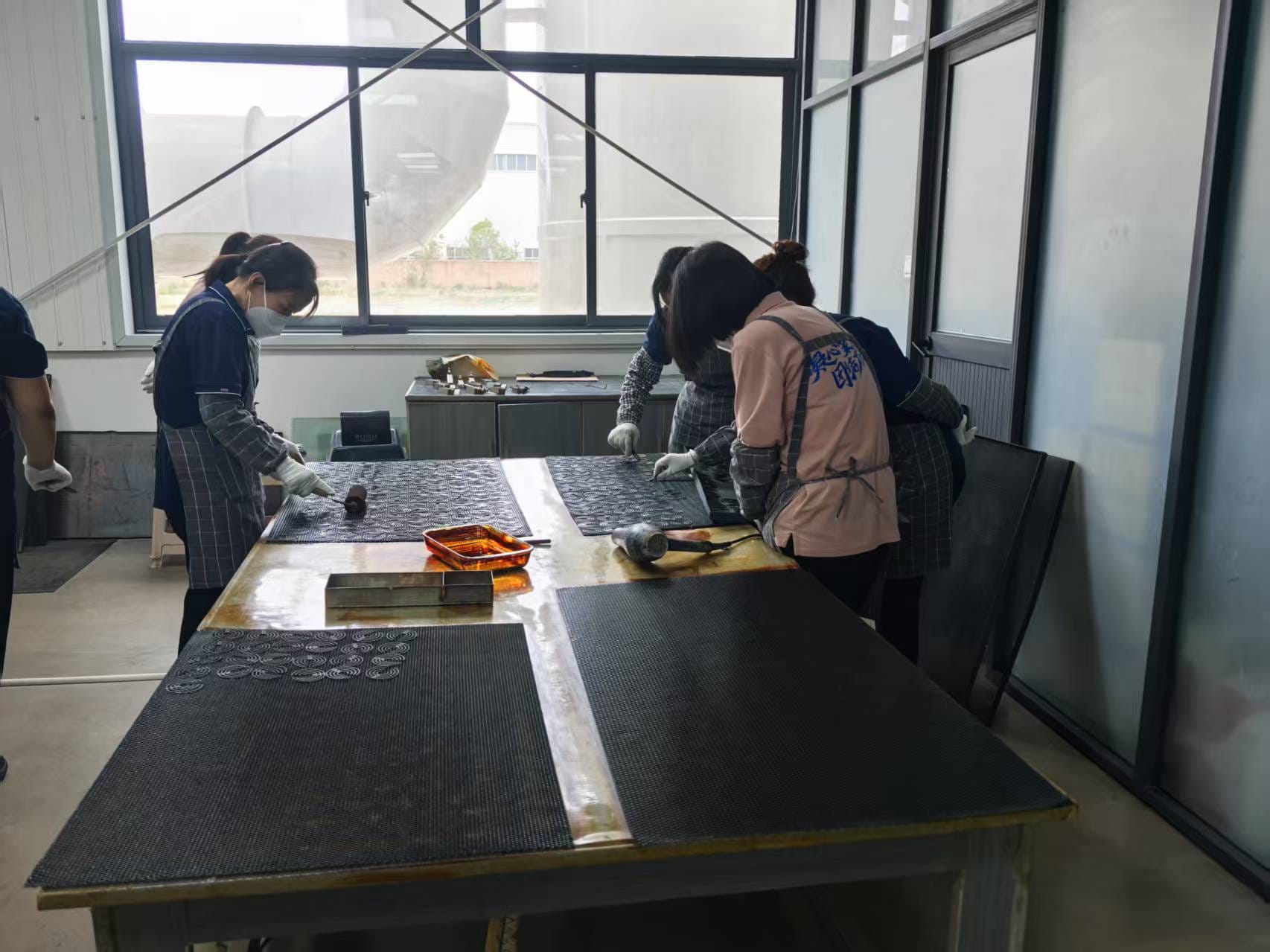

Full-Service Production

From substrate prep to coating and quality testing, we manage every stage in-house to ensure strict process control.

Efficient Lead Times

Our streamlined operations and responsive production workflow ensure fast and dependable delivery worldwide.

Quality You Can Trust

Certified under ISO9001, we guarantee consistent product performance, backed by clear communication and traceable documentation.

Your Complete Guide to Sourcing Platinized Titanium Anodes

This guide highlights the versatility and reliability of platinum-coated titanium anodes in a wide range of industries—including ionized water generators, electrochemical reactors, and energy systems. Whether you’re sourcing for a specific project or planning bulk procurement, this resource will help you identify the right anode solution—engineered for efficiency, corrosion resistance, and long-term value.

Table of Contents

Chatper 1 --What Are Platinized Titanium Anodes?

Widely used in electroplating, water treatment, hydrogen production, and other electrolytic processes, these anodes are favored for their stability and long service life. The platinum layer not only improves resistance to harsh chemical environments but also ensures consistent and efficient operation under demanding conditions.

Thanks to these attributes, platinized titanium anodes are indispensable in industries that demand precision, durability, and high electrochemical efficiency.

Chapter 2 –Advantages of Platinized Titanium Anodes

• Cost-Efficient Platinum Performance

Achieve platinum-level electrochemical performance at a fraction of the cost, thanks to a thin, optimized platinum coating on a reusable titanium base.

• High Electrochemical Efficiency

Offers low overpotential for hydrogen evolution and high overpotential for oxygen evolution, enabling greater process efficiency in electrolysis and plating applications.

• Recyclable Titanium Substrate

Once the platinum layer is depleted, the titanium base can be recoated and reused, promoting sustainability and reducing long-term costs.

Engineered to handle intense workloads and continuous operation, these anodes support high throughput without compromising stability.

• Stable and Uniform Conductivity

Delivers consistent current distribution and is ideal for use in Dimensionally Stable Anode (DSA) applications where reliability is critical.

⸻Thanks to these advantages, platinized titanium anodes are trusted across industries such as electroplating, water treatment, fuel cell production, and chemical synthesis—offering a reliable, long-lasting, and cost-effective solution for demanding electrochemical environments.

Chapter 3 –Tailor-Made Platinized Titanium Anodes for Your Needs

Experience precision manufacturing and application-specific performance, crafted to match the unique challenges of your electrochemical processes.

Our anodes can be manufactured in a wide variety of geometries to meet specific process requirements. Whether your system needs solid, expanded, or perforated structures, we deliver components built for compatibility and efficiency.

Available Forms Include:

• Rods: 10mm–50mm diameter – designed for strength in vertical assemblies.

• Wires: 0.5mm–10mm diameter – ideal for fine conductive pathways.

• Tubes: 10mm–200mm diameter – for structural stability and internal flow applications.

• Plates: 0.5mm–5mm thickness – optimal for surface-area-critical reactions.

• Meshes: 0.5mm–2.0mm thickness – enables high flow-through and conductivity in filtration and treatment systems.

Each dimension and shape is carefully produced to meet the exact technical parameters of your application. From PCB etching to water disinfection systems, Xunyang’s precision-tailored titanium anodes enhance operational performance, durability, and service efficiency.

Choose custom-crafted anodes from Xunyang Titanium to ensure your solution is not only effective—but also built for long-term success.

Chatper 4 --Application of Platinized Titanium Anodes

Widely used in ionized water systems, these anodes efficiently adjust pH levels and enhance oxidation-reduction potential (ORP), making them ideal for healthcare, food processing, and industrial cleaning applications.

Recommended Spec:

• Type: Mesh or perforated sheet

• Coating Thickness: 1.0–2.0 μm

• Current Density: ≤1000 A/m²

Tips: Choose expanded or corrugated mesh to increase contact surface. Confirm compatibility with water pH range and ORP control needs.

In water electrolysis, platinized anodes provide stable catalytic performance for efficient hydrogen production, supporting fuel cells, renewable energy systems, and on-site gas generation units.

Recommended Spec:

• Type: Plate or rod

• Coating Thickness: 1.5–3.0 μm

• Current Density: 1000–3000 A/m²

Tips: Use thicker platinum coating for long-term operation. Request anodes with high-temperature tolerance for >80°C environments.

Their uniform current distribution and high catalytic activity make them perfect for achieving smooth, high-quality metal finishes in electronics, jewelry, and precision components.

Recommended Spec:

• Type: Plate, mesh, or wire

• Coating Thickness: 0.5–2.0 μm

• Current Density: ≤1500 A/m²

Tips: For precious metal plating, ensure uniform coating thickness. Choose mesh when plating uneven or complex parts.

