Titanium Products for Petroleum Industry

Our titanium products for the petroleum industry offer exceptional corrosion resistance, durability, and strength, making them ideal for offshore drilling, subsea pipelines, and refining equipment. These products ensure long-term reliability in harsh environments, reducing maintenance and operational costs while enhancing safety and performance.

Product Summary:

The advantages of titanium alloys in the petroleum industry include:

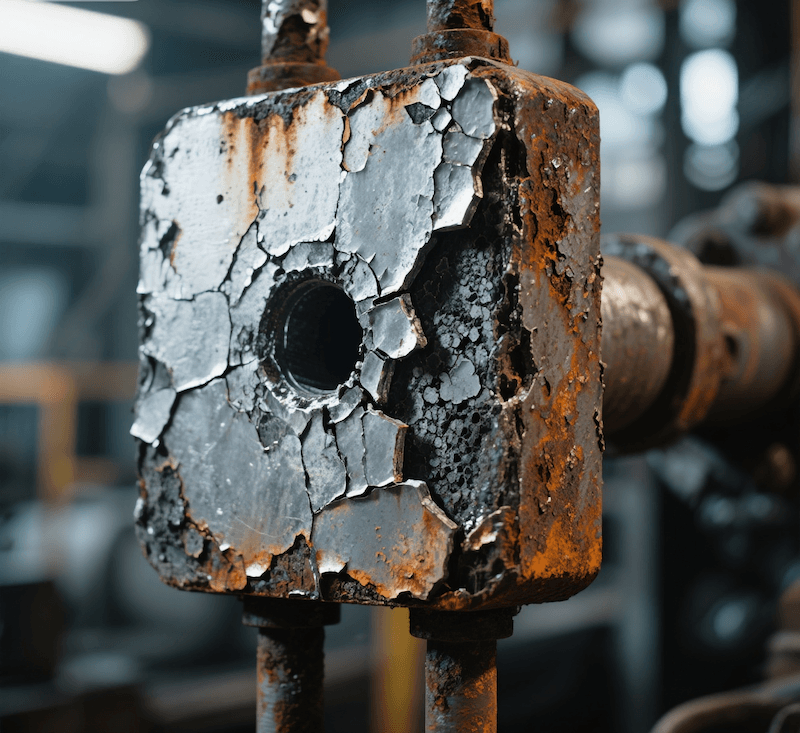

Exceptional Corrosion Resistance: Titanium alloys resist corrosion from seawater, chemicals, and harsh environments, making them ideal for offshore and subsea applications.

High Strength-to-Weight Ratio: Titanium provides excellent strength while being lightweight, reducing structural load on equipment and improving efficiency in drilling and refining operations.

Durability: Titanium alloys offer long-term durability, ensuring reliable performance in extreme conditions, such as high pressures and temperatures in deep-sea drilling.

Reduced Maintenance Costs: Due to their corrosion resistance and durability, titanium alloys require less frequent maintenance, leading to lower operational costs over time.

Compatibility with Harsh Chemicals: Titanium can withstand exposure to corrosive chemicals used in petroleum processing, ensuring the longevity of refining equipment and components.

High Heat Resistance: Titanium alloys maintain their structural integrity at elevated temperatures, making them suitable for high-temperature environments in refining and processing.

Petroleum industry titanium alloys are widely applied in various critical areas, including:

Offshore Drilling Platforms: Titanium alloys are used in offshore rigs due to their superior corrosion resistance to seawater, ensuring long-term durability in harsh marine environments.

Subsea Pipelines: Titanium is ideal for subsea pipelines where exposure to corrosive saltwater and high pressure demands materials with excellent corrosion resistance and strength.

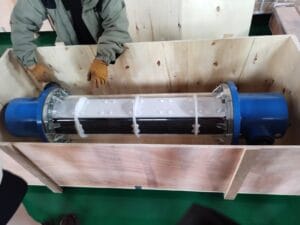

Heat Exchangers: Titanium is commonly used in heat exchangers for its ability to withstand corrosive fluids and high temperatures, ensuring efficient thermal management in refining processes.

Downhole Tubing and Casings: Titanium alloys are used in downhole tubing and well casings due to their strength and ability to resist corrosive environments deep below the Earth’s surface.

Chemical Processing Equipment: Titanium is used in valves, pumps, and fittings that come into contact with harsh chemicals in petroleum processing, ensuring longer equipment life and reduced maintenance.

Desalination Plants: Titanium alloys are employed in desalination plants associated with the petroleum industry, where they resist corrosion from saltwater and ensure efficient, long-lasting operation.

In the petroleum industry, the most commonly used grades of titanium are:

Grade 2: Known for its excellent corrosion resistance and moderate strength, Grade 2 is widely used in offshore platforms, heat exchangers, and subsea pipelines where durability in harsh environments is essential.

Grade 5 (Ti-6Al-4V): This alloy offers high strength and corrosion resistance, making it suitable for critical applications such as downhole tubing, casings, and equipment exposed to high pressures and temperatures.

Grade 7: With added palladium, Grade 7 offers enhanced corrosion resistance in highly corrosive environments, such as those involving aggressive chemicals and seawater, making it ideal for chemical processing and subsea applications.

Grade 12: Known for its superior resistance to corrosion in hot, highly acidic environments, Grade 12 is often used in heat exchangers, pressure vessels, and chemical processing equipment.

Grade 9 (Ti-3Al-2.5V): This alloy provides a good balance of strength, corrosion resistance, and formability, making it suitable for piping systems and components used in both onshore and offshore petroleum applications.

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts