Titanium Products for Medical Industry

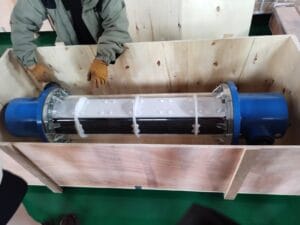

Our titanium products for the medical industry provide superior strength, biocompatibility, and corrosion resistance. Perfect for implants, surgical tools, and medical devices, they are crafted with precision to meet the highest safety and performance standards in healthcare.

Product Summary:

The advantages of titanium alloys in the medical industry include:

Biocompatibility: Titanium alloys are highly biocompatible, meaning they are well-tolerated by the human body, making them ideal for implants and prosthetics.

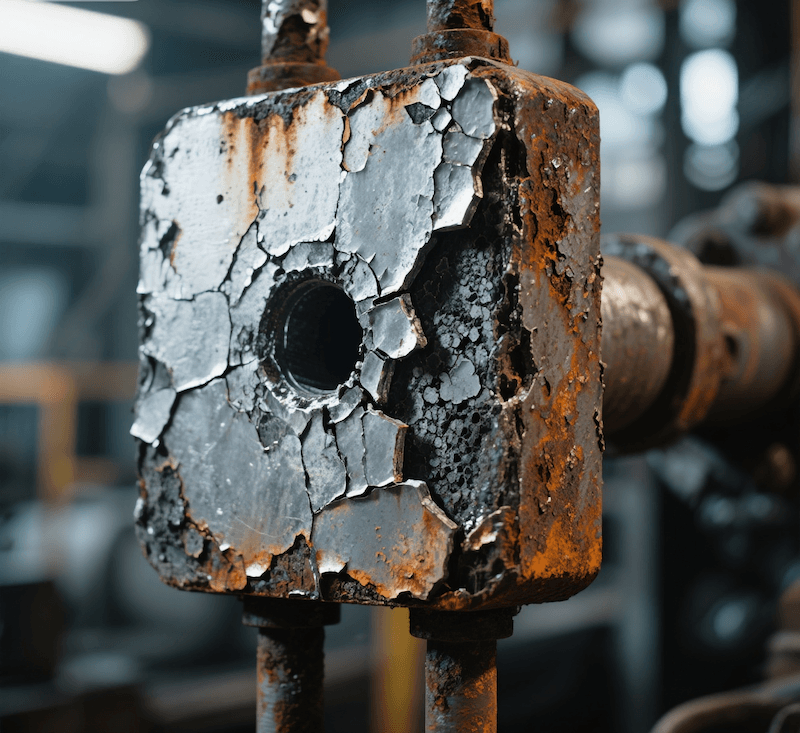

Corrosion Resistance: Titanium alloys resist corrosion from bodily fluids, ensuring long-term stability and reliability in medical devices and implants.

High Strength-to-Weight Ratio: Titanium alloys offer exceptional strength while being lightweight, reducing the burden on patients, especially in implants.

Non-Magnetic: Titanium is non-magnetic, making it safe for use in MRI environments and other medical imaging technologies.

Durability: The exceptional durability of titanium alloys ensures that medical devices and implants can last for extended periods without degradation.

Osseointegration: Titanium alloys promote the natural bonding of bone tissue, which is crucial for the success of implants like dental and orthopedic devices.

Medical industry titanium alloys are widely applied in various critical areas, including:

Orthopedic Implants: Used in joint replacements, bone plates, and screws due to their biocompatibility, strength, and ability to promote bone growth.

Dental Implants: Titanium alloys are a top choice for dental implants because of their ability to integrate with bone tissue (osseointegration) and long-term durability.

Surgical Instruments: Titanium’s lightweight and corrosion-resistant properties make it ideal for producing high-precision surgical tools that can withstand repeated sterilization.

Cardiovascular Devices: Titanium alloys are used in heart valves, pacemaker cases, and stents due to their non-reactive and biocompatible nature.

Spinal Fixation Devices: Titanium is used in spinal rods and cages to support and stabilize the spine in patients with spinal disorders.

Cranial and Maxillofacial Applications: Titanium plates and screws are used for reconstructive surgeries in the skull and face due to their strength and biocompatibility.

In the medical industry, the most commonly used grades of titanium are:

Grade 1: Known for its high purity and excellent corrosion resistance, Grade 1 titanium is often used in medical implants and surgical devices where formability and biocompatibility are crucial.

Grade 2: Offering a balance of strength and corrosion resistance, Grade 2 is frequently used for dental implants, surgical instruments, and orthopedic implants.

Grade 5 (Ti-6Al-4V): The most widely used titanium alloy in the medical field, Grade 5 is favored for its superior strength, light weight, and high biocompatibility. It’s commonly found in joint replacements, dental implants, and surgical tools.

Grade 23 (Ti-6Al-4V ELI): An extra-low interstitial version of Grade 5, Grade 23 is used in critical medical applications like implants and prosthetics, offering enhanced fracture toughness and excellent compatibility with the human body.

Quality Assurance

Ensures all products meet stringent quality standards before distribution.

Responsive Service

Offers prompt and effective solutions to any operational or product issues.

Timely Delivery

Prioritizes efficient logistics to guarantee on-time delivery of orders.

Sourcing Titanium Can Be Simple & Secure

Whatever your titanium product requirements, our deep expertise ensures we can manufacture it to your exact specifications. By producing our own raw materials, we maintain superior quality control and offer more competitive pricing than our global competitors.

Still Have A Questions?

If you have any additional questions, feel free to reach out to us directly. We’re here to assist you with all your inquiries

Uncover Exclusive Insights in Our Specialized Industries

Explore how our advanced materials, including titanium and triply cookware circles, are transforming industries. Our solutions enhance efficiency, durability, and innovation across multiple sectors.

Recent Posts