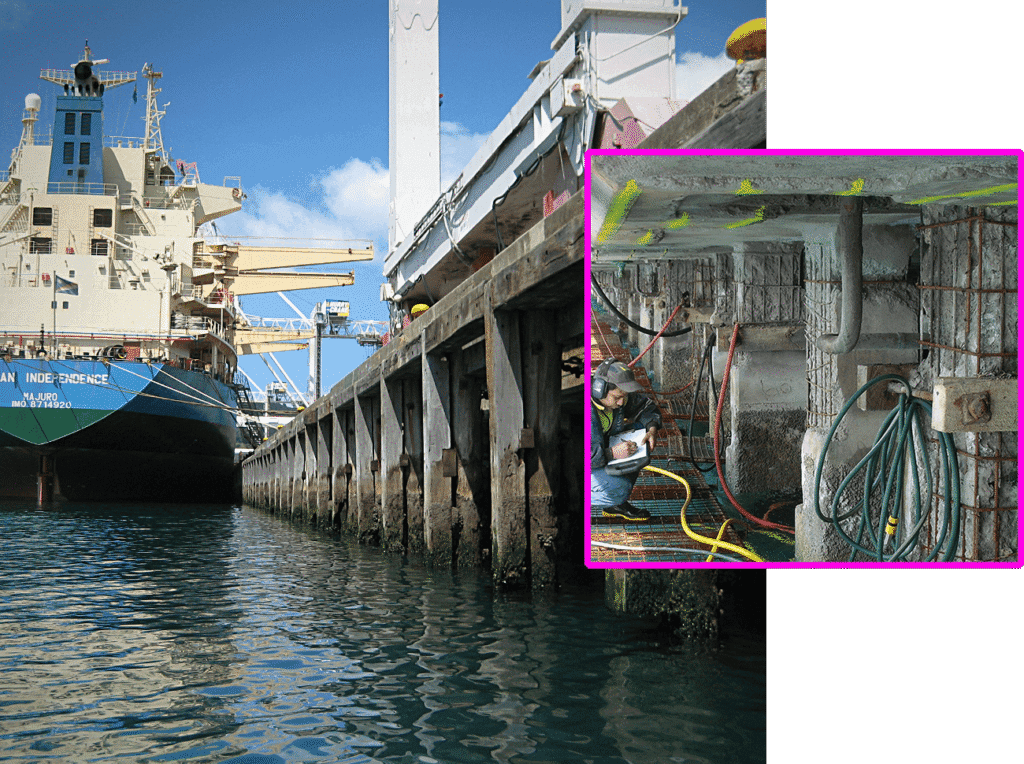

These anodes protect structures like offshore platforms, pipelines, and storage tanks from corrosion, offering low maintenance and long service life in aggressive environments.

Recommended Spec:

• Type: Rod, tubular, or wire

• Coating Thickness: 2.0–5.0 μm

• Current Density: ≤500 A/m²

Tips: Use tubular or rod forms for buried or submerged systems. Request marine-grade titanium for offshore use.

Used in the electro-synthesis of APIs and fine chemicals, platinized anodes ensure precise reaction control and purity, critical for the pharmaceutical industry.

Recommended Spec:

• Type: Disc or small flat plate

• Coating Thickness: 1.0–1.5 μm

• Current Density: 500–1000 A/m²

Tips: Prioritize coating purity and ensure low metal leaching. Consider custom micro-anodes for compact cells.

Ideal for research and development, these anodes provide reliable, repeatable results in academic, industrial, and materials testing labs.

Recommended Spec:

• Type: Foil, wire, or mini plates

• Coating Thickness: 0.2–0.5 μm

• Current Density: Adjustable (by experiment)

Tips: Order in small quantities or sample sets. Look for quick-connect terminals or standardized electrode holders.

Chapter 5 –Best Practices for Use Guidelines for Platinized Titanium Anodes

By following the guidelines below, users can prevent premature failure and maintain efficient operation in industrial electrochemical systems.

• Avoid Surface Damage

Do not use sharp or hard tools that may scratch or chip the platinum layer. Surface damage can compromise conductivity and shorten electrode lifespan.

• Check Electrolyte Compatibility

Ensure the electrolyte does not contain fluoride, bromide, or cyanide ions, as these substances can degrade the coating and cause short-circuiting.

• Control Current Density

Operate within the recommended current density range. Excessively high currents accelerate electrode wear and may lead to failure.

When initiating the system, increase current gradually to avoid thermal or mechanical stress on the coating.

• Ensure Stable Power Supply

Use a regulated power source to avoid voltage or current spikes, which can damage the electrode and reduce efficiency.

