Titanium Products for Chemical Industry

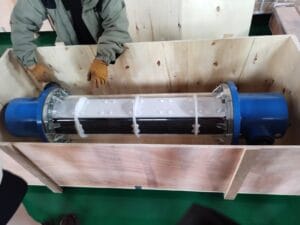

Our titanium products for the chemical industry offer superior corrosion resistance, strength, and durability, making them ideal for use in harsh chemical environments. Commonly used in reactors, heat exchangers, and piping systems, these titanium products ensure long-term reliability, reducing maintenance costs and enhancing safety in chemical processing.

Product Summary:

The advantages of titanium alloys in the chemical industry include:

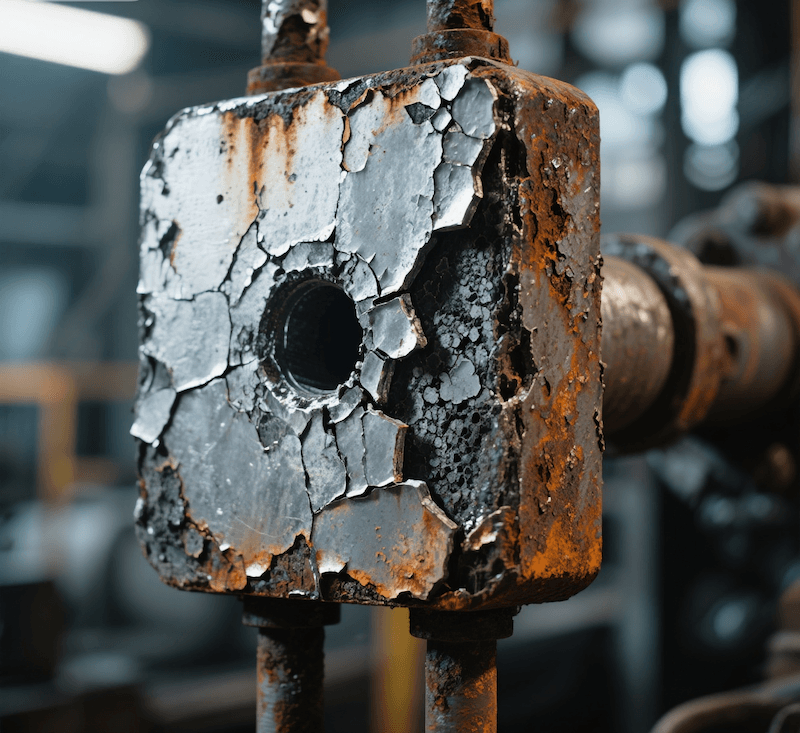

Exceptional Corrosion Resistance: Titanium alloys resist corrosion from harsh chemicals, acids, and alkalis, ensuring long-lasting performance in aggressive chemical environments.

High Strength-to-Weight Ratio: Titanium offers excellent strength while being lightweight, making it ideal for structural components that need to withstand high pressures without adding excessive weight.

Durability: Titanium alloys are highly durable and resistant to wear and fatigue, reducing the need for frequent replacements and minimizing maintenance costs in chemical processing equipment.

Compatibility with Extreme Temperatures: Titanium maintains its mechanical properties under extreme temperatures, making it suitable for high-temperature chemical reactions and processing applications.

Non-Toxic and Biocompatible: Titanium is non-toxic and safe for use in processes involving sensitive or reactive chemicals, ensuring product purity and safety.

Reduced Maintenance Costs: Due to their corrosion resistance and durability, titanium alloys require less maintenance and have a longer lifespan than traditional materials, leading to lower operational costs over time.

Chemical industry titanium alloys are widely applied in various critical areas, including:

Heat Exchangers: Titanium is ideal for heat exchangers due to its resistance to corrosive chemicals and ability to withstand high temperatures, ensuring efficient heat transfer in chemical processing.

Piping Systems: Titanium alloys are used in piping systems that transport corrosive substances, offering long-term durability and resistance to wear and corrosion.

Reactors and Pressure Vessels: Titanium alloys are commonly used in chemical reactors and pressure vessels where exposure to harsh chemicals and high pressures demands superior corrosion resistance and strength.

Pumps and Valves: Titanium components in pumps and valves help ensure smooth operation in environments involving aggressive chemicals, reducing the risk of leaks and corrosion damage.

Storage Tanks: Titanium is used in chemical storage tanks for handling corrosive liquids and gases, providing long-lasting protection against material degradation.

Agitators and Mixers: Titanium is applied in agitators and mixers in chemical plants due to its durability and resistance to corrosive media, ensuring longer service life and reduced maintenance.

In the chemical industry, the most commonly used grades of titanium are:

Grade 2: Known for its excellent corrosion resistance and moderate strength, Grade 2 is widely used in heat exchangers, piping systems, and chemical processing equipment exposed to harsh chemicals and corrosive environments.

Grade 7: With the addition of palladium, Grade 7 offers enhanced corrosion resistance, particularly in acidic environments, making it ideal for chemical reactors, pressure vessels, and storage tanks.

Grade 12: Grade 12 titanium has superior resistance to both corrosion and high temperatures, making it suitable for applications such as heat exchangers and chemical processing equipment where both heat and aggressive chemicals are present.

Grade 5 (Ti-6Al-4V): This alloy combines high strength with good corrosion resistance and is used in more demanding applications, such as high-pressure chemical reactors and processing components.

Grade 16: Known for its exceptional corrosion resistance in both oxidizing and reducing environments, Grade 16 is often used in applications involving chemical acids and chloride solutions.

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts