Custom CNC Titanium Parts

Manufactuer In China

Specializing in precision machining for various industries. Our products are made from high-grade titanium, ensuring strength, corrosion resistance, and durability. With advanced CNC equipment and skilled technicians, we deliver reliable, custom titanium components for global clients.

Custom CNC Titanium Machined Parts Manufacturer

Experience craftsmanship elevated to a new standard.

Titanium Brackets

Precision-machined titanium brackets featuring lightweight strength, corrosion resistance, and high durability. Ideal for aerospace, robotics, and high-performance industrial applications.

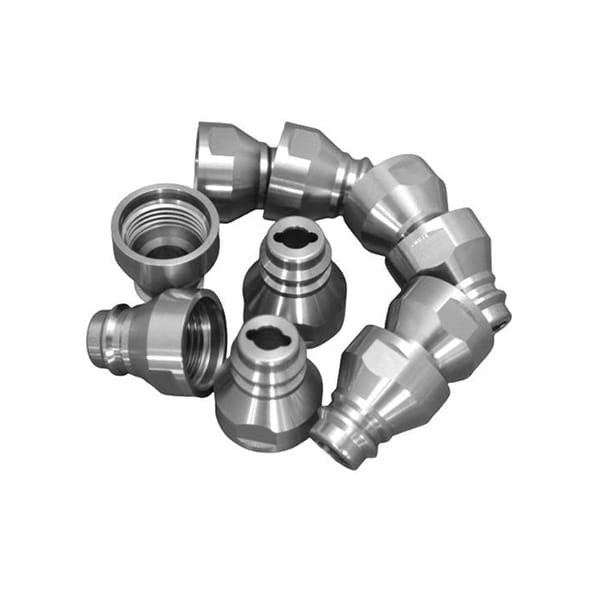

Titanium Connectors

High-precision titanium connectors engineered for lightweight strength, corrosion resistance, and reliable sealing. Ideal for hydraulic, aerospace, and automotive assembly systems.

