The advantages of titanium wire include:

High Strength-to-Weight Ratio: Titanium wire offers exceptional strength while being lightweight, making it ideal for applications where both durability and weight reduction are important.

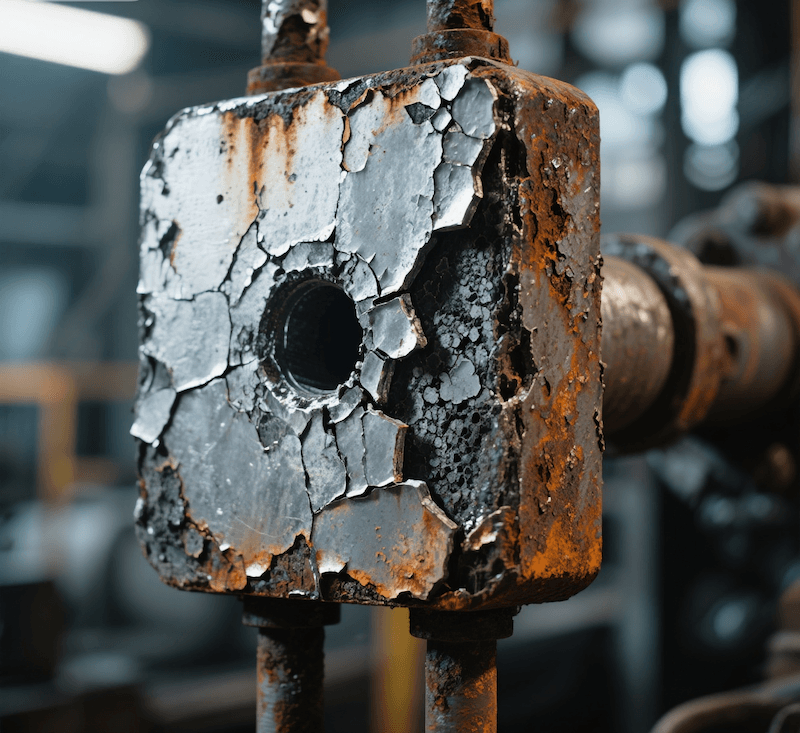

Corrosion Resistance: Titanium wire is highly resistant to corrosion from seawater, chemicals, and harsh environments, ensuring longevity in demanding conditions.

Biocompatibility: Titanium wire is non-toxic and biocompatible, making it safe for use in medical implants and surgical devices.

Durability: Titanium wire is tough and resistant to wear and fatigue, providing reliable performance in high-stress applications like aerospace, automotive, and industrial uses.

Heat Resistance: Titanium wire retains its strength and structure at high temperatures, making it suitable for welding and other high-temperature environments.

Flexibility and Formability: Titanium wire is easily shaped and formed, making it versatile for applications ranging from fasteners to springs and welding filler material.