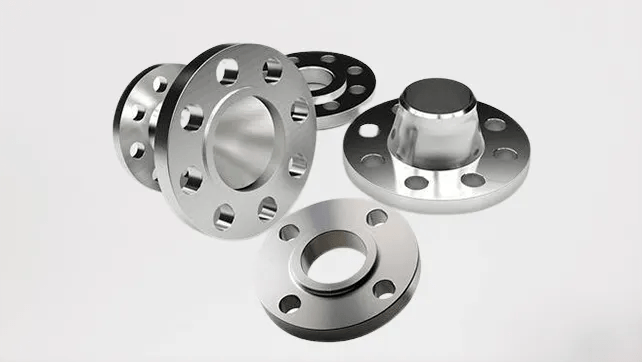

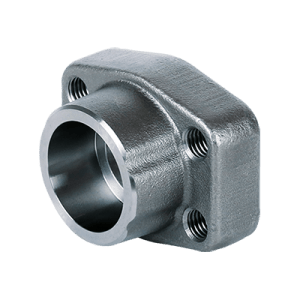

The advantages of titanium forgings include:

High Strength-to-Weight Ratio: Titanium forgings offer exceptional strength while remaining lightweight, making them ideal for high-performance applications in aerospace and automotive industries.

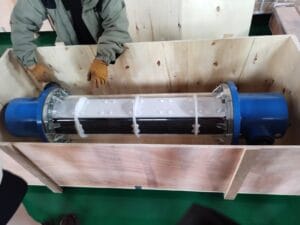

Corrosion Resistance: Titanium’s natural resistance to corrosion from seawater, chemicals, and extreme environments ensures durability and long service life in demanding applications.

Enhanced Durability: Forged titanium components are highly resistant to fatigue, wear, and impact, ensuring long-lasting performance in harsh conditions.

Heat Resistance: Titanium forgings maintain their strength and structural integrity at high temperatures, making them suitable for aerospace engines and industrial applications.

Biocompatibility: In medical applications, titanium forgings are biocompatible, making them ideal for surgical implants and prosthetics.

Precision and Customization: Titanium forgings can be precisely shaped for specific applications, providing customized solutions for complex parts in various industries.