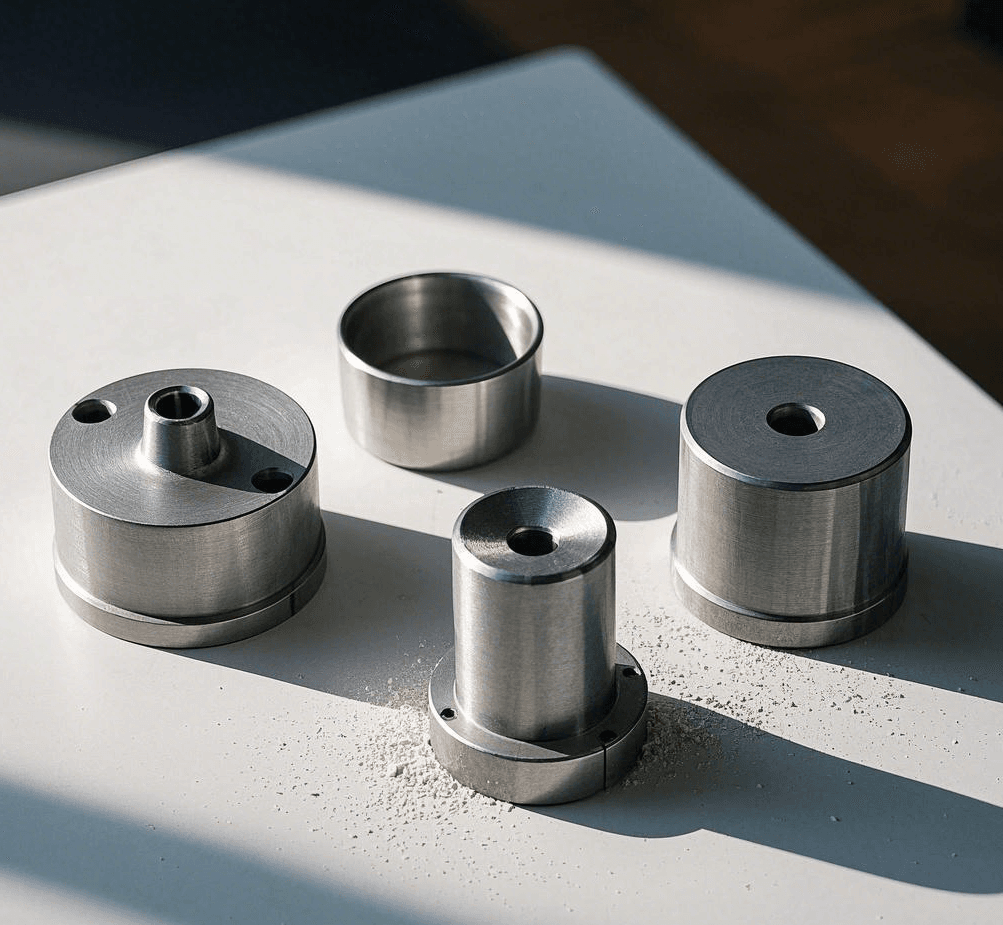

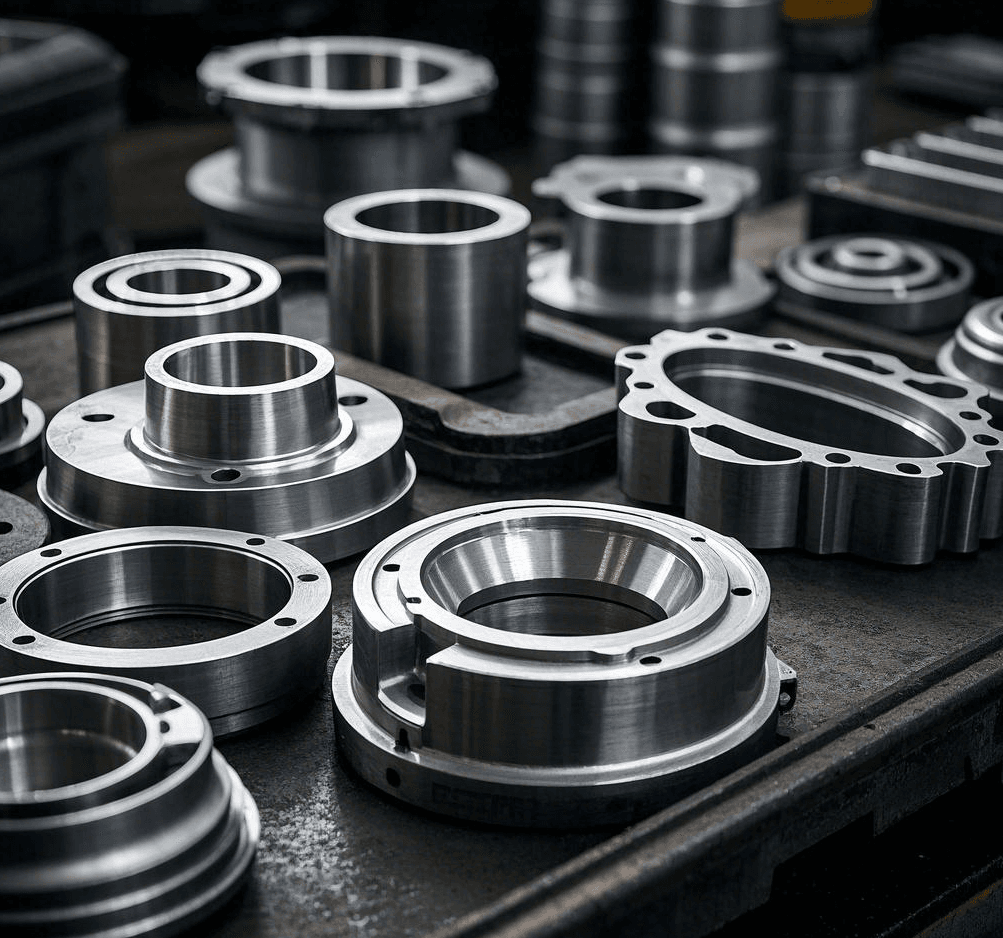

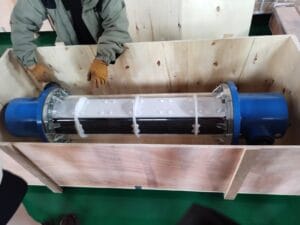

Titanium Housings

High-precision titanium housings engineered for strength, corrosion resistance, and complex internal geometries. Perfect for aerospace, medical, and advanced industrial assemblies.

Titanium Threaded Inserts

Precision CNC-machined titanium inserts designed for secure fastening, lightweight strength, and corrosion resistance. Perfect for aerospace, electronics, and medical assemblies.