• Routine Cleaning and Storage

After each use, rinse thoroughly with clean water, dry completely, and store in a dry, ventilated area away from corrosive gases.

• Avoid Long-Term Overload

Prolonged exposure to high current beyond design limits can reduce electrode life and increase operational risk.

⸻At Xunyang Titanium, safety and product integrity are at the heart of everything we deliver. Our platinized titanium anodes are manufactured under strict quality control to meet the highest performance and safety standards.

Have questions about safe usage? Our technical team is ready to assist with application guidance and operational support. Contact us today to learn more about our products and solutions for your electrochemical systems.

Chatper 6 --Technical Specifications of Platinized Titanium Anodes

| Parameter | Specification |

|---|---|

| Base Material | Grade 1 or Grade 2 Titanium |

| Coating Material | Platinum (Pt) |

| Operating Temperature | ≤ 80°C |

| Current Density | ≤ 5,000 A/m² |

| Max Fluoride Tolerance | ≤ 50 mg/L |

| Platinum Loading | ≥ 20 g/m² |

| Coating Thickness | 0.2–10 μm |

| pH Compatibility | pH 1–12 |

| Available Forms | Mesh, Plate, Tube, Bar |

Each electrode is manufactured with strict quality controls and is available in custom dimensions based on your system design. Whether you’re scaling up a water treatment project or operating a high-density electrolysis line, these specifications ensure compatibility and durability.

Chatper 7 --Choosing the Right Platinized Titanium Anode for Your Application

• Assess Your Working Conditions

Understand the corrosiveness, temperature, and electrical load the electrode will face. Choosing the correct coating and geometry ensures consistent performance and durability.

• Match with Electrolyte Chemistry

Ensure the anode is compatible with the specific solution (e.g., chloride, sulfate, or acidic media). Proper chemical pairing reduces degradation and maximizes service life.

Accurately calculate your process’s current density to select an electrode that operates efficiently within the required range—avoiding overloading or underperformance.

• Temperature Resistance

Verify that the electrode can perform within your process’s thermal range. Excessive heat can shorten lifespan if not properly accounted for.

• pH Suitability

Choose an electrode formulation tailored to your solution’s pH level. Ru-Ir coatings offer broad compatibility but must be matched to the specific range for optimal results.

• Application Fit

Whether you’re working in electroplating, water treatment, or chlor-alkali production, select an electrode form and coating type designed for that specific purpose.

• Balance Between Cost and Lifespan

Optimize your investment by choosing a model that aligns with both your performance expectations and budget, ensuring maximum value over its operational life.

⸻Xunyang Titanium is committed to helping you make the right choice—delivering electrodes that perform reliably, last longer, and support the success of your electrochemical processes.

Chatper 8 --Why Choose Xunyang Titanium for Your Platinized Titanium Anode?

We exclusively use ASTM Grade 1 (TA1) titanium, recognized for its excellent corrosion resistance and conductivity. Each titanium base undergoes:

• Precision surface preparation for optimal coating adhesion

• Full traceability and third-party material verification

• Zero-defect inspection for clean, uniform surfaces

Our coatings are formulated with high-purity platinum, providing:

• Low overpotential for hydrogen and oxygen evolution

• Excellent chemical stability under acidic or oxidizing conditions

• Uniform layer thickness across the electrode surface

✅ Ideal for electroplating, hydrogen generation, functional water, and high-load applications.

🎯 3. Nano-Level Coating Precision

Each anode is processed through a multi-stage, controlled coating cycle, delivering:

• Even platinum layers from 0.2 to 10 μm

• Consistent catalytic performance

• Minimal risk of cracking, peeling, or pinhole defects

✅ Guarantees long service life and stable performance in harsh environments.

🧩 4. Tailor-Made Engineering for Any Geometry

From mesh, rods, and plates to complex custom shapes, we offer:

• Machining precision within ±0.1 mm tolerance

• Flexible coating thickness based on your voltage/current range

• Compatibility with your electrolyte, pH, and operating temperature

✅ Perfect integration into your equipment and process line.

🧪 5. Verified Durability & Long Lifespan

Our anodes are tested to ensure:

• 300–700 hours of lifespan under high current densities

• Strong adhesion via tape pull and bend tests

• Reliable performance in chlor-alkali, water treatment, and plating systems

✅ Reduces maintenance, downtime, and replacement frequency.

🔧 6. End-to-End Technical and OEM Support

We support you throughout the project with:

• Free pre-sale consultation and application matching

• OEM production, logo printing, and private labeling

• Fast delivery and global shipping

• Remote and on-site technical assistance

✅ One-stop solution backed by over 10 years of titanium expertise.

⸻✅ Why Xunyang?Choose Xunyang Titanium when your application demands more than just a standard anode. We deliver customized, high-precision, and high-performance platinized titanium anodes—built to withstand the toughest conditions and engineered to your exact specifications.

Partner with us to power your electrochemical process with reliability, efficiency, and expert support from start to finish.

Chatper 9 --How We Ensure the Quality of Platinized Titanium Anode?

Comprehensive Testing & Quality Assurance

To guarantee product integrity and operational durability, each electrode is subjected to a series of critical performance tests, covering:

• Adhesion strength

• Coating uniformity

• Thickness accuracy

• Electrochemical efficiency

• Chlorine evolution performance

• Wear resistance

• Service life under stress conditions

Our quality assurance team monitors each batch to ensure compliance with international standards and specific customer requirements.

| Test Item | Test Conditions | Acceptance Criteria |

|---|---|---|

| Adhesion Strength | 3M adhesive tape pull test | No black residue on tape |

| 180° bend on Φ12 mm shaft | No coating peel at bend | |

| Coating Uniformity | X-Ray Fluorescence Spectrometer (XRF) | Variation ≤ 15% |

| Coating Thickness | XRF measurement | 0.1–15 μm |

| Chlorination Potential | 2000 A/m², saturated NaCl, 25 ±2°C | ≤ 1.15 V |

| Chlorine Polarization Rate | 200/2000 A/m², saturated NaCl, 25 ±2°C | ≤ 40 mV |

| Accelerated Lifespan Test | 40000 A/m², 1 mol/L H₂SO₄, 40 ±2°C | ≥ 150 hours (1 μm Pt coating) |

| Weight Loss Under Stress | 20000 A/m², 8 mol/L NaOH, 95 ±2°C, 4h electrolysis | ≤ 10 mg |

• Titanium Substrate: Sourced only from certified TA1/Grade 1 mills; MTC and batch code traceability are retained for every order.

• Precious Metal Coating: Imported iridium and tantalum oxides ensure consistent purity and coating quality.

• Electrochemical Performance Validation: Every batch is tested under simulated working conditions before dispatch.

⸻📦 Packaging & Final Review

Before leaving our facility, each anode is:

• Carefully wrapped with protective material to avoid scratches

• Labeled with batch and QC information

• Double-checked for dimension, coating uniformity, and customer specifications

We also offer inspection videos or third-party test reports upon request for your peace of mind.

⸻At Xunyang Titanium, our commitment to quality goes beyond compliance — it’s about ensuring you receive a product that performs, lasts, and delivers value. Whether for OEM, industrial deployment, or critical applications, you can count on consistent, high-standard anode quality with every order.

Chatper 10 --In Summary

Our anodes are not only manufactured to perform under demanding industrial conditions, but also tailored to match your exact project requirements — from current density and electrolyte compatibility to custom dimensions and coating thickness. Backed by rigorous quality control, premium materials, and technical expertise, we aim to deliver consistent, high-performance products that exceed expectations.

If you’re looking for a dependable partner in your supply chain — one that prioritizes quality, responsiveness, and long-term cooperation — Xunyang Trading is ready to support your success with proven MMO anode solutions.

Common Questions About Platinized Titanium Anodes

Get the Clarity You Need

• Electrolyte type

• Operating voltage and current

• Desired anode lifespan

• Application type (e.g., electroplating, disinfection)

• Preferred shape and dimension

These help the supplier customize and price correctly.

Custom Titanium Anodes Made Simple

At Xunyang Titanium, we simplify the process of sourcing Titanium Anodes. Get started in just three easy steps:

⸻1. Submit Your Project Specifications

Send us your application details, including electrolyte type, operating current density, target lifespan, preferred anode shape (plate, mesh, rod, etc.), and size requirements.

⸻2. Receive a Customized Proposal and Quote

Within 24 hours, we’ll provide a tailored anode solution based on your operational needs, complete with a detailed quotation and lead time estimate.

⸻3. Approve & Begin Production

Upon your confirmation and deposit, our team will start production using advanced coating technology and ensure on-time delivery with quality guaranteed.

⸻Our streamlined process ensures you get high-performance titanium anodes—engineered for reliability, durability, and efficiency in every application.

CONTACT US

Send Your Message

Our team is ready to answer all your questions.