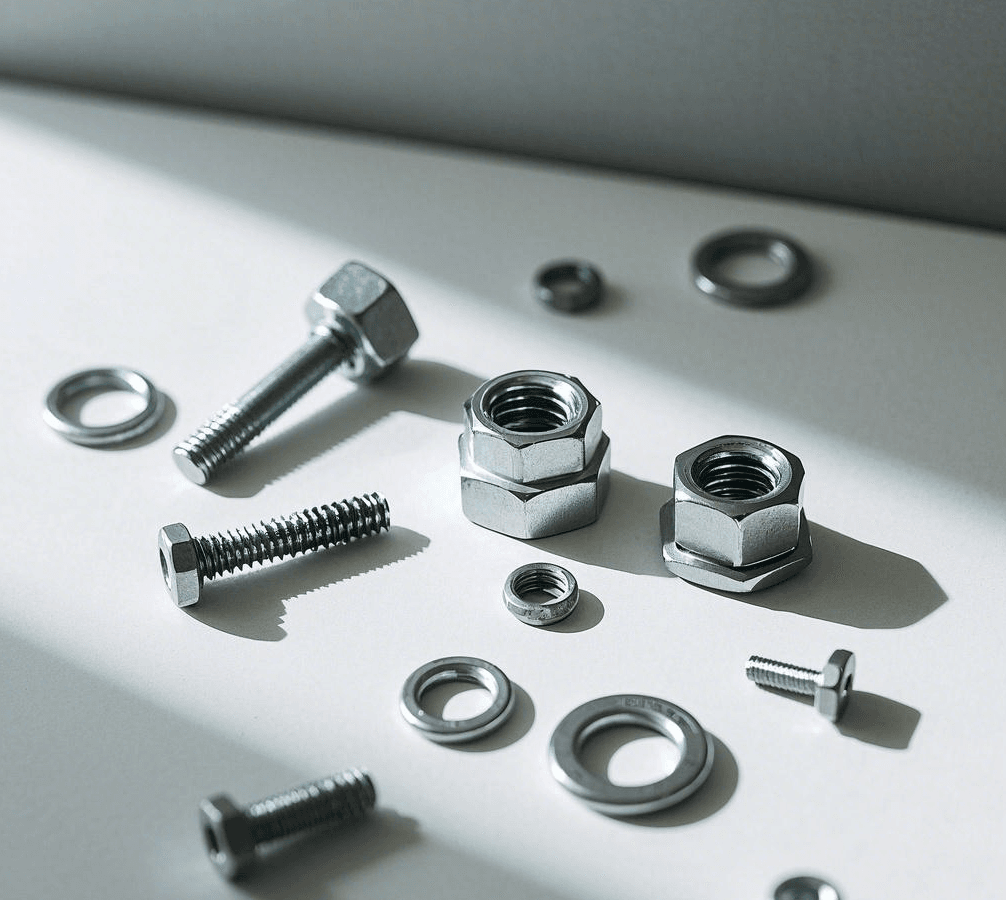

Titanium Precision Bolts

High-strength titanium bolts precision-machined for lightweight performance, corrosion resistance, and reliable fastening. Ideal for aerospace, motorsport, and industrial assemblies.

Titanium Tapered Adapters

Precision-machined titanium tapered adapters for lightweight strength, corrosion resistance, and secure connections. Widely used in aerospace, medical, and high-performance systems.

Titanium Mounting Plates

Lightweight titanium mounting plates precision-machined for complex assemblies, strength, and corrosion resistance. Ideal for aerospace, robotics, and automation systems.

Titanium Alignment Pins & Brackets

Precision-machined titanium alignment pins and brackets for secure positioning, lightweight strength, and corrosion resistance. Ideal for aerospace, robotics, and industrial assembly systems.

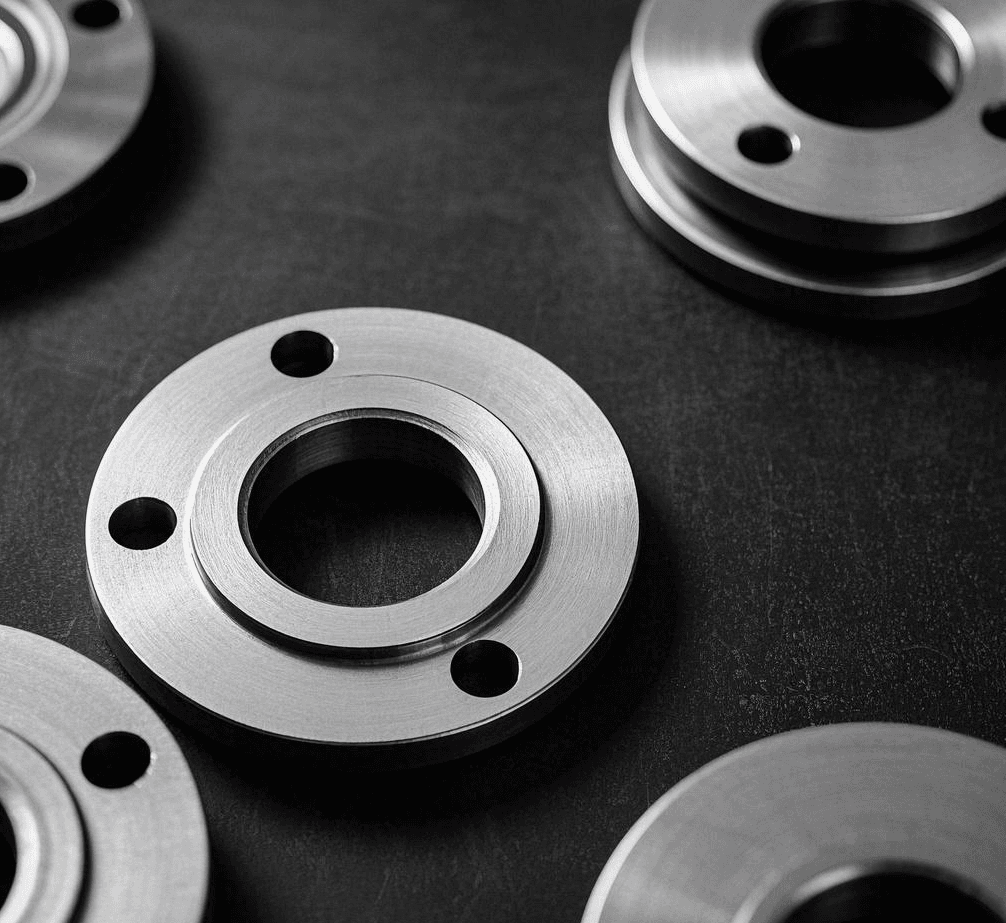

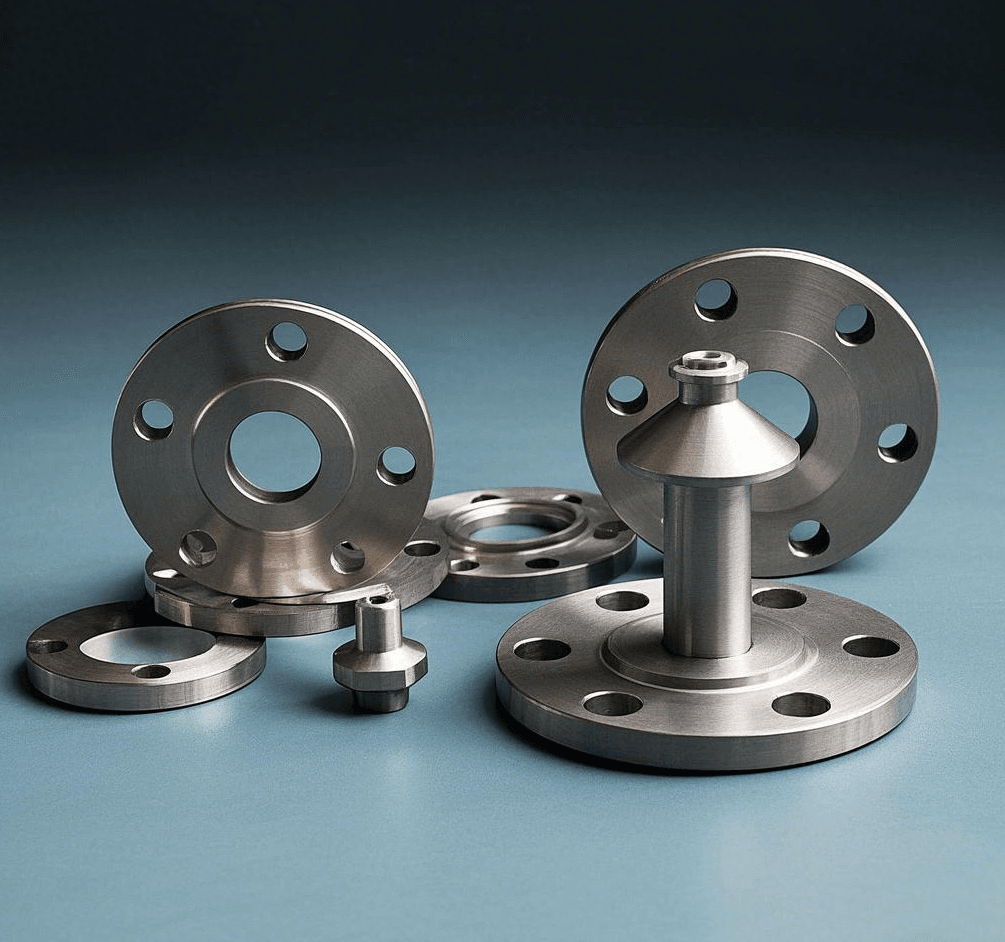

Titanium Clamp Rings

Durable titanium clamp rings precision-machined for lightweight strength, corrosion resistance, and secure holding. Suitable for aerospace, industrial, and medical clamping systems.

Titanium Threaded End Caps

Precision-machined titanium end caps featuring threaded connections for secure sealing, lightweight strength, and corrosion resistance. Ideal for aerospace, hydraulic, and industrial protection systems.

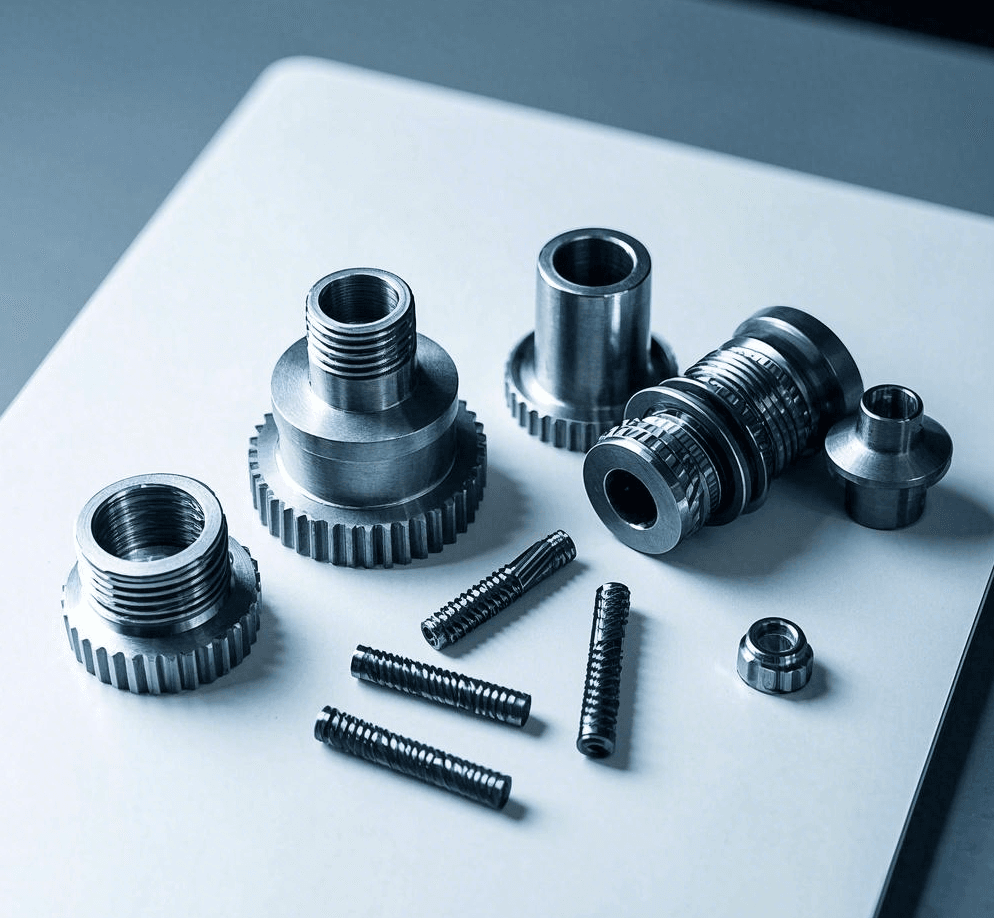

Titanium Customized Parts Set

A versatile set of precision-machined titanium components featuring complex threads, stepped shafts, and tool heads. Engineered for aerospace, medical, and specialized industrial applications.

Titanium Double-Threaded Dowel Pins

Precision-machined titanium dowel pins with double-threaded ends and tool flats for secure positioning and lightweight strength. Perfect for aerospace, industrial fixtures, and automation systems.

Custom Titanium Fasteners – Built to Your Specifications

At NovaFly, we specialize in precision-crafted custom titanium fasteners for industrial, aerospace, medical, and outdoor applications. With years of experience and a professional engineering team, we’re ready to turn your idea into a reliable, ready-to-use solution.

Select from a full range of titanium grades (e.g., Grade 2, Grade 5, Grade 23) to match your environment and performance needs.

• Design Support Our engineers assist with drawings and prototype development, based on CAD or your concept sketch.

• Precision Sizing From micro fasteners to large-dimension components, we manufacture to exact tolerances.

• Thread Types Available in UNC, UNF, Metric, or your custom specification.

• Surface Finishes Options include anodizing, polishing, coating, or others to improve corrosion resistance, durability, and aesthetics.

More Than a CNC Titanium Parts Supplier

01.

Expert Titanium Grade Consultation

Confused between Grade 2, Grade 5, Grade 9, or other titanium alloys? We help you choose the optimal material based on strength, corrosion resistance, machinability, and application environment.

02.

Engineering Support That Moves Projects Forward

From CAD model optimization to feasibility analysis and prototyping, our engineering team offers responsive, professional guidance at every stage of your CNC titanium project.

03.

Broad Capabilities, Custom Results

We produce a wide range of custom-machined titanium components including housings, shafts, adapters, covers, and fasteners for medical, aerospace, marine, and industrial use.

04.

Precision Machining, Professional Finishes

With over 10 years of titanium expertise, we ensure your parts meet exact specs—with surface treatments like anodizing, sandblasting, or polishing available to match your technical and visual standards.

Why Partner with Xunyang for CNC Titanium Parts?

Flexible Order Volumes

Whether you need 1 prototype or 10,000+ production units, we scale to meet your requirements without compromising quality or lead time.

Proven Expertise

Backed by 10+ years of titanium specialization, our skilled team ensures each part meets international standards and tight tolerances.

Competitive Pricing

We provide a smart balance of cost-efficiency and quality, helping you stay competitive without sacrificing performance.

Complete Titanium Machining Solutions

From raw material sourcing to final finishing, we handle the full process in-house—delivering consistent results and simplified logistics.

Reliable Delivery

With streamlined operations and fast turnaround, we deliver on schedule—even for urgent or time-sensitive orders.

Client-Centric Service

We don’t just supply parts—we build partnerships. Expect clear communication, technical support, and responsive service every step of the way.

Your Project’s Precision and Quality Are Our Responsibility

At Xunyang, we understand that every detail matters. That’s why we are committed to delivering high-quality titanium parts that meet your exact specifications—on time and with precision you can trust.

Our titanium components are widely used in industries such as aerospace, medical, automotive, and industrial machinery, where reliability and strength are non-negotiable. From material selection to final inspection, we take full responsibility for your product’s performance and safety.

Why Choose Xunyang Titanium Parts?

- Precision CNC Machining – Achieve micron-level accuracy with advanced equipment and skilled technicians.

- Corrosion Resistance – Ideal for harsh environments and demanding applications.

- Flexible Customization – We adapt to your designs, volumes, and timeline needs

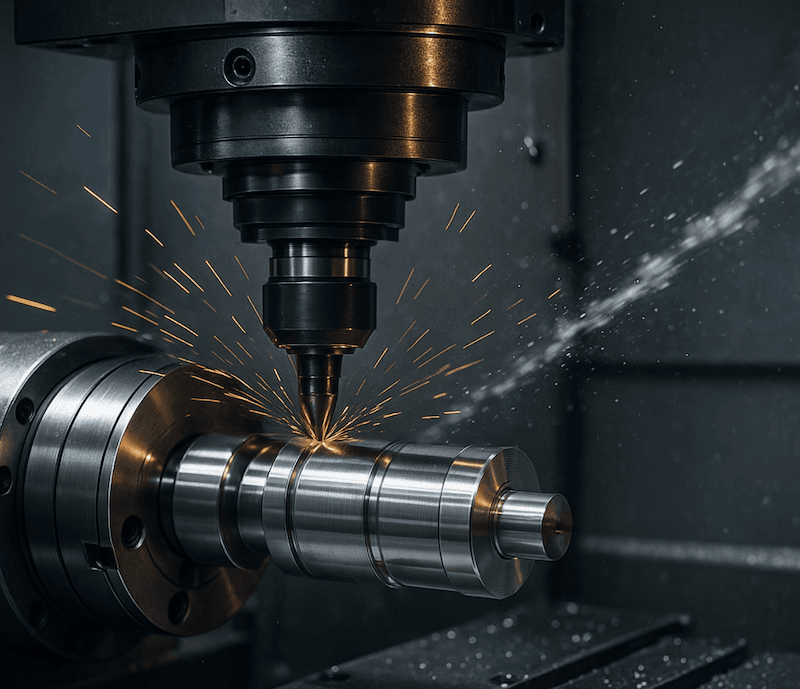

Chatper 1 --What Are CNC Titanium Machined Parts?

They are used to form the core of complex assemblies, enabling precise mechanical function , structural integrity, and long-term durability in demanding environments.

Chatper 2 --Features of CNC Titanium Parts

• High Strength-to-Weight Ratio: Despite being lightweight, titanium offers exceptional mechanical strength, making parts both durable and efficient.

• Superior Corrosion Resistance: Excellent resistance to seawater, acids, and chemicals ensures long-lasting performance in harsh environments.

• Thermal Stability: These parts maintain structural integrity under extreme temperatures, suitable for aerospace, automotive, and high-performance machinery.

• Excellent Surface Finish: CNC processing allows for clean edges, smooth surfaces, and customizable finishes like polishing or anodizing.

• Biocompatibility: Safe for medical and dental applications—titanium parts are non-toxic and body-friendly.

• Wear Resistance: Titanium’s hardness and resistance to deformation extend component life in friction-heavy applications.

• Customizable Designs: CNC machining supports flexible production from simple parts to intricate prototypes based on your CAD models.

Chatper 3 --CNC Titanium Fasteners and Machined Parts Specification

At Xunyang, our CNC titanium fasteners and precision-machined parts deliver exceptional strength, superior corrosion resistance, and precision customization. From aerospace-grade bolts to intricate titanium components, every piece is crafted to meet the highest industry standards. Lightweight, durable, and precision-engineered, our titanium solutions empower your projects with unmatched reliability and performance.

| Content | Description | Specification |

|---|---|---|

| Standards Available | ASTM / ISO / DIN / JIS / AMS | |

| Material | Gr1, Gr2, Gr3, Gr5 (Ti-6Al-4V), Gr7, Gr9, Gr12, Gr23 (Ti-6Al-4V ELI) | |

| Surface Finishes | Polishing, Anodizing, Black Oxide, Sandblasting, Electroplating, Custom Coatings | |

| Component Category | Titanium Bolts | Diameter: M5-M24 / Length: 10mm-300mm (0.39“-11.8”) |

| Titanium Threaded Studs | Diameter: M5-M24 / Length: 10mm-300mm (0.39”-11.8“) | |

| Titanium Washers | OD: 5mm-200mm (0.20“-7.87”) / ID: 1mm-100mm (0.04“-3.94“) / Thickness: 0.1mm-30mm (0.004“-1.18“) | |

| Titanium Screws | Diameter: M5-M24 / Length: 10mm-300mm (0.39”-11.8“) | |

| Titanium Nuts | Size: M3-M22 | |

| Applications (General) | Racing, Motorcycle, Bicycle, Electronics, Medical Equipment, Industry, Ship, Seam Water, Desalination, Marine Engineering, Petroleum, Metallurgy and Chemical, Construction Industry, Outdoor and Artware | |

Chatper 4 --Material Grade of CNC Titanium Machined Parts.

At Xunyang, we utilize a full range of titanium grades—from the ultra-formable Grade 1 to the high-strength aerospace standard Grade 5. Each titanium grade offers distinct advantages in strength, corrosion resistance, machinability, and weight optimization. Our CNC-machined parts are precisely crafted from the right material to ensure maximum performance, reliability, and application-specific excellence.

| Grade | Features | Typical CNC Applications |

|---|---|---|

| Grade 1 | Pure titanium; Highest ductility, excellent corrosion resistance | Chemical tanks, marine hardware, soft pressure vessels |

| Grade 2 | Good strength; Excellent formability and weldability | Medical components, industrial equipment, fittings |

| Grade 3 | Higher strength than Grade 2; Moderate ductility | Aerospace structural parts, industrial bases |

| Grade 5 (Ti-6Al-4V) | Superior strength-to-weight ratio; Most widely used titanium alloy | Aerospace frames, medical implants, high-performance mechanical parts |

| Grade 7 | Excellent corrosion resistance with palladium; High chemical stability | Valves, heat exchangers, chemical processing equipment |

| Grade 9 (Ti-3Al-2.5V) | Good strength and high ductility; Easier to form and weld | Aircraft tubing, sports equipment, lightweight structures |

| Grade 12 | Corrosion resistant with nickel and molybdenum; Good strength | Heat exchangers, marine hardware, industrial piping |

| Grade 23 (Ti-6Al-4V ELI) | Higher toughness and lower impurity; Medical-grade titanium | Surgical components, dental implants, orthopedic devices |

Chatper 5 --CNC Titanium Machined Parts Forms

Xunyang manufactures a wide range of CNC titanium parts tailored to your specific needs—bolts, nuts, washers, studs, pins, threaded rods, anchors, and more. Each form is carefully engineered to deliver lightweight durability, corrosion resistance, and structural integrity across critical applications. From intricate custom components to standard fastening solutions, our titanium parts are shaped for precision and built for demanding environments.

| Component Type | Description | Specification |

|---|---|---|

| Titanium Bolts & Screws | Threaded fasteners joining components; types include hex head, countersunk, cap head. Require mating nuts or threaded holes. | Diameter: M1.6 – M48; Length: 3mm – 300mm; Threads: UNC, UNF, Metric |

| Titanium Nuts | Internally threaded components paired with bolts/screws; types include hex, lock, and wing nuts. | Diameter: M1.6 – M48; Threads: UNC, UNF, Metric |

| Titanium Washers | Flat discs used under bolt heads or nuts to distribute load and prevent loosening. | ID: starts from 1mm; OD: up to 100mm; Thickness: 0.3mm – 12mm |

| Titanium Studs | Fully threaded rods used mainly for flanges, heavy-duty assemblies, or frequent disassembly. | Diameter: M1.6 – M48; Length: 10mm – 500mm; Threads: UNC, UNF, Metric |

| Titanium Pins | Unthreaded cylindrical components for alignment or semi-permanent assembly; types include dowel pins and clevis pins. | Diameter: starts from 1mm; Length: 5mm – 300mm |

| Titanium Threaded Rods | Long rods fully threaded; used in construction, plumbing, and general manufacturing. | Diameter: M2 – M52; Length: up to 3m; Threads: UNC, UNF, Metric |

| Titanium Anchors | Fasteners designed to secure materials to concrete/masonry; types include wedge, drop-in, and sleeve anchors. | Diameter: M3 – M24; Length: 10mm – 200mm |

| Titanium Retaining Rings | Snap rings used to retain components on shafts or inside bores; available in internal and external styles. | Diameter: starts from 3mm; Thickness: 0.5mm – 5mm |

| Titanium Rivets | Permanent mechanical fasteners with a head and tail; used for non-removable joints. | Diameter: 1mm – 8mm; Length: 5mm – 100mm; Head types: flat, round, countersunk |

| Titanium Spacers & Standoffs | Cylindrical components used to separate PCBs, assemblies; available in unthreaded or threaded forms. | Diameter: starts from 2mm; Length: 2mm – 250mm; Threads (if applicable): UNC, UNF, Metric |

Chatper 6 --CNC Titanium VS Stainless Steel Machined Parts

CNC titanium machined parts and CNC stainless steel machined parts each offer unique strengths. Titanium parts deliver lightweight performance, superior corrosion resistance, and exceptional biocompatibility, ideal for aerospace, medical, and high-performance applications. Stainless steel parts offer outstanding absolute strength, cost-efficiency, and widespread versatility, making them a trusted choice across industrial sectors. At Xunyang, we help you select the optimal material to match your project’s performance, weight, and budget needs.

| Property | CNC Titanium Machined Parts | CNC Stainless Steel Machined Parts |

|---|---|---|

| Weight | Much lighter, ideal for applications needing weight reduction | Heavier, adds to structural stability |

| Strength | High strength-to-weight ratio | Very high absolute strength, depending on grade |

| Corrosion Resistance | Exceptional, especially in saltwater, chemicals, and acids | Good, but prone to corrosion without proper grades |

| Biocompatibility | Excellent; widely used for medical implants | Certain stainless steels (like 316L) are biocompatible |

| Temperature Tolerance | Excellent heat resistance, stable under extreme conditions | Good, but can lose strength above 870°C |

| Cost | Higher material and machining cost | More cost-effective and widely available |

| Machinability | More difficult to machine; requires precision tooling | Easier to machine compared to titanium |

| Surface Finish | Naturally appealing, can be anodized for colors | Can achieve mirror polish, brushed, or matte finishes |

| Elasticity | Higher elasticity, returns to original shape under stress | Less elastic, more rigid |

| Magnetism | Non-magnetic (pure grades) | Varies; Austenitic stainless steels are non-magnetic, others are magnetic |

Chatper 7 --Applications of CNC Titanium Machined Parts

• Medical:

Thanks to their biocompatibility and precision, CNC titanium parts are commonly used in surgical instruments, bone plates, dental implants, and orthopedic devices. The non-reactive nature of titanium ensures long-term safety in the human body.

• Automotive: In performance and motorsport vehicles, CNC-machined titanium parts are used in engine components, suspension parts, and exhaust systems. Their heat resistance and light weight contribute to efficiency and speed.

• Sports & Outdoor Equipment:

High-end bicycles, climbing gear, and camping tools benefit from lightweight, durable titanium components that are custom-machined for strength, performance, and design precision.

• Oil & Gas: CNC titanium parts are trusted in subsea valves, pressure housings, and connectors used in corrosive environments like offshore drilling and refineries, ensuring durability and safety.

• Chemical Processing: Equipment in chemical plants often requires non-reactive, precision-engineered titanium parts that can resist strong acids, solvents, and extreme processing conditions.

• Construction & Architecture: Titanium is used in structural anchors, facade elements, and custom fittings for coastal and iconic buildings, offering both aesthetic appeal and corrosion protection.

• Consumer Electronics: Lightweight and strong, titanium components are used in premium electronics such as smartphones, smartwatches, and audio devices—offering durability without adding bulk. • Defense & Military CNC titanium parts are integral to armor systems, drones, submarines, and tactical equipment, where strength, stealth, and resistance to extreme environments are non-negotiable.

⸻These applications highlight how CNC titanium machined parts serve as critical elements in advanced engineering, combining functional reliability with cutting-edge performance across industries.

Chatper 8 --Custom Surface Finishing Options for CNC Titanium Machined Parts

Our polishing service enhances the appearance and smoothness of titanium parts. This process removes micro-imperfections, delivering a clean, bright, and reflective finish—ideal for medical, consumer, and high-end industrial components where surface aesthetics matter.

Anodizing Finish

Anodizing creates a durable oxide layer on the titanium surface, improving corrosion resistance and wear durability. It also allows for color customization, making it popular in aerospace, medical, and lifestyle product applications where identification or branding is important.

For applications requiring a low-reflection, matte black surface, our black oxide treatment offers a functional and visually appealing solution. It also provides moderate corrosion resistance and is often used in tactical or precision equipment.

Color Plating Finish

Color plating gives your titanium parts a distinct, decorative surface by adding a thin metallic coating. This method not only enhances appearance and scratch resistance but also improves part differentiation in complex assemblies or consumer-facing products.

With our diverse

finishing capabilities, Xunyang ensures that your CNC titanium components not only meet structural specifications but also align with design, branding, and environmental requirements. Whether you need aerospace-grade protection or a showroom-ready finish, we can deliver.

Chatper 9 --How to Choose a Reliable CNC Titanium Machining Parts Manufacturer?

Start by searching online for CNC machining companies that specialize in titanium. Prioritize manufacturers with strong customer feedback, detailed project case studies, and a proven track record in your industry.

✅ Verify Technical Certifications

A reliable CNC machining supplier will hold relevant quality certifications such as ISO 9001, AS9100, or medical-grade compliance (ISO 13485)—depending on your application. These validate their process consistency and quality assurance systems.

Ask the shortlisted suppliers for customer references, especially in your target industry. Speaking with past or current clients gives insight into the supplier’s service, consistency, and delivery performance.

✅ Inspect Manufacturing Facilities

If possible, visit the manufacturer’s facility or request a virtual tour. This allows you to assess CNC equipment capabilities, material handling procedures, and quality control processes firsthand.

✅ Review Sample Work

Always request sample components before placing a full order. This helps verify machining accuracy, surface finish quality, and tolerance control for your specific part geometry.

✅ Check Customization Capabilities

A skilled titanium machining partner should support custom design, CAD drawing execution, multi-axis machining, and surface treatment options such as anodizing or polishing.

✅ Evaluate Communication & Responsiveness

A reliable manufacturer communicates clearly, responds promptly, and keeps you updated throughout the process. Efficient communication is essential for complex, high-value projects.

✅ Assess Lead Times and Production Capacity

Make sure the supplier can meet your project timelines and handle both low-volume prototyping and high-volume production as needed. Scalability is key for long-term partnerships.

✅ Understand Pricing and Terms

Request detailed quotes, including material sourcing, machining, finishing, and logistics. Confirm payment terms, potential bulk discounts, and cost transparency to avoid surprises later.

✅ Consider After-Sales Support

Professional CNC part suppliers provide post-shipment assistance, including dimensional inspection reports, warranty options, and rework or replacement policies if needed.

Chatper 10 --In Summary

With over a decade of experience in titanium machining, Xunyang delivers high-precision CNC titanium components that meet the demanding requirements of aerospace, medical, marine, and industrial applications. We offer a wide range of titanium grades, machining capabilities, surface finishes, and tight-tolerance specifications—all tailored to your design and function needs. Our expert team handles everything from prototypes to large-volume production and can replicate or improve upon custom samples provided by our clients.

When it comes to reliable, high-performance titanium machined parts, Xunyang is your trusted manufacturing partner.

Common Inquiries

Your Questions Answered

• Gr5 (Ti-6Al-4V) is the most widely used, offering an excellent balance of strength, weight, and corrosion resistance — suitable for aerospace, automotive, and medical industries.

• Gr2 is preferred for applications needing excellent corrosion resistance with moderate strength, such as marine or chemical equipment.

• Gr23 is the medical-grade version of Gr5, with improved toughness and biocompatibility.

Selection Tip: Choose based on mechanical strength, corrosion environment, and machinability required for your part.

For high-precision applications (such as aerospace, medical implants, optical devices), we can offer up to ±0.01mm, depending on part geometry and material stability.

Note: Tighter tolerances may increase machining cost and lead time slightly, but they ensure better assembly compatibility and performance.

• Polishing: Smooth, shiny appearance, lower friction.

• Anodizing: Enhanced corrosion resistance, optional color coding.

• Sandblasting: Matte texture for better grip and aesthetic purposes.

• Black Oxide: Non-reflective black finish, moderate corrosion protection.

• Custom coatings (e.g., PTFE, PVD) are available upon request.

Impact: Surface finish affects not just appearance but also corrosion resistance, wear resistance, and functional behavior (especially in mating or moving parts).

• Small to Medium Batch Production: 15–25 working days depending on complexity and quantity.

• Large Orders: 30+ working days, with delivery milestones if needed.

Note: Lead times can be optimized based on order urgency — express production services are available with additional cost.

• Dimensional Inspection Reports including CMM (Coordinate Measuring Machine) test results for critical dimensions.

• Surface Roughness Test if required.

• Tensile Test, Hardness Test, and Ultrasonic Testing (UT) for critical aerospace or medical components.

• ISO 9001 and AS9100 quality systems compliance at manufacturing facilities. Conclusion: Full traceability and inspection ensure parts meet not only dimensional but also mechanical and safety standards.

Custom CNC Titanium Machined Parts Made Easy!

CNC Titanium Parts: Precision Solutions Simplified

At Xunyang, we make sourcing CNC titanium machined parts effortless. Get started today in just 3 simple steps:

1. Share Your Project Requirements

Send us your technical drawings, material specifications, quantity needs, and any special machining or finishing preferences.

2. Receive a Tailored Solution & Quote

Based on your project details, we’ll deliver a customized machining plan and a detailed quotation within 24 hours.

3. Confirm and Start Production

After your approval and deposit confirmation, we will proceed with precision manufacturing and arrange secure, on-time delivery to your location.

Our process is designed to make ordering CNC titanium parts simple, fast, and reliable for industries that demand the highest standards.

CONTACT US

Send Your Message

Our team is ready to answer all your questions.

Insight

How does a sacrificial anode help prevent corrosion?

Watching valuable steel structures like boat hulls or pipelines rust away is a costly problem.

How to be absolutely sure that a metal is really Titanium?

Worried you’ve received fake titanium? Material fraud is a real risk, costing you time and

What materials can be used as an anode and cathode?

Choosing the wrong electrode materials can lead to system failure and wasted costs. Unsure which

Can titanium anode be used in water electrolysis?

Are you exploring materials for water electrolysis and wondering if titanium anodes are suitable? The